Views: 222 Author: Amanda Publish Time: 2025-08-10 Origin: Site

Content Menu

● Advantages of 5-Axis Machining

>> 1. Enhanced Precision and Accuracy

>> 2. Capability to Machine Complex Shapes and Contours

>> 3. Significant Reduction in Setup Times and Improved Throughput

>> 4. Improved Tool Life and Reduced Tooling Costs

>> 5. Superior Surface Finish Quality

>> 6. Increased Material Removal Rates

>> 7. Enhanced Accessibility of Hard-to-Reach Features

>> 8. Flexibility to Work With Various Materials

>> 9. Facilitation of Advanced Manufacturing Techniques

>> 10. Support for Lean Manufacturing and Cost Savings

● Applications of 5-Axis Machining

● FAQs

>> 1. What types of materials can be machined using 5-axis technology?

>> 2. How does 5-axis machining reduce production time?

>> 3. Is 5-axis machining suitable for small batch or prototype production?

>> 4. What software is required for programming 5-axis machining?

>> 5. How does 5-axis machining improve tool life?

In today's rapidly evolving manufacturing landscape, precision, efficiency, and flexibility have become indispensable. 5-Axis Machining stands as one of the most advanced and versatile manufacturing techniques available, revolutionizing how complex components are designed and produced. For industries such as aerospace, automotive, medical devices, and mold making, this machining process offers substantial benefits that enhance product quality and improve production productivity. This article explores in detail the key advantages of 5-Axis Machining, explaining why it is becoming a preferred choice among OEMs, brand owners, wholesalers, and manufacturers worldwide.

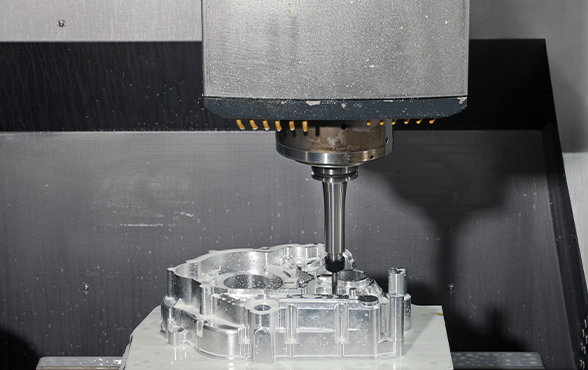

Understanding the advantages begins with knowing what 5-Axis Machining entails. Traditional 3-axis CNC machining involves moving a cutting tool along three linear axes: X, Y, and Z. In contrast, 5-Axis Machining incorporates two additional rotational axes (commonly termed A and B axes), enabling the tool or workpiece to tilt and rotate. This enhanced flexibility allows the cutting tool to approach the workpiece from virtually any direction, offering tremendous freedom to machine intricate and complex parts with superior precision.

The five axes usually operate simultaneously, which means a tool can cut more complex shapes in a single setup than would otherwise require multiple setups on a 3-axis machine. This capability reduces manual repositioning and lowers the risks of inaccuracies due to re-fixturing.

A primary strength of 5-Axis Machining lies in its ability to achieve exceptional precision and accuracy. By tilting and rotating the cutting tool, manufacturers can access complex surfaces in a single, stable setup, limiting the cumulative errors that come from multiple repositionings. This is crucial in sectors like aerospace and medical devices, where even minor deviations can lead to component failures.

The simultaneous multi-axis control ensures tighter tolerances are maintained, which translates into higher part quality and improved performance in their intended applications.

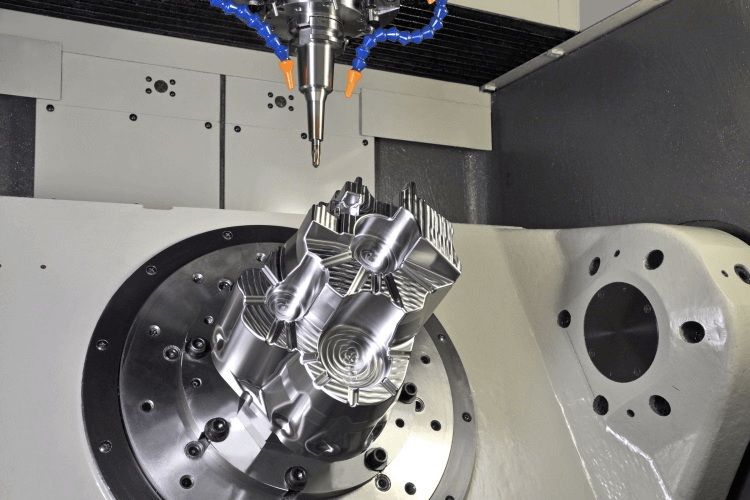

5-Axis Machining opens doors to machining intricate and highly contoured parts that 3-axis machines cannot achieve efficiently or at all. For example, aerodynamic components such as turbine blades, aircraft structural parts, and ergonomic implants often feature complex 3D curves which require multi-axis tool movement.

This freedom enables designers to innovate without being limited by manufacturing constraints, encouraging the creation of lightweight, aerodynamically efficient, and functionally optimized parts.

Traditional machining of complex parts typically demands multiple setups to access all features, each requiring time-consuming realignment and fixturing. With 5-Axis Machining, many intricate features can be cut in a single setup because the tool's multi-directional movement allows continuous access to difficult-to-reach areas.

Reducing the number of setups not only shortens the total manufacturing time but also diminishes labor costs and increases overall productivity. This advantage is particularly beneficial in small batch and prototype manufacturing where time-to-market is critical.

Because 5-Axis machines maintain the optimal cutting angle throughout the machining process, cutting forces are distributed more evenly, minimizing undue stress on the cutting tools. Tools maintain consistent contact with the workpiece, reducing wear and breakage.

This extension of tool life leads to fewer tool changes and tool purchases, directly impacting the cost-effectiveness of production. Additionally, 5-Axis Machining often uses shorter, more rigid tools that naturally last longer and allow for higher spindle speeds and feed rates.

The ability of 5-Axis Machining to maintain optimal tool engagement with the material results in smoother cuts and finer surface finishes than achievable with conventional machining. This reduces or even eliminates the need for secondary finishing operations like polishing or grinding, saving additional time and cost.

Industries with strict surface quality requirements, such as medical device manufacturing or aerospace, find this particularly advantageous in meeting stringent regulatory specifications.

5-Axis Machining can maintain the most effective tool orientation at all times, leading to optimized cutting conditions. This facilitates higher material removal rates without sacrificing part quality.

The ability to machine complex geometries more efficiently shortens production cycles and increases overall manufacturing throughput, providing a competitive advantage in markets demanding fast delivery.

Some parts include intricate internal or external features that are physically difficult to reach with fixed-axis machining. The dynamic rotation and tilting capabilities of 5-Axis Machining ensure that these features can be accessed and machined precisely without complicated tooling or multiple setups.

This turn-key approach simplifies fabrication processes for parts with deep cavities, steep walls, or complex angles, and enables the complete machining of challenging components.

The flexibility of 5-Axis Machining is not limited to geometries but extends to materials as well. It can proficiently handle a wide range of materials including aluminum, titanium, various steels, plastics, composites, and exotic alloys.

This versatility means manufacturers can prototype and produce parts in multiple materials with consistent quality, catering to diverse industries from aerospace to consumer electronics.

5-Axis Machining integrates well with modern manufacturing practices, including:

- Rapid Prototyping: Quickly realizing functional prototypes with accurate and complex geometries.

- Hybrid Manufacturing: Combining additive manufacturing (3D printing) with 5-axis machining for post-processing, resulting in high precision and improved surface finishes of printed parts.

- Multi-Task Machining: Streamlining the production workflow by combining turning, milling, and drilling processes within a single machine setup.

- CAD/CAM Software Integration: Sophisticated programming tools enable efficient generation of complex tool paths that capitalize on 5-axis capability.

This integration empowers manufacturers to optimize production flow, reduce lead times, and improve design-to-part accuracy.

By reducing setups, tool changes, and secondary finishing, 5-Axis Machining supports lean manufacturing philosophies aimed at eliminating waste and increasing efficiency. It lowers inventory overhead by enabling on-demand manufacturing and reduces scrap through higher accuracy.

Long-term, the technology translates into significant cost savings across labor, tooling, time, and materials.

The universal advantages of 5-Axis Machining have made it indispensable across multiple industries:

- Aerospace: Manufacturing aerospace components such as turbine blades, engine housings, airframe structures, and landing gear parts that require complex contours and tight tolerances.

- Medical Devices: Producing custom implants, orthopedic prosthetics, surgical instruments, and dental restorations that fit precise anatomical shapes.

- Automotive: Creating molds, dies, engine parts, and high-performance prototypes with intricate designs and contoured features.

- Electronics: Fabricating small, precise housings, connectors, and sensor components.

- Tool and Die Making: Crafting detailed molds with multi-axis undercuts and sharp geometries critical for injection molding and casting operations.

- Energy and Turbine Industry: Manufacturing complex impellers, nozzles, and blades that demand both aerodynamic efficiency and high performance.

5-Axis Machining represents a major leap forward in manufacturing capability, offering unparalleled precision, flexibility, and efficiency. By enabling the machining of complex geometries in fewer setups with improved accuracy and surface quality, it significantly reduces production times and costs while elevating product quality. Its capacity to handle diverse materials and integrate with modern manufacturing techniques makes it vital across industries such as aerospace, medical, automotive, and electronics.

For OEMs, brand owners, and manufacturers aiming at competitive advantage through superior components, investing in or outsourcing to 5-Axis Machining services is a strategic decision that drives innovation, efficiency, and profitability in today's demanding market environment.

5-Axis Machining is extremely versatile and can machine a broad range of materials including light metals like aluminum, high-strength titanium alloys, stainless steel, plastics, composites, and specialty materials. The precise tool control facilitates machining even tough or delicate materials efficiently.

By enabling complex parts to be fully machined in a single setup without the need for multiple repositionings, 5-Axis Machining cuts down on setup times and manual labor. This results in faster throughput and decreases overall production lead times.

Yes, 5-Axis Machining offers excellent flexibility suited for both rapid prototyping and small batch production. It delivers precise parts quickly, making it ideal for product development cycles as well as limited manufacturing runs.

Specialized CAD/CAM software capable of generating multi-axis tool paths is essential for 5-axis programming. Advanced software packages allow users to create optimized, collision-free tool movements that fully exploit 5-axis machine capabilities.

By maintaining ideal cutting angles and consistent tool engagement with the workpiece, 5-axis machining reduces tool wear and heat buildup. This leads to less frequent tool replacement and lower tooling costs, enhancing manufacturing cost-effectiveness.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product