Views: 222 Author: Amanda Publish Time: 2025-08-31 Origin: Site

Content Menu

● Core Components of CNC Lathe Turning Machines

● Different Types of CNC Lathe Turning Machines

>> 3-Axis and Multi-Axis CNC Lathes

>> Multi-Turret and Dual-Spindle CNC Lathes

>> Swiss CNC Lathes (Sliding Headstock Lathes)

● How CNC Lathe Turning Machines Work

● Applications and Benefits of CNC Lathe Turning

● FAQ

>> 1. What is the difference between a CNC lathe and a CNC turning center?

>> 2. How does a dual-spindle CNC lathe increase productivity?

>> 3. Why choose a Swiss CNC lathe over a standard lathe?

>> 4. What industries benefit most from CNC lathe turning machines?

>> 5. What materials can CNC lathe turning machines work with?

CNC Lathe Turning machines are a cornerstone of modern manufacturing, offering precision, efficiency, and versatility across industries. These sophisticated tools automate the shaping of metal and other materials by rotating the workpiece against cutting tools under computer numerical control (CNC). Understanding the multiple types of CNC lathe turning machines, their components, and applications can empower manufacturers, engineers, and enthusiasts to select the right machine for their unique needs. This article provides a comprehensive overview of the various CNC lathe turning machines, shedding light on their features, operational principles, and industrial use.

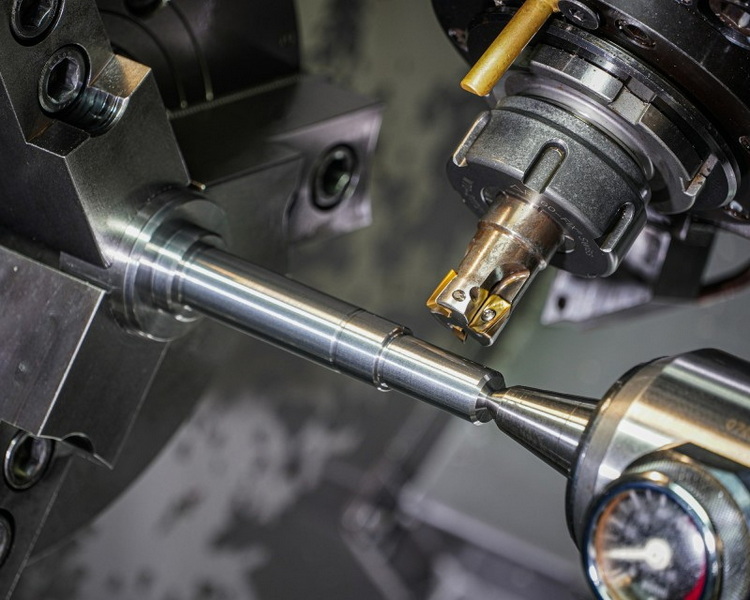

CNC lathe turning is a manufacturing process in which a workpiece is rotated on a spindle while cutting tools precisely remove material to create cylindrical, conical, or complex shapes. CNC refers to the computerized control system that directs the movements of the tools and spindle to achieve high repeatability and accuracy. The process excels in producing symmetrical parts such as shafts, screws, pulleys, and other rotary components.[2][5]

The machine typically operates along two primary axes:

- Z-axis: Movement of the cutting tool along the length of the workpiece (spindle axis).

- X-axis: Movement perpendicular to the spindle, controlling cutting depth.

More advanced CNC lathes may include additional axes, enabling multi-directional machining.[3]

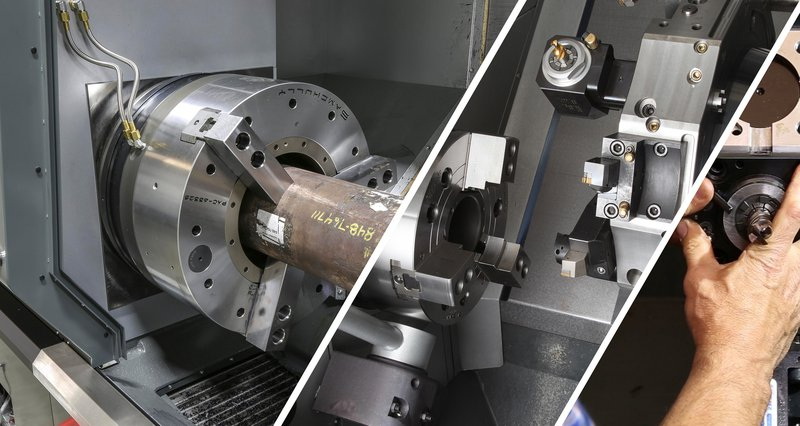

A CNC lathe turning machine consists of several essential parts working in synergy to automate precise shaping:

- Machine Bed: The sturdy base where all components are mounted, ensuring stability during machining.

- Headstock: Houses the main spindle and motor, providing the rotational force to the workpiece.

- Main Spindle: The rotating axis that clamps and spins the workpiece.

- Chuck: Attached to the spindle, it securely holds the workpiece in place.

- Tailstock: Positioned opposite the headstock, offering additional support for long workpieces.

- Tool Turret: A key component that holds multiple cutting tools, which can be indexed automatically for rapid tool changes.

- Guideways: Allow smooth movement of tool carriage and turret along the X and Z axes.

- Sub-Spindle (Optional): Enables secondary operations on the backside of the workpiece without manual repositioning.

Together, these components facilitate efficient and accurate turning, drilling, facing, and milling operations.[1][4]

The most fundamental CNC lathe turning machine operates on two axes: Z and X. These machines are suitable for basic turning operations, primarily focusing on external diameters. They are common for simple parts requiring cylindrical shaping, facing, and taper turning. Their straightforward design makes them accessible and cost-effective for standard machining needs.[5][1]

Modern CNC lathes extend functionality beyond two axes. The addition of the Y-axis and C-axis enables even more complex machining capabilities:

- 3-Axis CNC Lathe: Incorporates live tooling (rotating cutting tools) that allows milling, drilling, and tapping operations in addition to turning. This axis greatly expands machining capabilities within a single setup.

- 4-Axis and 5-Axis CNC Lathes: Include more sophisticated tool movements and orientations, such as rotary tables and additional sub-spindle control. These lathes can machine intricate geometries, slots, and flat surfaces alongside traditional turning.[1][3]

Horizontal CNC lathes position the spindle horizontally. They are suited for high-volume production of small to medium-sized parts. Chips fall downward and often onto conveyors for easy removal, enhancing cleanliness and operational efficiency. These machines are versatile and widely used in automotive, aerospace, and general manufacturing.[2]

Vertical CNC lathes orient the spindle vertically to turn large, heavy, or awkwardly shaped parts such as turbine blades, rings, and heavy flanges. Gravity assists in holding the workpiece on the rotating plate, which helps stabilize and reduce tool wear. Vertical lathes are indispensable for batch and heavy-duty machining.[3][2]

These advanced machines feature two tool turrets for simultaneous tool changes and a secondary spindle (sub-spindle) for machining both ends of a part without repositioning, dramatically cutting cycle times. Dual-spindle lathes are ideal for high-precision, high-throughput environments. The ability to perform multiple operations in one setup improves consistency and reduces handling errors.[1][3]

Swiss-type CNC lathes excel in producing small, intricate parts such as medical devices, watch components, and miniature screws. The bar stock is fed through a guide bushing close to the cutting tools, which stabilizes the stock and allows for tight tolerances and minimal deflection. These machines often combine multiple axes and live tooling, delivering rapid cycle times and precision.[3][1]

The CNC lathe turning process begins with designing the part using CAD (Computer-Aided Design) software. The design is converted into CNC code (G-code), programmed with precise instructions for tool paths, spindle speed, feed rates, and cuts.

Once the raw material (usually cylindrical stock) is loaded into the chuck, the machine's spindle rotates it at controlled speeds. The tool turret indexes the cutting tools into position, guided by CNC instructions to move along the X and Z axes to shape the workpiece. The machine may perform multiple passes to achieve the final geometry, including drilling, boring, knurling, and threading. Feedback systems ensure accuracy and compensate for tool wear.[4][6]

The automation provided by CNC results in consistent parts with minimal human error, high speed, and the ability to produce complex shapes that were difficult or impossible with manual lathes.

CNC lathe turning machines play critical roles in industries such as automotive, aerospace, electronics, medical devices, and general manufacturing where precision and repeatability are paramount. Some benefits include:

- High Precision: CNC control ensures tight tolerances and uniform parts.

- Efficiency: Automated tool changes and multi-axis capabilities reduce cycle times.

- Versatility: Machines can handle diverse materials and complex geometries.

- Reduced Labor Costs: Less manual intervention and fewer mistakes.

- Flexibility: Quick reprogramming allows for rapid prototyping and small batch production.[7][3]

CNC lathe turning machines are indispensable in modern manufacturing, with various types catering to different machining needs—from simple cylindrical turning to multi-axis complex part production. Understanding the distinctions between standard 2-axis lathes, multi-axis turning centers, horizontal and vertical configurations, multi-turret setups, and Swiss-type lathes enables manufacturers to select the optimal machine for their operations. The integration of CNC control brings unmatched precision, speed, and repeatability to turning processes, making these machines essential for industries demanding high-quality, efficient production.

A CNC lathe primarily focuses on turning operations with 2-axis control, while a CNC turning center offers multi-axis capabilities, live tooling, and more complex machining functions such as milling and drilling in addition to turning.[1][3]

Dual-spindle CNC lathes can machine both ends of a workpiece simultaneously or sequentially without manual repositioning, reducing cycle times and increasing throughput, especially in high-volume production.[1]

Swiss CNC lathes are designed for high-precision machining of small, slender parts. The guide bushing supports the part close to the cutting tool, minimizing deflection and enabling tighter tolerances than standard lathes.[3][1]

Automotive, aerospace, electronics, medical device manufacturing, and general machinery industries benefit greatly due to the machines' accuracy, repeatability, and ability to produce complex parts efficiently.[7][3]

CNC lathes can machine a wide range of materials, including metals (steel, aluminum, brass, titanium), plastics, composites, and sometimes even wood, depending on tooling and machine configuration.[6]

[1](https://www.gz-supplies.com/news/the-ultimate-guide-to-cnc-lathe-machining-and-turning-centers/)

[2](https://eurometalsolutions.com/blog/complete-guide-to-cnc-machining-everything-you-need-to-know/)

[3](https://kingsburyuk.com/cnc-turning-guide/)

[4](https://at-machining.com/cnc-lathe-parts/)

[5](https://www.cnccookbook.com/understand-cnc-machine-types-a-comprehensive-guide/)

[6](https://kenworthengineering.co.uk/news-and-insights/cnc-turning-the-complete-guide/)

[7](https://www.pt-engineers.co.uk/cnc-lathe-machining-a-quick-guide/)

[8](https://tmc-technologies.com/cnc-lathe-programming/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal