Views: 222 Author: Amanda Publish Time: 2025-09-04 Origin: Site

Content Menu

● Introduction to CNC Lathe Turning

● Understanding CNC Lathe Technology

>> Key Components of CNC Lathe Machines

>> CNC Lathe Turning Processes

● Advantages of CNC Lathe Turning in Industrial Manufacturing

● Custom CNC Lathe Turning Services

● Applications in Industrial Equipment Components

● Materials Used in CNC Lathe Turning

● Quality Assurance and Precision Controls

● FAQ

>> 1. What materials can be machined with CNC lathe turning?

>> 2. How precise is CNC lathe turning?

>> 3. What industries commonly use CNC lathe turned parts?

>> 4. Can CNC lathe turning be used for both prototype and mass production?

>> 5. What is the difference between CNC turning and CNC milling?

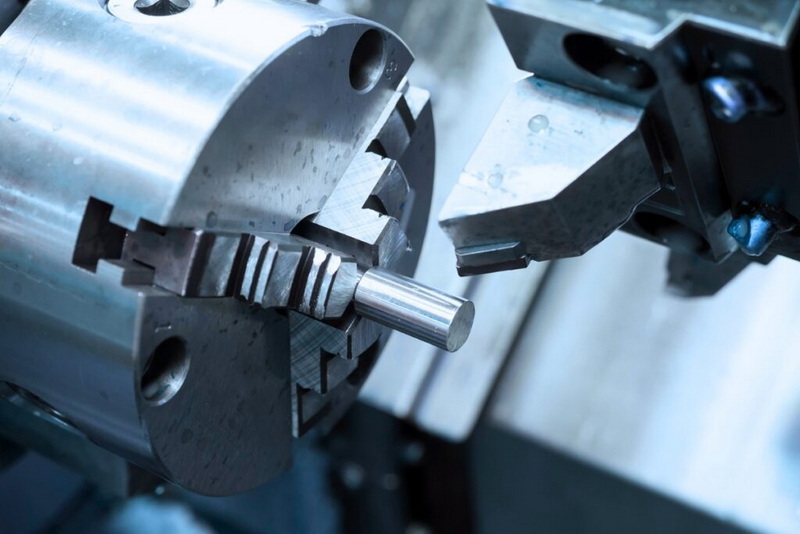

Custom CNC lathe turning is a highly precise and efficient manufacturing process that plays a crucial role in creating industrial equipment components. Using advanced computer numerical control (CNC) technology, lathe machines automate the shaping of metal and other materials by rotating the workpiece while specialized cutting tools remove material. This process produces components with tight tolerances and complex geometries essential for various industrial applications. The integration of precision and automation in CNC lathe turning ensures high repeatability, making it indispensable in modern manufacturing environments.

CNC lathe turning leverages computer programming to control machine operations with exceptional accuracy. The workpiece is securely held in a rotating spindle, and cutting tools are guided by precise movements along multiple axes. This programmable control enables repeatable production of complex parts such as shafts, bushings, couplings, and threaded components often used in machinery.

The control software converts digital designs into motion commands, directing the lathe to execute meticulously planned cuts. This ability to automate complex machining sequences reduces human error and enhances product consistency, which is paramount for industrial equipment components.

- Headstock: Contains the motor and spindle that rotate the workpiece. It is engineered to withstand high forces and vibrations to maintain precision during high-speed operations.

- CNC Lathe Bed: The heavy, vibration-damping base that aligns the machine components to ensure stable and accurate machining over long production cycles.

- Carriage and Cross Slide: These parts hold and move the cutting tool in perpendicular and longitudinal directions for versatile machining operations. The carriage travels along the lathe bed, while the cross slide adjusts the tool's position facing the workpiece.

- Tool Turret: Allows changing multiple cutting tools automatically to perform various machining tasks without restarting the process or manual intervention. This setup enables multiple machining steps like turning, facing, threading, and drilling to be completed in one setup.

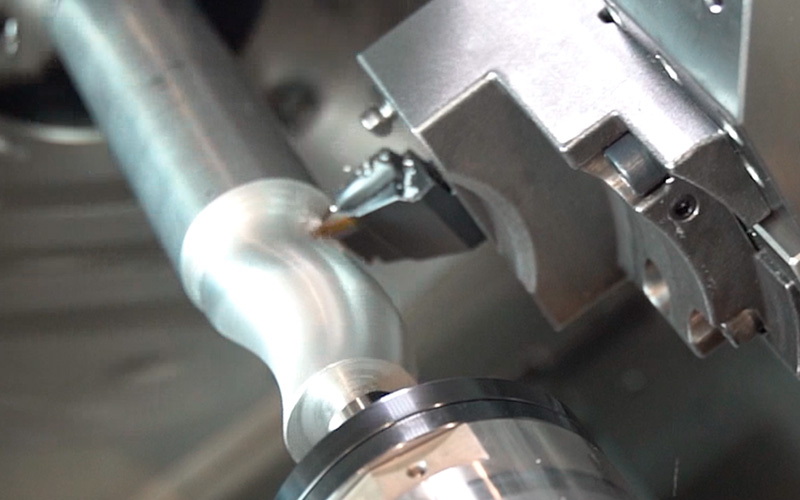

CNC lathe turning involves several core processes:

- Facing: Creating a flat surface at the end of the workpiece.

- Turning: Shaping the external diameter by cutting the surface perpendicular or parallel to the axis of rotation.

- Threading: Producing screw threads through cutting or forming.

- Boring: Enlarging internal diameters with precise control.

- Grooving: Cutting narrow channels or grooves into the part surface.

Each machining operation can be programmed with varying parameters such as feed rate, cutting speed, and depth of cut to optimize the tool life and surface finish.

Custom CNC lathe turning offers unparalleled advantages, including:

- Unmatched Precision and Repeatability: Fine control over tool paths allows manufacturers to achieve tight tolerances, often within microns, which is critical for industrial equipment that must withstand rigorous operational stresses.

- Flexibility in Material Use: CNC lathes can work with a broad range of materials, from hard metals like stainless steel and titanium to softer materials such as aluminum, brass, and engineering plastics, all without sacrificing precision.

- Efficient and Automated Production: Automation reduces manual labor and cycle times, enabling high throughput with consistent quality. This makes CNC lathe turning well-suited for both small batch production and large-scale manufacturing.

- Complex Geometries: CNC technology allows for intricate part designs that would be difficult or impossible to achieve with traditional manual machining. This includes tapered surfaces, complex threads, undercuts, and contoured profiles.

- Reduced Waste: The precise control over machining operations minimizes material wastage, lowering overall production costs and making CNC lathe turning economically advantageous.

For manufacturers and brand owners looking for OEM services, custom CNC lathe turning is a game-changer. Factories specializing in rapid prototyping, CNC machining, and mass production can quickly turn customer designs into reality. This process supports everything from prototype developments to high-volume batch productions with consistent quality.

Companies like Shangchen offer specialized services in custom CNC lathe turning, providing fast turnaround times, quality assurance, and scalability to meet diverse client needs. Their expertise includes working closely with clients to optimize part designs for manufacturability and cost-efficiency.

Additional services often integrated with CNC lathe turning include:

- Rapid Prototyping: Quickly creating initial part designs to verify form, fit, and function before full production.

- Precision Batch Production: Delivering consistent quality across large runs with tight tolerances.

- Post-Processing: Including finishing techniques such as polishing, coating, or heat treatment to enhance performance and durability.

- Quality Control: Employing advanced inspection tools like coordinate measuring machines (CMM) to ensure parts meet exact specifications.

CNC lathe turning is vital in producing components for various industrial equipment, including but not limited to:

- Bearings and Bushings: Precision-machined for minimal friction and wear in machinery.

- Shafts and Axles: Essential for transferring power and rotational motion with high strength and accuracy.

- Flanges and Couplings: Facilitate the assembly of complex mechanical systems with secure, standardized connections.

- Threaded Components: Screws, bolts, and fasteners that require precise thread profiles for secure fastening.

- Hydraulic and Pneumatic Parts: Custom valves, pistons, and cylinders that require tight tolerances for fluid control.

These components require precision machining to meet strict operational standards and durability requirements. CNC lathe turning makes it possible to produce parts that meet the high demands of performance, safety, and reliability in sectors like automotive, aerospace, energy, and heavy machinery.

Selection of materials is critical in CNC lathe turning for industrial equipment components. Common materials include:

- Stainless Steel: Known for corrosion resistance and strength, often used in harsh environments.

- Aluminum: Lightweight and corrosion-resistant, ideal for parts requiring reduced weight.

- Brass: Excellent for applications requiring electrical conductivity and corrosion resistance.

- Titanium: High strength-to-weight ratio and corrosion resistance, used in aerospace and medical applications.

- Engineering Plastics: Such as Nylon or Delrin, used for wear parts or electrical insulators.

Each material requires specific machine settings and tooling considerations to optimize the machining process and achieve the desired finish and dimensional accuracy.

Quality control is essential in CNC lathe turning to guarantee that industrial components function reliably. Common practices include:

- Dimensional Inspection: Using tools like micrometers, calipers, and CMMs to verify part dimensions.

- Surface Finish Testing: Evaluating the smoothness and texture to meet operational or aesthetic criteria.

- Material Testing: Confirming the material composition and mechanical properties through hardness testing or spectrometry.

- Process Validation: Ensuring that machining parameters produce consistent results over production runs.

These quality measures help prevent failures in critical equipment and enhance the longevity and performance of the manufactured parts.

Custom CNC lathe turning is indispensable for industrial equipment component manufacturing, offering precision, efficiency, and flexibility. It allows manufacturers to produce complex parts with rigorous standards and supports both rapid prototyping and large-scale production. By integrating CNC lathe turning services, industrial brands and producers can enhance product quality, reduce costs, and accelerate time to market. The technology's ability to handle various materials and intricate geometries ensures it will remain a cornerstone in modern manufacturing.

CNC lathe turning can machine a variety of materials including metals like steel, aluminum, brass, titanium, as well as plastics and composite materials depending on the lathe specifications. The choice depends on the application requirements and machining parameters.

The precision is typically within microns, with tolerances often held to ±0.01 mm or better, depending on the machine, tooling, and process control employed. This makes it suitable for critical industrial components.

Industries such as automotive, aerospace, electronics, medical devices, energy, and heavy machinery heavily rely on CNC lathe turned components due to their reliability and consistency.

Yes, CNC lathe turning is highly versatile and suited for producing both prototypes and high-volume batch production runs, allowing flexibility throughout the product development lifecycle.

CNC turning involves rotating the workpiece against a stationary cutting tool to create cylindrical or symmetrical shapes, while CNC milling uses rotating cutting tools to remove material from a stationary workpiece to create more complex and varied geometries.

[1](https://www.mecanumeric.com/3-4/technologies/lathe/)

[2](https://macfab.ca/capabilities/cnc-turning/)

[3](https://yijinsolution.com/cnc-machining/types/lathe/parts/)

[4](https://www.youtube.com/watch?v=vEr2CJruwEM)

[5](https://www.mnbprecision.com/what-is-cnc-turning/)

[6](https://firstmold.com/cnc-turning-service/)

[7](https://www.ricardo-barbosa.com/cnc-lathe-machine-parts-and-components/)

[8](https://www.shutterstock.com/video/search/cnc-lathe-turning)

[9](https://xometry.pro/en/articles/cnc-turning-overview/)

[10](https://xometry.asia/en/cnc-turning/)

[11](https://proformmfg.com/industrial-machinery-components/)

[12](https://www.gettyimages.com/videos/cnc-turning)

[13](https://en.dmgmori.com/news-and-media/blog-and-stories/blog/blg24-15-cnc-turning)

[14](https://www.protolabs.com/services/cnc-machining/cnc-turning/)

[15](https://automechgroup.com/cnc-machining-lathes-what-it-is-and-how-it-works)

[16](https://www.shutterstock.com/video/clip-3581067493-witness-precision-cnc-lathe-machining-metal-cut)

[17](https://www.youtube.com/watch?v=AwZPyzGEGG4)

[18](https://www.rapiddirect.com/services/cnc-turning/)

[19](https://at-machining.com/cnc-lathe-parts/)

[20](https://www.shutterstock.com/video/search/cnc-lathe-parts)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes