Views: 222 Author: Amanda Publish Time: 2025-07-06 Origin: Site

Content Menu

>> Technologies Used in Rapid Prototyping

● Leading Rapid Prototyping Manufacturers in Canada

>> 1. Sculpteo

>> 2. Proto3000

● Advanced Rapid Prototyping Techniques and Trends

>> Multi-Material and Multi-Color 3D Printing

>> High-Temperature and High-Strength Materials

>> Integration of AI and Automation

>> Sustainability in Prototyping

● Benefits of Working with Canadian Rapid Prototyping Manufacturers

● OEM Rapid Prototyping: A Strategic Advantage

>> 1. What industries benefit most from rapid prototyping manufacturers?

>> 2. How does 3D printing compare to CNC machining in prototyping?

>> 3. Can rapid prototyping be used for low-volume production?

>> 4. What materials are commonly used in rapid prototyping?

>> 5. How do rapid prototyping services support OEM product development?

In today's fast-evolving manufacturing landscape, rapid prototyping manufacturers play a pivotal role in accelerating product development cycles. For brands, wholesalers, and producers seeking OEM services, Canada offers a robust ecosystem of innovative rapid prototyping suppliers. These companies specialize in cutting-edge technologies such as 3D printing, CNC machining, sheet metal fabrication, and vacuum casting, enabling businesses to transform ideas into physical prototypes swiftly and accurately.

This article explores the top rapid prototyping manufacturers in Canada, highlighting their capabilities, technologies, and how they serve diverse industries. We also discuss the benefits of rapid prototyping, including cost savings, faster time-to-market, and enhanced product validation.

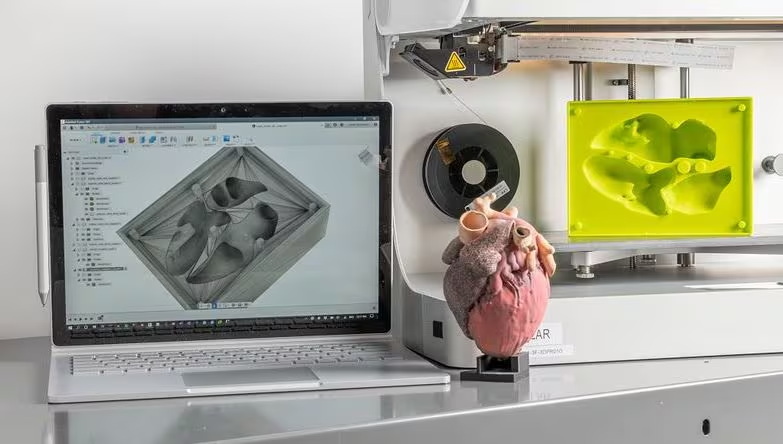

Rapid prototyping is a collection of techniques used to quickly fabricate a scale model or functional prototype of a physical part or assembly using three-dimensional computer-aided design (CAD) data. It enables designers and engineers to test form, fit, and function early in the product development process, minimizing costly errors and accelerating the path to production.

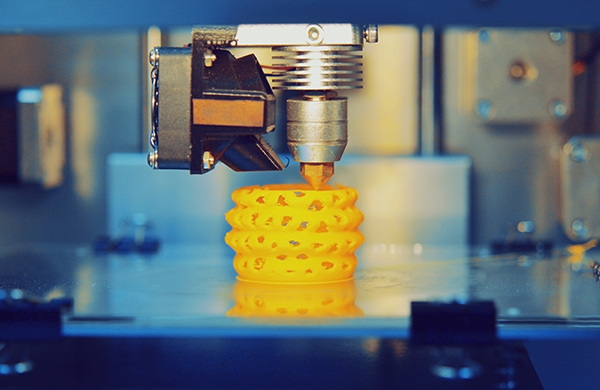

- 3D Printing (Additive Manufacturing): Builds parts layer by layer using materials like plastics, resins, and metals.

- CNC Machining: Subtractive manufacturing that carves prototypes from solid blocks with high precision.

- Vacuum Casting: Produces small batches of parts with excellent surface finish and mechanical properties.

- Sheet Metal Fabrication: Used for creating prototypes with metal sheets through cutting, bending, and assembling.

- Injection Molding: For producing functional prototypes and low-volume production parts.

Sculpteo is a global rapid prototyping leader with a strong Canadian presence. Their platform offers a wide range of technologies including 3D printing, CNC machining, and vacuum casting. Sculpteo's user-friendly online interface allows clients to upload designs and receive high-quality prototypes quickly. Their ability to handle complex geometries and diverse materials makes them a versatile partner for many industries.

Proto3000 is renowned for its comprehensive rapid prototyping services, including additive manufacturing and CNC machining. Their engineering team supports customers throughout the design-to-production process, ensuring prototypes meet exact specifications. Proto3000's fast turnaround and quality have made them a trusted partner across industries such as automotive, aerospace, and consumer products.

Javelin Technologies excels in delivering customized rapid prototyping solutions using 3D printing, CNC machining, and sheet metal fabrication. Their experienced team focuses on innovation and detail to exceed client expectations, making them a preferred choice for complex prototyping projects. They also provide design consulting to optimize prototypes for manufacturability.

RapidDirect offers an extensive portfolio of rapid prototyping services such as 3D printing, CNC machining, and injection molding. Their strong supplier network across Canada ensures reliable and efficient delivery, supporting businesses from startups to established manufacturers. Their online quoting system streamlines the ordering process, making rapid prototyping accessible and convenient.

Based in Toronto, Custom Prototypes Inc. has over 20 years of experience specializing in rapid prototyping and short-run manufacturing. Their advanced facilities include 3D printing, CNC machining, plastic vacuum forming, and carbon fiber autoclaves. They serve diverse markets including consumer products, medical devices, and motion pictures. Their expertise in composite materials adds unique value for specialized prototyping needs.

Axis Prototypes is a pioneer in Canadian additive manufacturing with expertise in SLA, SLS, DMLS, FDM, and PolyJet 3D printing. Their team provides design consultations and uses a wide variety of materials to create precise and functional prototypes. They emphasize quality control and post-processing to ensure prototypes meet demanding standards.

ProtoDev Canada offers end-to-end prototyping services from 2D/3D modeling to custom software and PCB design. With over two decades of experience, they help accelerate product development and market readiness. Their multidisciplinary approach integrates electronics and mechanical prototyping, ideal for complex product designs.

As technology evolves, rapid prototyping manufacturers in Canada are adopting advanced methods to meet growing industry demands. Some of these trends include:

Modern 3D printers can now print with multiple materials and colors simultaneously, enabling prototypes that better simulate final products. This capability is crucial for consumer goods, medical devices, and automotive components where aesthetics and material properties matter.

The development of new polymers and metal alloys allows prototypes to withstand rigorous testing conditions. Materials like PEEK, Ultem, and titanium alloys are increasingly used for functional prototypes that require high durability and heat resistance.

Manufacturers are incorporating artificial intelligence and automation into prototyping workflows to optimize design, reduce errors, and speed up production. AI-driven design tools help generate optimized structures, while automated post-processing improves consistency and quality.

Combining additive and subtractive manufacturing techniques provides the best of both worlds—complex geometries from 3D printing and fine surface finishes from CNC machining. Hybrid approaches are gaining traction for producing high-precision prototypes with superior mechanical properties.

Canadian rapid prototyping companies are also focusing on eco-friendly materials and processes. Biodegradable polymers, recycled materials, and energy-efficient machines reduce the environmental footprint of prototyping activities, aligning with global sustainability goals.

- Faster Time-to-Market: Rapid prototyping compresses development cycles, enabling quicker product launches.

- Cost Efficiency: Early detection of design flaws reduces expensive rework and tooling costs.

- High Precision: Advanced technologies ensure prototypes meet tight tolerances and complex geometries.

- Customization: Flexible manufacturing processes allow for tailored prototypes to meet unique requirements.

- Collaboration: Prototyping facilitates better communication between design, engineering, and production teams.

- Access to Expertise: Canadian manufacturers often provide design consulting and engineering support, enhancing prototype quality.

- Diverse Material Options: From plastics to metals and composites, a wide range of materials are available to suit different applications.

- Local Support and Faster Shipping: Working with Canadian suppliers reduces lead times and simplifies logistics for North American clients.

OEMs increasingly rely on rapid prototyping to optimize product development. By leveraging 3D printing and CNC machining, OEMs can iterate designs quickly, test functionality, and validate products before committing to high-volume production. This approach reduces lead times and enhances product quality, critical in competitive markets such as automotive, healthcare, and consumer electronics.

Rapid prototyping also supports risk mitigation by allowing OEMs to identify potential manufacturing challenges early. This proactive approach helps avoid costly delays and ensures smoother transitions to mass production. Furthermore, rapid prototyping enables OEMs to customize products for different markets or customer segments without significant tooling investments.

Canada's rapid prototyping manufacturers stand out for their technological expertise, diverse service offerings, and commitment to quality. From 3D printing to CNC machining and vacuum casting, these companies empower businesses to innovate faster, reduce costs, and bring superior products to market efficiently. For OEMs and brands seeking reliable partners, Canadian rapid prototyping suppliers provide a strategic edge in today's dynamic manufacturing environment.

By embracing advanced technologies, sustainability, and customer-centric approaches, Canadian rapid prototyping manufacturers continue to drive innovation across industries. Whether you are developing a new consumer product, medical device, or industrial component, partnering with a top Canadian rapid prototyping manufacturer can transform your ideas into reality with speed and precision.

Rapid prototyping serves industries such as automotive, aerospace, healthcare, consumer electronics, and industrial design, where fast iteration and precise testing are crucial. It is also valuable in education, research, and product development startups.

3D printing excels at producing complex geometries and quick iterations with minimal setup, while CNC machining offers superior surface finish and material strength for functional prototypes. Often, a combination of both is used to leverage their respective strengths.

Yes, many rapid prototyping technologies like vacuum casting and 3D printed tooling enable low-volume production runs before full-scale manufacturing. This flexibility helps companies test markets and customize products without large upfront costs.

Materials range from various plastics (ABS, PLA, nylon) and resins to metals like aluminum, stainless steel, and titanium, depending on the prototyping technology and application. Composite materials and bio-based polymers are also gaining popularity.

They reduce development time and costs by enabling early design validation, functional testing, and iterative improvements, accelerating the path from concept to market-ready products. Prototyping also helps OEMs identify manufacturing challenges and optimize designs for production.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal