Views: 222 Author: Amanda Publish Time: 2025-07-09 Origin: Site

Content Menu

● Understanding Rapid Prototyping

>> Benefits of Rapid Prototyping

● Key Factors in Material Selection

● Common Materials for Rapid Prototyping

>> Plastics

>>> ABS (Acrylonitrile Butadiene Styrene)

>>> TPU (Thermoplastic Polyurethane)

>> Metals

>>> Aluminum

>>> Stainless Steel

>>> Titanium

>>> Brass and Copper

>> Composites

>>> Carbon Fiber Reinforced Polymers

>>> Silicone

>>> Wax

● Material Selection for Different Prototyping Methods

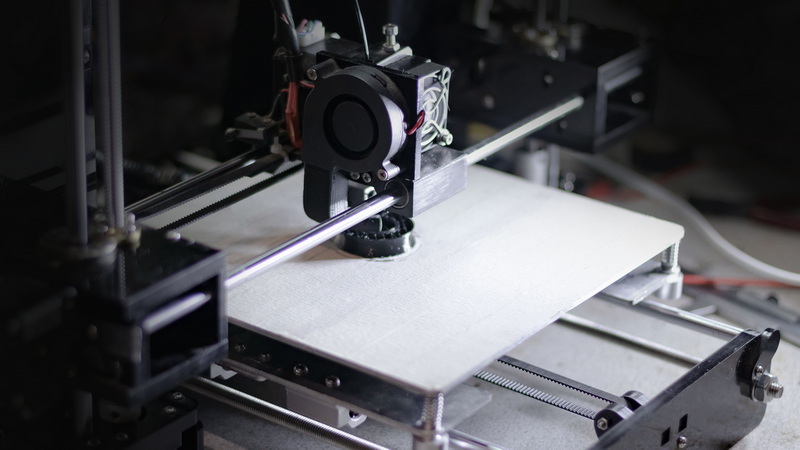

>> 3D Printing

● FAQ

>> 1. What is the most commonly used material for rapid prototyping?

>> 2. Can metal materials be used for rapid prototyping?

>> 3. How do I choose the right material for my prototype?

>> 4. Are there eco-friendly materials available for rapid prototyping?

>> 5. What is the difference between functional and visual prototypes in terms of material selection?

Rapid prototyping has revolutionized the way products are developed, tested, and brought to market. By enabling designers and engineers to quickly create physical models of their ideas, rapid prototyping accelerates innovation and reduces time-to-market. One of the most critical decisions in this process is selecting the right material. The choice of material impacts not only the performance and appearance of the prototype but also the speed, cost, and feasibility of manufacturing. This comprehensive guide explores the best materials for rapid prototyping, examining their properties, applications, and suitability for various prototyping methods.

Rapid prototyping refers to a group of techniques used to quickly fabricate a scale model or part using three-dimensional computer-aided design (CAD) data. This process allows for fast iterations, enabling designers to test form, fit, and function before committing to full-scale production.

- Speed: Accelerates product development cycles.

- Cost-Effectiveness: Reduces the need for expensive tooling.

- Flexibility: Allows for easy design modifications.

- Risk Reduction: Identifies design flaws early.

Rapid prototyping is not just about speed; it is a strategic approach that integrates design, engineering, and manufacturing to ensure that the final product meets all specifications and customer expectations. The choice of materials plays a pivotal role in this integration, influencing everything from prototype durability to production scalability.

Choosing the right material for rapid prototyping is crucial. Consider the following factors:

- Mechanical Properties: Strength, flexibility, hardness, and durability. Some prototypes require materials that can withstand mechanical stress, while others only need to represent shape and form.

- Surface Finish: Smoothness, gloss, and texture. Visual prototypes often demand high-quality surface finishes to simulate the final product's look.

- Thermal Properties: Heat resistance and stability. Prototypes exposed to heat during testing or use must be made from materials that maintain integrity under temperature changes.

- Chemical Resistance: Suitability for specific environments. For example, prototypes used in chemical processing or medical applications may require materials resistant to solvents or bodily fluids.

- Cost: Material and processing expenses. Budget constraints often influence material choice, especially in early design phases.

- Machinability: Ease of processing with available technologies. Some materials are easier to machine or print, impacting lead times and precision.

- End-Use Application: Functional or visual prototype requirements. Knowing whether the prototype is for form, fit, or function guides material decisions.

Understanding these factors helps manufacturers and designers align material properties with project goals, ensuring that prototypes are both effective and economical.

Plastics dominate the rapid prototyping landscape because of their adaptability, affordability, and broad range of properties. They are ideal for both visual and functional prototypes.

ABS is a thermoplastic known for its toughness and impact resistance. It is widely used in automotive parts, consumer products, and functional prototypes. ABS can be easily machined or 3D printed, offering a good balance of strength and flexibility. Its slightly glossy finish also makes it suitable for visual models.

PLA is a biodegradable plastic derived from renewable resources like corn starch. It is popular for concept models and educational prototypes due to its ease of printing and minimal warping. While PLA is less durable than ABS, its environmental friendliness and ease of use make it a favorite for early-stage prototyping.

Nylon is valued for its high strength, flexibility, and wear resistance. It is commonly used for mechanical parts such as gears, hinges, and functional prototypes that require durability. Nylon's ability to absorb impact and resist abrasion makes it suitable for prototypes subjected to mechanical testing.

Polycarbonate offers excellent impact resistance, transparency, and heat resistance. It is often chosen for prototypes requiring toughness and clarity, such as electrical housings and transparent components. PC can withstand higher temperatures than ABS or PLA, which is beneficial for functional testing.

TPU is a flexible, rubber-like material known for its abrasion resistance and elasticity. It is ideal for prototypes like seals, gaskets, and flexible connectors. TPU's flexibility allows designers to test parts that need to bend or stretch without breaking.

Metal prototyping is essential for parts requiring high strength, durability, or specific thermal properties. Advances in additive manufacturing and CNC machining have made metal prototypes more accessible and cost-effective.

Aluminum is lightweight, strong, and has excellent machinability. It is widely used in aerospace, automotive, and structural components. Aluminum prototypes provide a realistic feel and performance, making them ideal for functional testing and validation.

Stainless steel offers corrosion resistance, strength, and durability. It is commonly used in medical devices, tools, and mechanical parts that require longevity and exposure to harsh environments. Stainless steel prototypes are often produced via CNC machining or metal 3D printing.

Titanium is prized for its high strength-to-weight ratio and biocompatibility. It is used in aerospace, medical implants, and high-performance applications. Although more expensive, titanium prototypes provide unmatched performance in critical applications.

Brass and copper are known for their electrical conductivity, machinability, and corrosion resistance. They are used in electrical components and decorative parts. These metals are often chosen for prototypes requiring conductivity or aesthetic appeal.

Composites combine two or more materials to achieve enhanced properties, such as increased strength or reduced weight.

Carbon fiber composites are extremely strong and lightweight. They are widely used in automotive, aerospace, and sporting goods industries. Prototypes made from carbon fiber composites can simulate the final product's mechanical performance while reducing weight.

Glass-filled nylon contains glass fibers to improve strength and rigidity compared to standard nylon. It is suitable for structural parts and industrial components where additional stiffness is required.

Silicone is flexible, heat-resistant, and biocompatible, making it ideal for medical devices, seals, and molds. It can replicate soft tissue or flexible parts in prototypes, providing realistic tactile feedback.

Wax is easy to shape and has a low melting point, making it useful for investment casting and jewelry prototyping. Wax models can be quickly produced and used as patterns for metal casting.

3D printing, or additive manufacturing, offers a wide range of material options, allowing for rapid iteration and customization.

- PLA: Best for concept models and educational prototypes due to ease of printing and biodegradability.

- ABS: Suitable for functional prototypes requiring durability and impact resistance.

- Nylon: Ideal for mechanical parts needing flexibility and wear resistance.

- Resin: Provides high detail and smooth finish, perfect for visual prototypes and dental models.

- Metal Powders: Used in metal 3D printing to produce strong, heat-resistant parts for aerospace and end-use applications.

3D printing materials vary widely in cost and performance, so selecting the right one depends on prototype requirements and budget.

CNC machining is ideal for producing high-precision prototypes from real engineering materials, offering excellent surface finish and mechanical properties.

- Aluminum: Lightweight and machinable, great for structural components.

- Stainless Steel: Strong and corrosion-resistant, used in medical and mechanical parts.

- Brass: Conductive and easy to machine, suitable for electrical and decorative parts.

- Engineering Plastics: Durable and versatile for functional prototypes.

CNC machining allows for rapid turnaround and high accuracy, making it a preferred method for functional prototypes.

Sheet metal prototyping uses materials like aluminum, steel, and copper to create enclosures, brackets, and structural parts.

- Aluminum: Lightweight and corrosion-resistant, ideal for enclosures and brackets.

- Stainless Steel: Strong and durable, used for structural parts.

- Copper: Conductive, suitable for electrical enclosures.

Sheet metal prototypes are often used to validate form and fit in metal parts before mass production.

Injection molding prototypes closely mimic mass-produced parts and are useful for testing production processes and part performance.

- ABS: Durable and versatile, commonly used for consumer products.

- Polypropylene: Flexible and chemical resistant, used in packaging and automotive.

- Polycarbonate: Transparent and tough, suitable for optical parts.

Injection molding prototypes require tooling but offer excellent material properties and surface finish for final validation.

Choosing the best materials for rapid prototyping is essential to achieving the desired functionality, appearance, and manufacturability of your prototypes. Each material offers unique benefits, whether you need the flexibility of plastics, the strength of metals, or the advanced properties of composites. By understanding the requirements of your project and the capabilities of various prototyping methods, you can select the optimal material to bring your ideas to life efficiently and effectively. Rapid prototyping continues to empower innovation, and the right material choice is at the heart of every successful prototype.

The most commonly used material is plastic, particularly PLA and ABS, due to their ease of processing, affordability, and versatility for both concept and functional prototypes.

Yes, metals such as aluminum, stainless steel, and titanium are widely used in rapid prototyping, especially for parts requiring high strength, durability, or specific thermal properties.

Consider factors such as mechanical requirements, surface finish, end-use application, and cost. Evaluate the capabilities of your chosen prototyping method and consult with your manufacturing partner for recommendations.

Yes, materials like PLA are biodegradable and derived from renewable resources, making them an eco-friendly choice for rapid prototyping.

Functional prototypes require materials that mimic the mechanical properties of the final product, such as strength and durability. Visual prototypes focus on appearance and may use materials optimized for surface finish and detail.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam