Views: 222 Author: Amanda Publish Time: 2025-10-13 Origin: Site

Content Menu

● What is a 3D Print Prototype?

● Advantages of 3D Print Prototypes

>> Cost-Effectiveness for Low Volume

>> Design Flexibility and Complexity

>> Material Variety and Functional Testing

>> Reduced Waste and Sustainability

● Comparing with CNC Machining Prototypes

>> Precision and Surface Finish

>> Material Strength and Realism

● Traditional Prototyping Methods

● When to Choose a 3D Print Prototype

● When to Choose Other Prototyping Methods

● Advantages of Using OEM 3D Printing Services

● FAQ

>> 1. What materials can be used for 3D print prototypes?

>> 2. How fast can I get a 3D print prototype?

>> 3. Can 3D print prototypes be used for functional testing?

>> 4. When is CNC machining preferred over 3D printing for prototyping?

>> 5. Are 3D print prototypes more environmentally friendly than traditional prototypes?

Prototyping plays a pivotal role in the journey from concept to finished product, offering a tangible glimpse of design functionality, form, and potential improvements. Among the various prototyping methods, 3D print prototypes have gained significant traction for their versatility, speed, and cost-effectiveness. Yet, traditional methods like CNC machining, injection molding, and handcrafted models continue to hold relevance depending on project requirements. This article dives deep into the differences, advantages, and ideal use cases of 3D print prototypescompared to other techniques, empowering designers, manufacturers, and OEM service providers with informed decision-making capabilities.

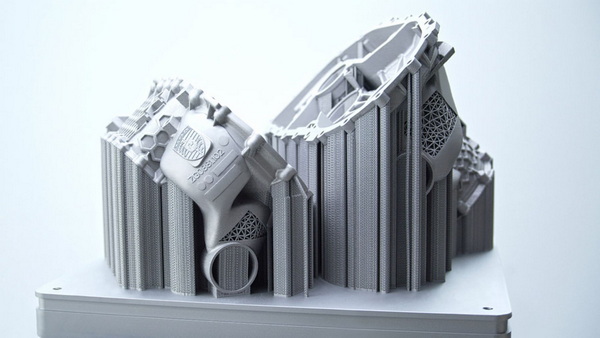

A 3D print prototype is a physical model created using additive manufacturing technologies where material is deposited layer by layer according to a digital 3D model. Popular 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF), among others. These methods support a broad range of materials from durable plastics to resins with different finishes, allowing the production of highly detailed and functional prototypes.

One of the standout benefits of 3D print prototypes is the exceptionally fast turnaround time. Unlike traditional prototyping which may require tooling, machining setups, or molds, 3D printing can produce a prototype within hours or a few days based purely on digital files. This facilitates rapid design iterations, enabling designers and engineers to test and refine product concepts quickly.

For low-volume prototyping, 3D print prototypes are generally more affordable because there are no upfront tooling costs. Traditional manufacturing methods often incur significant setup expenses, making them ideal for large production runs but less economical for prototypes or short runs.

3D printing excels in creating complex geometries and intricate details that would be challenging or impossible with conventional methods. Features like internal channels, lattices, and overhangs can be easily realized, thus enabling advanced functional prototypes and parts that push innovation boundaries.

While 3D printing predominantly uses plastics and resins, the technology continuously evolves to include more durable and engineering-grade materials. This broadens the scope of prototypes from purely visual models to functional parts tested for strength, heat resistance, or wear, depending on the material used.

Additive manufacturing is inherently less wasteful than subtractive methods like CNC machining, which remove material from a larger block. By building only the material that makes up the part, 3D print prototypes contribute to more sustainable manufacturing with less scrap.

CNC machining uses cutting tools to carve parts out of solid blocks of metal or plastic, offering very high precision and superior surface finishes. For prototypes requiring tight tolerances or metal parts, CNC machining remains a preferred method.

CNC prototypes can be made from actual end-use materials including metals, whereas 3D printing materials may not fully replicate the mechanical properties of production materials. This makes machining a better choice for prototypes that will undergo functional stress testing or represent true product conditions.

CNC machining has higher upfront costs due to tooling and programming, and it is less adaptable to design changes mid-process. For single or few prototypes with moderate complexity, CNC may be more expensive and slower than 3D printing.

Handcrafted models, vacuum casting, and injection molding have been prototyping mainstays for decades. These methods provide benefits such as realistic textures and finishes and are suitable for certain plastics and metals, but often require longer lead times and higher initial investment, especially for injection molding tooling.

- When quick design iteration and rapid prototyping are critical.

- For complex geometries that are difficult or expensive to machine or mold.

- When project budgets necessitate lower initial costs with minimal setup.

- For visual prototypes, form and fit testing, and some functional testing using specialized materials.

- When sustainability and material efficiency are a priority.

- When high precision, superior surface finishes, or prototype materials identical to production parts are required.

- For functional testing under extreme conditions like high stress or temperature.

- When producing larger prototype quantities where per-piece cost savings offset tooling expenses.

- For prototypes demanding realistic appearance and texture that mimic market-ready products.

Many manufacturing companies, including leading OEM service providers, now incorporate 3D print prototypes within their service portfolios. This combination offers benefits such as:

- Access to expert design and engineering feedback in prototyping.

- Seamless transition from prototype to batch production using compatible processes.

- Support for multiple prototyping technologies under one roof, providing tailored solutions.

- Cost and time efficiencies by integrating rapid prototyping with downstream manufacturing processes.

Deciding between a 3D print prototype and other prototyping methods requires careful consideration of project objectives, budget, timeline, and product requirements. 3D printing empowers flexible, rapid, and cost-effective prototyping that fosters innovation and fast product development cycles. However, traditional methods like CNC machining still hold key advantages for high precision, material realism, and functional testing. Combining these technologies strategically, especially through skilled OEM service partnerships, provides a comprehensive prototyping solution tailored to any manufacturing need.

3D print prototypes can be made from various plastics, resins, and some advanced materials like nylon or photopolymers. Emerging technologies also offer metal 3D printing options suitable for functional prototypes.

Depending on complexity and size, 3D print prototypes can be delivered in hours to a few days, enabling quick design iterations.

Yes, with certain engineering-grade materials, 3D printed prototypes can undergo some levels of functional and stress testing, though not always equivalent to final production materials.

CNC machining is preferred when prototypes require high precision, metal materials, superior surface finishes, or must mimic the final product material properties.

Generally, yes. 3D printing produces less material waste since it adds material layer-by-layer, unlike subtractive methods that cut away excess material.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product