Views: 222 Author: Amanda Publish Time: 2025-10-29 Origin: Site

Content Menu

● Understanding CNC Milling Services

● Key Cost Drivers in CNC Milling Services

>> Machining Time and Part Complexity

>> Material Choice and Machinability

>> Volume, Batch Size, and Production Runs

>> Machine Type, Equipment, and Accuracy

>> Setup, Programming, and Tooling

>> Surface Finish and Post-Processing

>> Quality Control and Certification

>> Lead Time and Delivery Requirements

>> Tool Wear, Maintenance, and Upkeep

● Advanced Tips for Cost Optimization in CNC Milling Services

● CNC Milling Services: Real-World Price Structures

● OEM Strengths: CNC Milling Services at Shangchen

● Practical Insights for International Buyers

● Frequently Asked Questions (FAQ)

>> 1. What are the most significant factors that affect CNC Milling Services cost?

>> 2. How can buyers optimize CNC Milling Services costs?

>> 3. Are post-machining finishing services necessary for every project?

>> 4. How does working with certified suppliers impact pricing and quality?

>> 5. Can international buyers request small-batch or prototype CNC jobs?

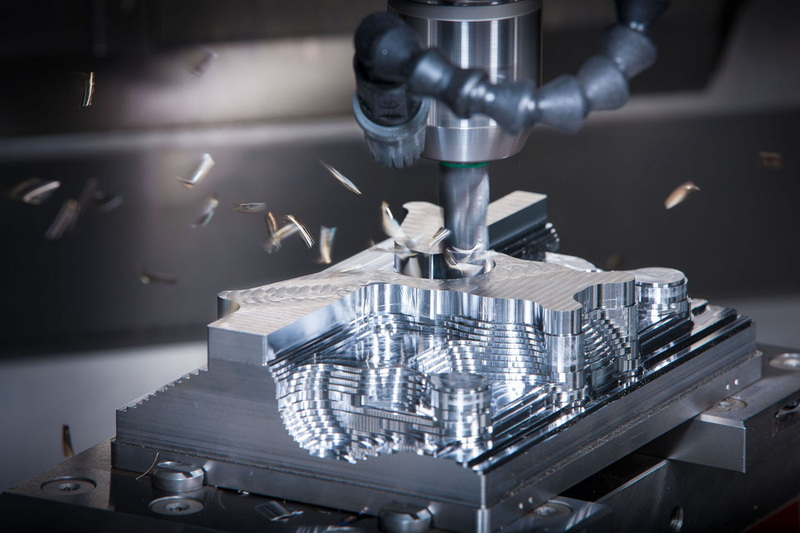

CNC Milling Services have become a cornerstone of industrial manufacturing globally, providing unprecedented precision, flexibility, and adaptability across sectors like automotive, medical devices, consumer electronics, and aerospace. As international demand for custom-machined components accelerates, buyers, brand owners, and OEM procurement managers must understand the myriad factors that shape CNC milling costs to maximize their investments and avoid procurement surprises. This guide leverages current industry expertise and practical tips to illuminate cost drivers in CNC Milling Services, empowering you to make informed decisions for prototyping, batch production, or full-scale manufacturing.[1][3][11][12][13]

CNC Milling Services use computer-numerical-control (CNC) machinery to automate the removal of material from workpieces, achieving precise, complex geometries through programmed pathways and multi-axis movement. These services support the creation of everything from one-off prototypes to thousands of production-grade parts, accommodating both metals and plastics thanks to modern, high-speed spindle technology and advanced toolpaths. Standard CNC milling centers feature three, four, or five axes of motion, enabling sophisticated strategies required for modern industry standards.[2][3][11][13][14]

The CNC milling process unfolds in several stages:

- CAD modeling and engineering design

- Programming and conversion to G-code or other machine languages

- Setup and fixturing

- Automated manufacturing

- Inspection and post-processing

Sophisticated CNC mills—like those employed by top-tier OEM suppliers—offer high positional accuracy and repeatability crucial for medical, aerospace, and technical applications, while also flexibly supporting rapid prototyping for design cycles.[12][15]

The principal variable in CNC milling pricing is machining time, directly linked to part complexity and design. Simple components require fewer tool movements, less programming, and shorter set-ups, translating to lower per-part rates. By contrast, complex parts featuring undercuts, deep cavities, tight tolerances, and multiple surfaces may require hours of intricate multi-axis programming, tool changes, and repeated inspection, driving up both time and cost.[3][4][6][16][1]

Material selection profoundly impacts both the raw material cost and the difficulty of machining. Common, easy-to-machine metals like aluminum or some plastics keep the rate lower, while harder materials—stainless steel, titanium, engineering polymers, or superalloys—require longer machining cycles and specialized (often more expensive) tooling, which increases costs. Critical material aspects to consider:[4][6][1][3]

- Base price per kilogram/pound

- Machinability affecting tool wear and processing time

- Waste generated from cutting and shaping

- Market availability and volatility of raw stock

Specialty or certified grades (for aerospace or medical) may further add price due to compliance and traceability requirements.[6][13]

Order volume is a decisive factor in CNC Milling Services pricing structure. Large batch sizes permit economies of scale, diluting initial setup costs and reducing per-unit pricing. Small volumes or prototypes sometimes appear disproportionately costly as setup, fixturing, and programming are spread across few parts. International OEM buyers seeking samples, low-volume pilot runs, or mass production can expect per-piece rates to fall as batch size increases.[7][15][16][1][3][6][12]

The selection of machine tool (3-axis, 4-axis, 5-axis) and ancillary equipment such as high-precision metrology tools impacts hourly rates and achievable tolerances. Advanced multi-axis equipment, required for complex features and sub-millimeter accuracy, commands premium rates due to higher machine costs and operating complexity. Parts needing stringent accuracy or custom machinery (like medical, aerospace, or automotive components) rise in price as a result.[5][13][17][2][3][6]

Every new part or design incurs labor costs for programming toolpaths, designing fixtures, and selecting or fabricating custom tooling. Specialized features may even require unique cutters, jigs, or modular fixtures which add upfront expense. These costs are divided across production batch size, keeping prototype and small-volume jobs relatively expensive.[8][1][3][5][6]

Post-machining steps such as polishing, plating, anodizing, powder coating, painting, bead blasting, or heat treatment further contribute to CNC Milling Services pricing. The type and complexity of finishing drive costs, as some methods require additional equipment, labor, or specialty treatments. These may be mandated by application requirements—medical, electronics, consumer goods often need precise cosmetic or functional finishes.[13][16][6]

Rigorous inspection processes, certifications (ISO9001, ISO/IEC27001, CE marking), and traceability required by international buyers add QC-related expenses to CNC jobs. Factories employing Coordinate Measuring Machines (CMM), 3D scanning, and advanced metrology provide higher-quality assurance but typically charge more for these capabilities.[15][6][12][13]

Express jobs, expedited lead times, and urgent production requests (such as medical or emergency spare parts) typically result in premium pricing. Efficient suppliers balance speed and quality, but last-minute changes and rapid delivery always introduce surcharges due to overtime and resource allocation shifts.[12][13]

Skilled technicians, engineers, and inspection staff are pivotal for high-precision CNC Milling Services, impacting labor costs, especially in markets with high wage standards. Overheads like factory maintenance, training, safety, inventory management, and utility expenses are factored into per-job pricing by professional OEM factories.[1][6][12]

Frequent tool changes and maintenance—especially on difficult-to-machine materials—lead to increased operational costs and downtime, which impactful suppliers must account for in their pricing models. Proper upkeep ensures consistent product quality and cost-effective manufacturing, while neglected equipment leads to scrap, wasted materials, and financial loss.[4][6]

- Work with your supplier to optimize part geometry, avoiding unnecessary complexity, tight internal features, or non-standard dimensions unless critical for function.[17][6]

- Standardize tolerances to the lowest necessary for performance, reducing inspection time and scrap rates.[6][8]

- Consider alternative materials—select for machinability and availability unless your application absolutely requires high-end alloys.[3][4]

- Batch orders together to maximize economies of scale and minimize per-part setup costs.[7][6][12]

- Ask your CNC Milling Services provider for detailed cost breakdowns and transparency in quoting practices, avoiding hidden fees or surprise charges.[18][5]

- Evaluate finishing options critically; only specify surface treatments that the end use demands, as these add additional labor and material expense.[6]

- Communicate design changes early, as late modifications often increase costs due to re-programming, fixturing, or material wastage.[8][1]

- Consider working with well-established OEMs like Shangchen that offer robust technical support, in-house design review, QC certification, and efficient production flows for maximum value and reliability.[19][15][12]

Understanding real price ranges can help set expectations and negotiate better deals:

- Prototyping: $500 – $2,000+ per part depending on design, material, and setup.[20][3]

- Batch Production: $10 – $160 per part, influenced heavily by volume, material, and complexity.[5][1]

- Hourly Rates:

- 3-Axis Mill: $40/hr

- 4-Axis: $45–50/hr

- 5-Axis: $75–120/hr (more complex shapes and tolerances).[5]

- Surface Finishing: $0.10–$1.50 per part for standard treatments; specialty finishes may cost more.[13][12]

- Tooling/Setup: Spreads across job size, so expect higher costs per part for low-volume runs.[3][8]

These prices fluctuate based on supplier, job requirements, and geographic region.

Shangchen (sc-rapidmanufacturing.com) distinguishes itself in the global CNC Milling Services market via:

- Advanced multi-axis machine center fleet for complex prototypes and volume production;[12][13]

- Capabilities in aluminum, steel, titanium, engineering plastics, and exotic alloys;

- Full suite of secondary processing: anodizing, plating, powder coating, heat treating;

- Stringent international QC using high-precision metrology and standards certifications;

- Rapid lead times for urgent needs, with capacity for anything from single samples to tens of thousands of units;[15][12]

- Robust engineering support for design conversion, tolerance analysis, and manufacturability optimization;[19][15]

- Transparent quotes and fast international logistics for global OEM/ODM customers.[15][19][12]

For B2B buyers, working with reputable Chinese suppliers like Shangchen offers high value, reliability, and the flexibility necessary for modern supply chains.

Whether sourcing pharmaceutical prototypes, medical device enclosures, auto engineering spares, or mass-market consumer goods, global buyers should:

- Clarify part specs, tolerancing, material certification, and batch size in RFQs;

- Request supplier input on design for manufacturing to minimize cost;

- Scrutinize post-processing and surface finish requirements for necessity versus aesthetics;

- Build partnerships with CNC Milling Services providers who understand international compliance, traceability, and customs;

- Factor all overheads, freight, and QC costs into total landed price for a holistic purchasing decision.[16][1][12]

Pricing for CNC Milling Services is determined by a complex interaction among design complexity, machining time, raw material selection, production volume, machine capability, surface finishing, programming, QC requirements, and supplier expertise. By understanding and optimizing these variables—and collaborating with quality-focused, transparent OEM suppliers—buyers can achieve the best possible value in both prototyping and volume manufacturing.[16][1][6][12]

Shangchen's advanced CNC capacity, material flexibility, and robust engineering support ensure international clients receive scalable, cost-effective solutions tailored to their unique needs. Prioritizing design optimization, open communication, and supplier transparency will help buyers navigate the nuanced world of CNC Milling Services pricing and secure competitive offers for complex industrial projects.[19][15]

The primary drivers are machining time, design complexity, material selection, batch size, machine type, finishing requirements, QC processes, and supplier expertise.[16][3][6]

Simplify geometry, use standard tolerances, select cost-effective materials, order larger volumes, and work closely with experienced OEM suppliers who offer design and technical support.[17][8][12]

No, finishes should be specified based on functional and aesthetic needs. Some sectors require specific treatments (medical, electronics, automotive), but unnecessary finishing adds to cost.[13][6]

Certified suppliers like Shangchen provide rigorous quality control, material traceability, and international compliance, which may increase price but guarantee high-quality results and reliable partnerships.[12][15][19]

Yes. Professional OEMs offer flexible MOQs and are willing to handle everything from single-piece prototypes to bulk orders, with pricing scaling according to volume.[15][12]

[1](https://www.tfgusa.com/cnc-machining-cost/)

[2](https://sendcutsend.com/blog/cnc-machine-costs/)

[3](https://www.partmfg.com/cost-of-cnc/)

[4](https://jlccnc.com/blog/breaking-down-cnc-machining-costs-key-factors-and-practical-tips-to-save)

[5](https://www.unionfab.com/blog/2024/12/cost-of-cnc)

[6](https://hppi.com/knowledge-base/cnc-machining-design/cost)

[7](https://www.komacut.com/blog/how-much-does-cnc-machining-cost/)

[8](https://www.xometry.com/resources/machining/cnc-machining-cost-calculation/)

[9](https://www.cncmasters.com/cnc-machine-buyers-guide/)

[10](https://www.3erp.com/blog/cnc-milling-cost/)

[11](https://www.linkedin.com/posts/thea-du_cncmilling-precisionmachining-manufacturingtech-activity-7368531874673065985-IxWZ)

[12](https://shangchencnc.en.made-in-china.com/product/PxZUEtdKgHpo/China-on-Demand-CNC-Machining-for-Prototype-and-Production-Parts-with-Fast-Delivery-China-Export.html)

[13](https://shangchencnc.en.made-in-china.com/product/yQNYcMFxreWk/China-Rapid-CNC-Machining-Services-for-Custom-Metal-and-Plastic-Parts-China-Factory.html)

[14](https://www.youtube.com/watch?v=lEyNWtM6MW4)

[15](https://www.sc-rapidmanufacturing.com/news/OEM-CNC-Partners.html)

[16](https://jlccnc.com/blog/the-true-cost-of-cnc-machining-services-what-are-the-main-factors-affecting-price)

[17](https://fathommfg.com/cnc-machining-cost)

[18](https://elimold.com/cnc-machining-cost-structure-and-calculation-method/)

[19](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

[20](https://jcadusa.com/cnc-machining-milling-cost/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal