Views: 222 Author: Amanda Publish Time: 2025-10-25 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

>> What Is Vacuum Mold Casting?

>> Advantages of Vacuum Mold Casting

>> How Vacuum Mold Casting Works

● The Role of 3D Printing in Prototype Development

>> Accelerating Design Iteration

>> Common 3D Printing Processes Used in Mold Casting

● Integrating 3D Printing with Vacuum Mold Casting

>> Material Selection for the Master Model

>> Medical and Healthcare Devices

● Enhancing Efficiency with Digital Manufacturing

>> Integration with CNC Machining

>> Automation and AI Design Optimization

>> Sustainable Manufacturing Approaches

● Challenges and Solutions in Integration

● Expanding Product Design Possibilities

● Frequently Asked Questions (FAQ)

>> 1. How does Vacuum Mold Casting support rapid product development?

>> 2. What is the typical mold lifespan?

>> 3. What types of materials can be cast using this method?

>> 4. Can this method be used for end-use production parts?

>> 5. How cost-effective is it compared to injection molding?

In modern manufacturing, speed and precision are the cornerstones of success. As industries evolve and product life cycles shorten, the demand for rapid product development has never been greater. Manufacturers are constantly seeking methods that reduce lead times, improve quality, and maintain cost efficiency. Among these innovative solutions, the integration of 3D printing with Vacuum Mold Casting stands out as one of the most effective strategies for producing high-quality prototypes and short-run parts.

At Shangchen (sc-rapidmanufacturing.com), we specialize in rapid prototyping, CNC machining, sheet metal fabrication, 3D printing services, and mold production. By merging 3D printing technology with Vacuum Mold Casting, we enable global brands, wholesalers, and OEM clients to realize their product ideas quickly and efficiently. This article explores how these two technologies complement each other to revolutionize the design-to-production process.

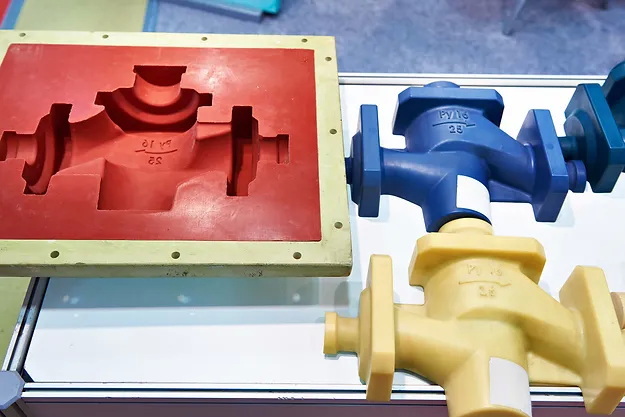

Vacuum Mold Casting is a manufacturing process used primarily for producing small to medium quantities of functional prototypes and end-use parts. The technique involves creating a silicone mold around a master model—often produced via 3D printing—and using vacuum pressure to draw liquid resin or other materials into the mold for precise replication. Because the process removes trapped air and eliminates imperfections, the final parts exhibit superior surface finish and dimensional accuracy.

- High surface quality with minimal defects

- Excellent repeatability for consistent batches

- Short production lead times with flexible mold adjustment

- Lower tooling cost compared to traditional metal molds

- Support for diverse materials, including flexible and rigid forms

This efficiency makes Vacuum Mold Casting ideal for industries that demand precision and agility, such as automotive, consumer electronics, aerospace, and healthcare.

1. Master Model Creation: The initial master is produced, typically through SLA or SLS 3D printing.

2. Mold Preparation: Silicone material is poured around the master inside a mold box.

3. Curing and Removal: Once cured, the silicone mold is cut open, and the master is removed.

4. Casting Process: The mold cavity is filled with polymer resin under vacuum conditions to eliminate bubbles and ensure surface fidelity.

5. Post-Processing: The cast parts undergo trimming, sanding, or painting for final use.

3D printing, or additive manufacturing, has transformed the prototyping landscape by enabling almost instant production of complex shapes without conventional tooling. Unlike subtractive methods, 3D printing builds objects layer by layer from a digital file, allowing designers to test multiple iterations quickly.

- Stereolithography (SLA): Ideal for creating smooth, detailed master patterns.

- Selective Laser Sintering (SLS): Used for functional prototypes with strong mechanical properties.

- Fused Deposition Modeling (FDM): Common for cost-effective conceptual molds.

- Digital Light Processing (DLP): Frequently employed for intricate parts and miniaturized features.

When combined with Vacuum Mold Casting, 3D printing becomes the bridge between design and production, drastically reducing the time to market.

The synergy between these two processes lies in combining the customizable capabilities of 3D printing with the reproducibility and finish of vacuum casting. The workflow follows these essential steps:

1. Design Optimization: Engineers model the part using CAD software and optimize geometry for casting.

2. 3D Printing Master Creation: The master model is 3D printed using a suitable material, ensuring the right balance between rigidity and surface smoothness.

3. Mold Fabrication: The printed master is embedded in silicone or a flexible polymer to form the mold.

4. Vacuum Casting: Liquid urethane or epoxy resin is poured into the mold under vacuum conditions, allowing precise detail replication.

5. Demolding and Finishing: After solidification, parts are removed, finished, and inspected to ensure accuracy.

This method ensures flexibility, allowing for quick adaptation in design, shorter production times, and reduced waste.

The master model's durability and surface quality directly influence the outcome of the Vacuum Mold Casting process. Preferred materials include:

- Resin (SLA): Excellent for smooth surfaces and fine details.

- Nylon (SLS): Tough and heat-resistant for repetitive molding.

- ABS (FDM): Affordable and easy to handle for test prototypes.

The choice of casting material determines mechanical strength, durability, and appearance:

- Polyurethane: Provides flexible or rigid outputs; ideal for functional parts.

- Epoxy Resin: Offers high dimensional stability and chemical resistance.

- Silicone Rubber: Suitable for soft-touch or overmold applications.

Typical silicone molds can produce between 15 to 30 castings before degradation. Proper curing conditions, mold release application, and controlled temperature can extend mold life, offering high efficiency for low-volume production.

Feature | Traditional Tooling | 3D Printing + Vacuum Mold Casting |

Tooling Cost | Very High | Low to Moderate |

Production Lead Time | 8–12 Weeks | 1–3 Weeks |

Surface Finish | Excellent | Excellent |

Design Flexibility | Limited | High |

Suitable Volume | High | Low to Medium |

Material Options | Metal, Plastic | Polyurethane, Epoxy, Silicone |

By combining both techniques, manufacturers achieve near-injection-mold quality parts without the lengthy lead times or high initial setup costs.

Automotive prototyping demands parts that mimic production material behavior. Vacuum Mold Casting enables manufacturers to produce functional dashboards, grips, and connectors from thermoset materials while testing designs before committing to injection molds. Using 3D printing for masters reduces lead time from weeks to days.

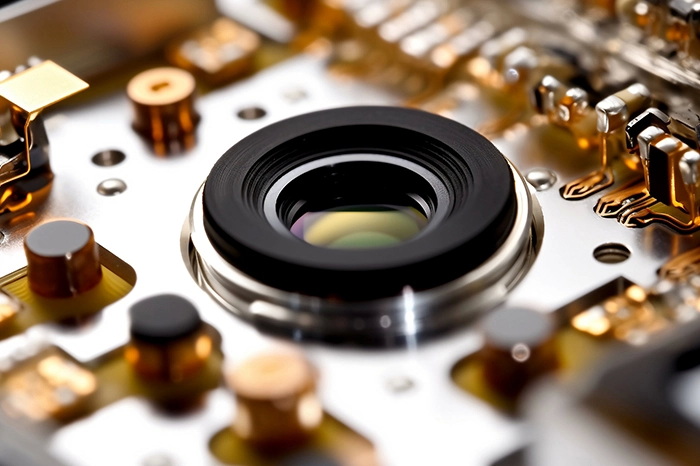

Manufacturers of wearable gadgets, smartphones, and household accessories rely heavily on appearance and ergonomics. The integration of 3D printed masters and Vacuum Mold Casting delivers precise textures and dimensions for both functional and aesthetic testing.

In aerospace applications where reliability is critical, the process supports low-volume production of lightweight yet durable composite components. The vacuum environment prevents defects, while 3D printing ensures structural innovation.

This hybrid method enables small-batch production of biocompatible prototypes, surgical tools, and housings for diagnostic machinery. Silicone molds allow flexibility in design while maintaining safety standards.

Beyond 3D Printing and Vacuum Mold Casting, incorporating CNC machining into post-processing further refines product outcomes. Machining ensures tight tolerances for mating parts and adds high-precision holes or slots.

With advancements in manufacturing automation and artificial intelligence, digital modeling software can now predict structural weaknesses, optimize material use, and simulate vacuum casting behavior before production begins. This optimization minimizes manual errors and material waste.

Modern manufacturing practices are increasingly leaning toward sustainability. Using Vacuum Mold Casting with 3D printed masters minimizes waste material, supports recyclable silicone molds, and eliminates the need for costly metal tooling, thereby reducing environmental impact.

1. Thermal Expansion Mismatches: Different material shrinkage rates between the 3D printed master and cured resin can cause dimensional errors.

2. Surface Imperfections: Layer lines from 3D printing may appear in the final cast.

3. Mold Wear and Deformation: Overuse or insufficient curing time can reduce mold accuracy over cycles.

- Applying professional-grade surface coating or smoothing to printed masters.

- Controlling process temperature and humidity to reduce resin shrinkage.

- Using reinforcement inserts in silicone molds for larger parts.

Through these measures, manufacturers can ensure consistent performance across multiple production cycles.

The combination of 3D printing and Vacuum Mold Casting encourages creative freedom and design complexity. Custom geometries, ergonomic modifications, and intricate internal channels become achievable without conventional manufacturing limits. The resulting prototypes are not just display models—they are often functional testing samples suitable for mechanical and aesthetic validation.

Design teams can thus transition seamlessly from concept to production-ready components, reducing the feedback loop between design, manufacturing, and quality control departments.

Integrating 3D Printing with Vacuum Mold Casting represents a new standard in rapid product development. The collaboration of digital design flexibility with the precision of vacuum casting enables companies to deliver prototypes and short-run parts that rival injection-mold quality while significantly reducing lead times and cost barriers.

At Shangchen, we leverage both technologies to help global clients achieve highly detailed, production-ready parts quickly. This fusion fosters innovation, accelerates design verification, and bridges the gap between prototyping and full-scale production. As digital manufacturing continues to evolve, the union of these two technologies will redefine what's possible for engineers and product developers worldwide.

Vacuum Mold Casting uses vacuum pressure to remove air bubbles and accurately fill molds, significantly improving surface quality and detail precision. When paired with 3D printed masters, it cuts down lead time to just weeks while maintaining production-grade quality.

A silicone mold typically lasts for about 15–30 production cycles depending on material type, curing parameters, and complexity. For high-fidelity parts, manufacturers often create multiple molds to maintain consistent quality.

The most common materials include polyurethane, epoxy, ABS-like resin, and flexible silicone. Each provides varying levels of rigidity, temperature resistance, and impact strength to simulate final production materials.

Yes. Many industries use the 3D printing and Vacuum Mold Casting combination for small-volume end-use products where traditional tooling is not cost-effective. It's especially practical for startups and R&D departments.

The cost of tooling for Vacuum Mold Casting is a fraction of that for injection molds. While per-part costs are slightly higher at scale, the overall investment and turnaround time are dramatically lower for low-to-medium production volumes.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam