Views: 222 Author: Amanda Publish Time: 2025-08-02 Origin: Site

Content Menu

● The Evolution of CNC Milling in Korea

● Advantages of Choosing Korean CNC Milling Services Manufacturers and Suppliers

>> 1. Advanced Technology and R&D

>> 2. Rigorous Quality Control Systems

>> 4. Cost Efficiency and Operational Scalability

>> 5. Global Logistics and Customer Support

● Leading CNC Milling Services Manufacturers and Suppliers in Korea

>> Hyundai Wia

>> Other Notable CNC Milling Services Manufacturers and Suppliers in Korea

● How to Choose Your CNC Milling Supplier in Korea

● FAQ

>> 1. What industries benefit most from Korean CNC milling services manufacturers and suppliers?

>> 2. How do Korean CNC milling services manufacturers ensure quality?

>> 3. Can suppliers in Korea handle rapid prototyping as well as mass production?

>> 4. Are Korean CNC milling services manufacturers and suppliers competitive internationally?

>> 5. How can I find the best Korean CNC milling services manufacturer or supplier for my needs?

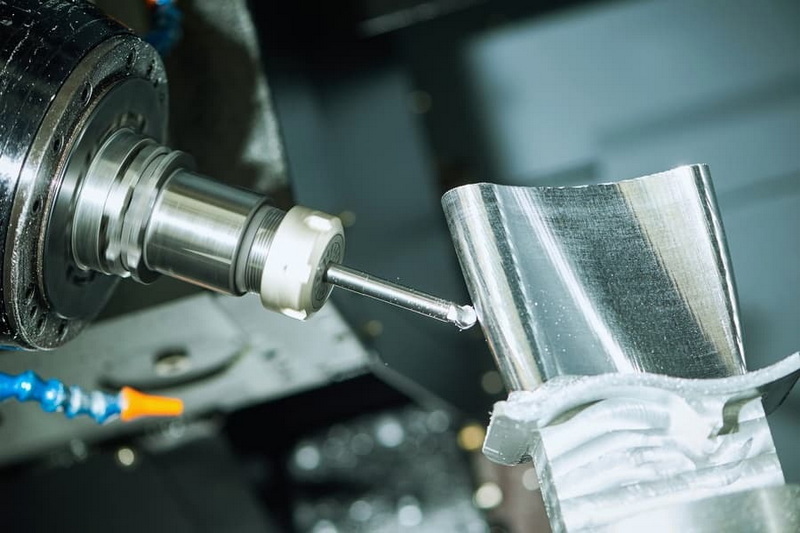

South Korea has solidified its position as a leading force in advanced manufacturing within Asia. The country's CNC milling services manufacturers and suppliers hold a prestigious global reputation for precision, innovation, and superior reliability. Serving industries ranging from automotive and aerospace to electronics, shipbuilding, and medical devices, Korea's manufacturing sector has become a critical hub for OEMs worldwide, powering technological advancements and maintaining rigorous quality standards.

Blending decades of craftsmanship with cutting-edge technology, Korean CNC milling companies excel in producing complex, high-tolerance parts essential to future-ready industries. This article delves into the evolution of CNC milling in Korea, highlights the key advantages offered by Korean suppliers, profiles leading manufacturers, showcases visual insights into their technology and production environments, and guides readers on selecting the best partners in Korea.

Korea's transformation from a war-devastated state to a global manufacturing titan is rooted in strategic industrial policy and sustained innovation efforts. Starting in the late 20th century, Korean manufacturers embraced Computer Numerical Control (CNC) technology, shifting from manual machining to automated, precision-driven operations.

Today, Korean CNC milling services manufacturers and suppliers operate at the vanguard of Industry 4.0, characterized by:

- Multi-axis machining centers enabling complex part geometries

- Automated tool changers reducing downtime and increasing throughput

- Robotic material handling systems for consistency and safety

- IoT-enabled monitoring systems providing real-time process data

- Fully integrated smart factories optimizing workflows and reducing waste

This evolution allows suppliers to meet stringent quality demands and supply massive volumes of parts with impeccable precision, supporting cutting-edge sectors including electric vehicles, aerospace systems, semiconductor manufacturing, and medical instrumentation.

Korea's commitment to research and development ensures manufacturers are equipped with the latest CNC machines — including 5-axis and multitasking centers — and leverage software advancements in CAD/CAM, automated process control, and quality inspection.

Korean manufacturers uphold strict ISO-certified quality management systems. They employ high-precision metrology equipment including CMMs (Coordinate Measuring Machines), laser scanners, and vision systems to verify dimensions and surface finish, guaranteeing parts meet or exceed global standards.

Whether it's rapid prototyping, low-volume custom jobs, or full-scale mass production runs, Korean CNC milling services manufacturers and suppliers offer scalable and flexible solutions. They accommodate a variety of materials such as aluminum, titanium, stainless steel, and exotic alloys.

Competitive labor costs combined with technologically advanced machinery enable Korean suppliers to offer cost-effective CNC milling services. The option to scale production up or down without compromising quality appeals to both niche innovators and large multinational OEMs.

Leading Korean manufacturers provide comprehensive international support networks. They facilitate fast shipping, spare parts delivery, and technical assistance across different time zones, reducing lead times and enhancing client satisfaction.

Established in 1976, Hyundai Wia stands as a titan in global CNC solutions. They offer a broad spectrum of milling machinery including vertical, horizontal, and 5-axis machining centers, together with advanced CNC turning centers.

- Known for exceptional rigidity and accuracy

- Focuses on smart factory integration and productivity improvements

- Holds certifications such as ISO 9001, ISO 14001, CE, UL, and CSA

Starting in 1976 and with operations extending to China and the USA, Doosan Machine Tools is recognized for reliability and diverse equipment lines.

- Product range includes CNC lathes, machining centers, gantry mills, and multitasking machines

- Serves aerospace, automotive, energy, and medical industries

- ISO 9001, ISO 14001, and CE certified

Dating back to 1945, Hwacheon is one of Korea's oldest and most comprehensive manufacturers of CNC milling equipment. They produce their own castings, emphasizing complete in-house control.

- Specializes in horizontal, vertical, and 5-axis machining centers as well as turning centers

- Known for customization capability and manual scraping expertise for precision

- Maintains ISO 9001, ISO 14001, and CE certifications

Operating since 1953, Hanwha blends CNC machining technology with robotics to provide fast, flexible automation.

- Offers CNC lathes, machining centers, multi-tasking machines, and industrial robots

- Focused on electronics manufacturing and automated assembly lines

- Certified ISO 9001, ISO 14001, and CE

Originally Samsung Machine Tools, SMEC provides state-of-the-art machining technologies optimized for smart factory environments.

- Supplies integrated machining centers and multi-axis lathes

- Employs IoT and robotics for enhanced automation and manufacturing intelligence

- Holds ISO 9001, ISO 14001, and CE certifications

Specializing in heavy-duty applications, Hankook manufactures vertical turning lathes, complex milling-turning centers, and horizontal lathes.

- Markets primarily to shipbuilding, steel, and wind energy sectors

- ISO 9001, ISO 14001, CE certified

With over six decades' experience, HNK is synonymous with large-format CNC machinery including planomillers and boring mills.

- Provides robust double-column machining centers with global export and service networks

Established in 1950, Namsun delivers five-axis machining centers and versatile CNC milling machines.

- Emphasizes tailor-made solutions for unique production challenges

Ameco focuses on eco-friendly, efficient machining centers and peripheral automation, including chip conveyors and hydraulic systems.

- Samsung Machine Tools: Offers a wide array of CNC lathes, milling and drilling solutions.

- Korea Machine Tools: Specialists in machining centers suited for both batch and mass production.

- Mori Seiki Korea: Premium CNC equipment supplier known for precision.

- WIA Corporation: Renowned for precision lathes and grinding machines.

- Kaenn Tech: Provides advanced automation and customized production solutions.

Navigating the selection of a CNC milling supplier in Korea requires systematic evaluation:

1. Define Your Product Needs

Clarify material types, size, tolerance levels, surface finishes, and production volume.

2. Assess Technology Capabilities

Ensure the supplier uses machines that handle required axes, tooling options, and automation like robotic loading or secondary processing.

3. Verify Certifications and Compliance

Check for ISO standards, industry-specific certifications, and adherence to international quality norms.

4. Examine Lead Times and Flexibility

Confirm ability to support prototyping, variable batch sizes, and scalability for growing demands.

5. Consider After-Sales and Global Support

Evaluate availability of technical assistance, spare parts, and service response times globally.

6. Review Pricing and Contract Terms

Look for transparent cost structures, currency accommodation, and clear payment/warranty terms.

Korea's CNC milling services manufacturers and suppliers maintain their prominence by harmonizing rich industrial heritage with cutting-edge technological innovation. Their ability to deliver precise, scalable, and cost-effective solutions fuel global industries that demand stringent standards and seamless production workflows.

From rapid prototyping startups to large OEMs, partnering with Korean CNC specialists offers access to comprehensive manufacturing capabilities backed by robust quality controls, advanced automation, and global service networks. Korea remains a top destination for those seeking world-class CNC milling services that combine efficiency, accuracy, and responsiveness.

Key beneficiaries include automotive, aerospace, electronics, shipbuilding, medical device, and industrial machinery industries. Korean suppliers' precision, technology adoption, and flexible volume capacity make them ideal partners across these fields.

They implement multi-stage inspection processes certified under ISO 9001/14001 standards, utilize advanced metrology equipment, and continuously monitor production parameters with digital monitoring systems to deliver consistent, high-quality parts.

Yes. Korean CNC manufacturers are adept at offering flexible solutions ranging from quick-turn prototyping and batch manufacturing to high-volume production using highly automated facilities.

Korean suppliers compete strongly with global leaders in Japan, Germany, and the US by combining innovation, competitive pricing, excellent service, and adherence to international standards.

Start by outlining your technical specs and volume requirements. Research supplier capabilities, certifications, and customer reviews. Request quotations and sample work, and prioritize those offering robust after-sales support and international logistics.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product