Views: 222 Author: Amanda Publish Time: 2025-08-22 Origin: Site

Content Menu

● Introduction to Quality Assurance in CNC Machining

● Understanding CNC Machining and Its Challenges

>> Common Challenges in CNC Machining Quality

● Key Quality Assurance Strategies in CNC Machining

>> Design and Engineering Review

>> Process Validation and Prototype Testing

>> Machine Calibration and Preventive Maintenance

● Inspection and Measurement Techniques

>> Statistical Process Control (SPC)

● Material Selection and Verification

>> Machining Considerations Based on Material

● Implementing Statistical Process Control (SPC)

● Training and Operator Competence

● Importance of Documentation and Traceability

>> 1. What is the most critical factor in CNC machining quality assurance?

>> 2. How often should CNC machines be calibrated for quality production?

>> 3. Can CNC machining produce parts with zero defects?

>> 4. What role does operator training play in CNC machining quality?

>> 5. How does Statistical Process Control (SPC) improve CNC machining quality?

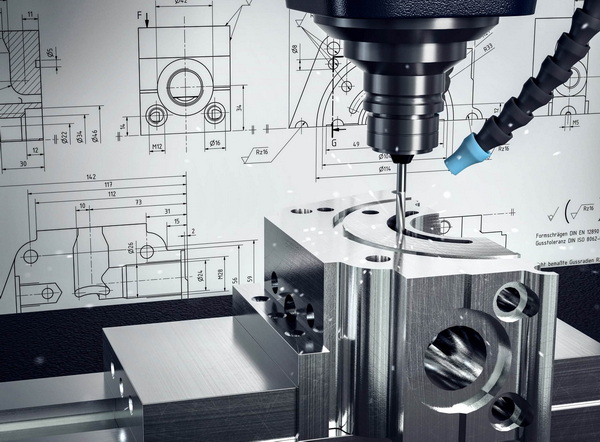

In the fast-evolving manufacturing landscape, CNC machining plays a critical role in delivering precise, high-quality components for various industries—ranging from aerospace and automotive to electronics and medical devices. To meet the stringent demands of international clients, especially for OEM production, ensuring robust quality assurance (QA) in CNC machining production is paramount.

This comprehensive article explores the best practices in quality assurance tailored for CNC machining. It covers every stage from initial design review, process validation to final inspection, combined with practical examples and industry insights. Whether you are a manufacturer, a supplier, or a buyer seeking to optimize CNC machining production quality, this detailed guide will provide actionable solutions and standards to enhance product reliability and client satisfaction.

CNC machining is a highly automated and precise manufacturing process controlled by computer-generated code to remove material from a workpiece. While CNC offers exceptional accuracy and repeatability, quality assurance remains a challenge due to potential errors in programming, tool wear, material inconsistencies, and setup variations.

Quality assurance ideally spans the entire production lifecycle—from prototype design to volume manufacturing—to ensure each part meets defined specifications, tolerances, and surface finishes. In OEM contexts such as those served by Shangchen's rapid prototyping, precision batch production, and 3D printing services, quality assurance procedures must be stringent and meticulously implemented.

CNC (Computer Numerical Control) machining involves using computer-controlled tools such as mills, lathes, and routers to shape raw materials into precise components. The technology enables complex geometries and tight tolerances that are often not achievable with manual machining.

Despite its sophistication, CNC machining faces several challenges that can impact final product quality:

- Dimensional Variation: Thermal expansion of the workpiece or tool deflection during cutting can introduce dimensional deviations.

- Tool Wear and Breakage: Prolonged machining cycles cause gradual tool wear, affecting surface finish and critical dimensions.

- Programming Errors: Incorrect G-code or CAM data results in unintended tool movements causing defects or scrap.

- Material Inconsistency: Variations in raw material properties may alter machining behavior, such as hardness irregularities or internal stresses.

- Setup and Fixturing Issues: Improper workholding can cause part displacement or vibration, leading to inaccuracies and compromised surface quality.

- Environmental Influences: Temperature and humidity fluctuations in the machining environment may change machine behavior or workpiece characteristics.

Quality assurance aims to identify, quantify, and mitigate these factors to maintain consistently high-quality outputs.

Effective quality begins during the design phase. Before machining, a thorough review of engineering drawings and CAD models ensures all features are manufacturable within tolerance and that critical inspection points are identified. Simulation using CAD/CAM software can predict tool access issues, potential collisions, and machining time estimates while highlighting difficult-to-machine areas or tight tolerances.

This proactive review minimizes costly revisions, fixes design-for-manufacturability issues early, and streamlines downstream quality control procedures.

Running prototype parts prior to bulk production serves as a process audit, as it validates CNC programming and machining parameters like feed rate, spindle speed, and coolant application. Prototype evaluation often includes detailed inspections using CMM or optical comparators to compare manufactured parts against design intent. Any deviations are addressed by adjusting tool paths or machining processes.

This iterative testing phase reduces production errors, prevents scrap, and ensures consistent quality once mass production begins.

Optimally functioning CNC machines form the backbone of quality assurance. Calibration involves adjusting machine axes to maintain dimensional precision, often based on laser interferometry or ballbar analysis. Manufacturers should implement a routine calibration schedule to detect wear or misalignment early.

Preventive maintenance protocols, such as lubrication, cleaning, and software updates, also promote stable machine performance over time and help avoid unexpected breakdowns or quality lapses.

A robust tool management system tracks tool life, wear, and sharpness to ensure cutting implements perform at their best. Tools approaching end-of-life are flagged and replaced before they cause dimensional drift or surface defects. Accurate tool offset data and tool presetting reduce set-up times and maintain machining accuracy. Integration with digital tool management software supports traceability and process optimization.

Machining accuracy is affected by temperature-induced thermal expansion of both the machine and workpiece. Maintaining controlled environmental conditions—such as consistent temperature and humidity—in the machine shop reduces fluctuations that may impact tolerances. Some advanced shops employ climate-controlled machining cells to minimize such effects, especially for ultra-precision components.

In-process inspection techniques involve measuring critical dimensions during production rather than waiting until the end. Coordinate measuring machines (CMMs), laser scanners, and tactile probes are commonly deployed to scan sample parts or tool positions on the machine itself. This immediate feedback allows operators to halt production and make adjustments before producing defective batches.

Automated on-machine metrology combined with machine tool data monitoring greatly increases control and process transparency.

Final inspection involves comprehensive checks after machining is complete. Dimensional conformity is verified using high-precision instruments, while surface finish is measured using profilometers. Functional testing, such as assembly fit or mechanical performance, may also be included to guarantee customer requirements are met.

Batch reporting mechanisms ensure traceability by linking inspection records with individual parts or production lots.

SPC is a powerful quality methodology utilizing statistical techniques to monitor production parameters and detect variations before they become defects. Establishing control charts based on dimensional data or surface roughness enables operators to distinguish between acceptable common cause variations and serious special causes that need intervention.

Analysing SPC data helps with root cause investigations, continual process improvements, and reducing scrap or rework.

Material quality directly impacts CNC machining outcomes. Ensure raw materials meet mechanical, chemical, and physical specifications through supplier audits and certifications. Incoming inspection using chemical analysis techniques, such as spectroscopy, confirms material composition consistency.

Material traceability should be rigorously maintained, linking each batch to raw stock certificates and production records. This practice facilitates problem isolation in case of downstream issues and confirms compliance with standards like ASTM or ISO.

Different alloys, plastics, or composites react differently to cutting forces and heat generation during machining. Selecting the appropriate cutting parameters, tooling materials, and cooling/lubrication strategies specific to the workpiece material enhances surface finish and dimensional control.

SPC shifts quality assurance from reactive inspection to proactive production control. Its key components for CNC machining include:

- Data Collection: Sampling critical dimensions or surface characteristics on individual pieces or sub-assemblies.

- Control Charts: Visual dashboards that plot data over time against statistically derived limits.

- Variation Analysis: Identifying whether data points fall within expected ranges or signal potential process drift.

- Corrective Actions: Prompt machine or process adjustments based on SPC results to reduce variability.

Over time, SPC helps build process stability and capability indices (Cp, Cpk) that quantify how well CNC machining consistently meets specifications.

Human factors play a pivotal role in CNC machining quality assurance. Operators and programmers must receive regular training covering:

- Reading and interpreting technical drawings, GD&T symbols, and tolerance stacks.

- Understanding CNC programming principles and verifying G-code correctness.

- Performing accurate machine setup, including clamping, alignment, and tool calibration.

- Utilizing inspection instruments and applying SPC methods.

- Troubleshooting common machining defects and identifying early signs of tool wear or machine issues.

Empowered personnel lead to faster detection and resolution of quality problems, reducing downtime and scrap rates.

Documenting every aspect of the CNC machining process enables quality control and regulatory compliance. Important records include:

- Raw material certificates and batch numbers.

- CNC program versions and setup sheets.

- Machine calibration logs and maintenance records.

- Tool usage and replacement histories.

- Inspection results and SPC data.

Such traceability supports root cause analysis in case of defects and facilitates continual improvement efforts. It is also vital for meeting industry standards such as ISO 9001, AS9100 (aerospace), and medical device regulations.

Quality assurance in CNC machining production demands a systematic, multi-faceted approach addressing design, process control, inspection, material management, and workforce capabilities. By adopting robust QA best practices such as thorough design review, process validation, real-time inspection, and statistical process control, manufacturers can consistently produce high-precision components that meet stringent quality standards.

Meticulous machine calibration, tool management, environmental control, and detailed documentation reinforce this framework, ensuring product reliability and compliance. Investing in operator training further solidifies process integrity, creating a culture of quality from prototype through to volume production.

For OEM clients and global markets, these layered quality assurance strategies minimize defects, reduce waste, and boost competitiveness—essential for successful CNC machining production operations.

The most critical factor is robust process control supported by real-time inspection to detect and correct deviations early, ensuring dimensional accuracy and surface finish are maintained throughout production.

Calibration frequency depends on machine usage intensity and part tolerances but generally ranges from monthly to quarterly. Daily preliminary checks and routine maintenance complement formal calibration schedules.

While absolute zero defects is an aspirational goal, CNC machining can achieve extremely low defect rates by applying stringent quality assurance protocols, including SPC, in-process inspection, and operator training.

Operator training is essential for understanding programming, setup, inspection, and troubleshooting procedures. Skilled operators help prevent errors, quickly identify issues, and maintain process stability.

SPC uses data-driven analysis to monitor critical process variables, differentiating between normal variations and anomalies. This enables proactive intervention before defects occur, increasing yield and consistency.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal