Views: 222 Author: Amanda Publish Time: 2025-07-12 Origin: Site

Content Menu

● The Importance of Sheet Metal Fabrication in Modern Industry

● Overview of the Sheet Metal Fabrication Process

>> 2. Cutting

>> 5. Assembly

● Key Materials Used in Sheet Metal Fabrication

● Top Sheet Metal Fabrication Manufacturers and Suppliers in Europe

>> Germany

>> Italy

>> France

● Technological Innovations in European Sheet Metal Fabrication

● How to Choose the Right Sheet Metal Fabrication Partner

● FAQ

>> 1. What are the main processes used by sheet metal fabrication manufacturers and suppliers?

>> 2. Which industries benefit most from sheet metal fabrication services in Europe?

>> 3. How do European sheet metal fabrication manufacturers ensure quality?

>> 4. What materials are commonly used by sheet metal fabrication manufacturers and suppliers?

>> 5. How can I choose the best sheet metal fabrication manufacturer or supplier in Europe?

Sheet metal fabrication is the backbone of countless industries, powering everything from automotive and aerospace to electronics, construction, and medical devices. Europe stands as a global leader in this field, boasting a rich ecosystem of sheet metal fabrication manufacturers and suppliers that combine tradition, innovation, and cutting-edge technology. This article provides a comprehensive exploration of the top sheet metal fabrication manufacturers and suppliers in Europe, delving into their capabilities, the fabrication process, material choices, and the latest trends shaping the industry.

Sheet metal fabrication manufacturers and suppliers play a pivotal role in modern manufacturing. Their expertise enables the transformation of raw metal sheets into high-precision components and complex assemblies used in virtually every sector:

- Automotive: Chassis, body panels, exhaust systems

- Aerospace: Fuselage panels, brackets, enclosures

- Electronics: Enclosures, heat sinks, mounting plates

- Medical Devices: Casings, surgical instruments, hospital equipment

- Construction: Ductwork, roofing, structural supports

The versatility, durability, and cost-effectiveness of sheet metal parts make them indispensable in today's fast-paced, quality-driven markets. Moreover, the ability to rapidly prototype and scale production ensures that manufacturers can meet evolving customer demands and regulatory requirements efficiently.

Sheet metal fabrication is a multi-stage process that transforms flat metal sheets into finished products through a series of precise operations. The main stages include:

- CAD models are created to define the part's geometry.

- Designs are “unfolded” to optimize material usage and prepare for cutting.

- Advanced software tools simulate bending and forming to predict potential issues before production starts.

- Methods include laser cutting, waterjet cutting, plasma cutting, and punching.

- High precision ensures minimal waste and tight tolerances.

- Laser cutting is especially favored for its speed and accuracy, capable of producing complex shapes with smooth edges.

- Removal of sharp edges and imperfections for safety and quality.

- This step is critical to prepare parts for subsequent processes like welding or coating.

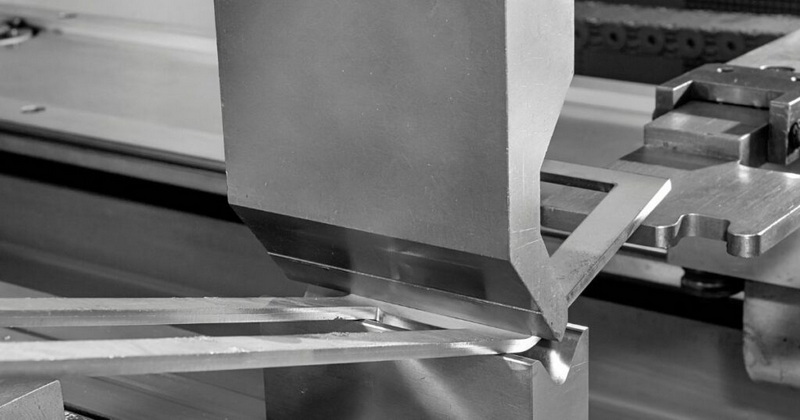

- Press brakes and rolling machines create bends, curves, and complex shapes.

- CNC-controlled machines allow for repeatable precision, essential for batch production.

- Components are joined using welding, riveting, or fasteners.

- Some manufacturers offer turnkey assembly services, integrating multiple fabrication processes into a single workflow.

- Processes such as powder coating, anodizing, and plating enhance durability and appearance.

- Surface treatments also protect against corrosion, wear, and environmental factors.

- Dimensional and visual inspections ensure compliance with specifications.

- Many suppliers use coordinate measuring machines (CMM) and laser scanners for high-accuracy quality control.

Sheet metal fabrication manufacturers and suppliers in Europe work with a broad range of materials, each selected for its unique properties:

| Material | Key Properties | Common Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, strength | Food, medical, marine |

| Aluminum | Lightweight, conductive | Aerospace, electronics |

| Carbon Steel | Cost-effective, strong | Automotive, construction |

| Copper | Conductivity, malleability | Electrical, HVAC |

| Brass | Decorative, corrosion resistant | Plumbing, musical instruments |

In addition to these traditional metals, some manufacturers are exploring advanced alloys and composite materials to meet specific industry needs, such as enhanced strength-to-weight ratios or improved thermal properties. This material diversity allows sheet metal fabrication manufacturers and suppliers to tailor solutions precisely to client requirements.

Germany is renowned for its engineering prowess and precision manufacturing. Leading sheet metal fabrication manufacturers and suppliers include:

- De Crignis GmbH: Founded in 1867, this Augsburg-based company is a pioneer in precision sheet metal fabrication, serving industries ranging from automotive to industrial machinery. Their expertise in complex laser cutting and automated bending systems ensures high-quality, repeatable results.

- LECHNER Maschinenbau: Specializes in machines for sheet metal working, including round bending and welding systems. Their equipment is widely used by manufacturers seeking to produce curved and tubular components with exacting tolerances.

- Hezinger Maschinen GmbH: Known for advanced folding machines and cutting systems, Hezinger supports both small batch and mass production with flexible machinery.

- Boschert GmbH und Co.KG: Offers a wide range of sheet metal work machines and processing centers, with a focus on integrating automation and digital control to optimize workflow efficiency.

Germany's sheet metal fabrication sector benefits from a strong emphasis on research and development, often collaborating with universities and technology institutes to push the boundaries of manufacturing capabilities.

The UK boasts some of Europe's largest and most advanced sheet metal fabrication manufacturers and suppliers:

- Hydram Engineering Ltd: One of the largest in the UK, Hydram offers comprehensive services from design to delivery, with a focus on precision and quality. Their capabilities include laser cutting, CNC punching, and robotic welding, serving sectors such as aerospace, defense, and energy.

- KMF Group: With multiple sites across the UK and Europe, KMF delivers metal fabrication, CNC machining, and precision engineering for sectors like aerospace, telecommunications, and automotive. Their integrated approach allows for complex assemblies and rapid prototyping.

- Universal Fabrications: Specializes in precision machining and project management, providing tailored solutions for high-technology industries.

The UK's manufacturing landscape is supported by government initiatives promoting innovation and skills development, ensuring that sheet metal fabrication manufacturers and suppliers remain competitive on a global scale.

Italy's sheet metal fabrication sector is known for its blend of craftsmanship and technology:

- DAVI - Promau Group: A leader in sheet metal working and processing centers, particularly for large-scale bending and forming. Their machines are used worldwide for producing pipes, beams, and structural components.

- OMCCA: Renowned for round machine manufacturing and profile bending machines, OMCCA serves industries requiring precision tubular components.

- COMAC: Specializes in profile bending machines for a variety of applications, combining Italian design aesthetics with robust engineering.

Italian manufacturers often emphasize customization and flexibility, catering to industries such as luxury automotive, furniture, and industrial design.

France's sheet metal fabrication industry is characterized by innovation and a strong focus on high-tech applications:

- TRUMPF GmbH + Co. KG: Known for advanced laser technologies and automation solutions, TRUMPF is a global leader in sheet metal processing equipment. Their machines enable manufacturers to achieve high throughput with minimal downtime.

- Amada Europe: Offers a comprehensive range of sheet metal fabrication technologies and custom manufacturing solutions. Amada's expertise spans laser cutting, press braking, and punching, with a strong commitment to sustainability.

French suppliers often integrate digital manufacturing platforms, enabling clients to track production in real time and optimize supply chains.

Eastern Europe is emerging as a hub for cost-effective, high-quality sheet metal fabrication:

- UAB SRS Servisas (Lithuania): Offers fine sheet metal work, cutting, welding, and powder coating for industries such as automotive, construction, and medical. They combine competitive pricing with European quality standards.

- Industrum Group (Hungary): Provides industrial equipment and accessories, with expertise in laser cutting and welding. Their strategic location allows easy access to both Western and Eastern European markets.

The region's growing infrastructure and skilled workforce make it an attractive destination for outsourcing sheet metal fabrication services without compromising quality.

Sheet metal fabrication manufacturers and suppliers in Europe are at the forefront of technological advancement, leveraging:

- Automation and Robotics: Automated bending, welding, and assembly lines increase efficiency and consistency while reducing human error. Collaborative robots (cobots) are increasingly used to assist human operators in complex tasks.

- CNC Machining: Computer-controlled cutting and forming ensure high precision and repeatability. CNC technology also supports flexible manufacturing, allowing quick changeovers between product variants.

- Laser and Waterjet Cutting: Enable intricate designs and reduce material waste. Laser cutting, in particular, allows for high-speed processing of thin and thick sheets alike.

- Industry 4.0 Integration: Real-time monitoring, predictive maintenance, and smart manufacturing enhance productivity. Data analytics and IoT connectivity enable manufacturers to optimize machine usage and reduce downtime.

- Sustainable Manufacturing: European manufacturers are adopting eco-friendly processes, such as energy-efficient machinery, recycling scrap metal, and using non-toxic surface treatments to reduce environmental impact.

These innovations not only improve product quality and lead times but also help manufacturers meet increasingly stringent regulatory and customer demands.

Selecting the ideal sheet metal fabrication manufacturer or supplier is crucial for project success. Consider the following factors:

- Technical Capabilities: Ensure the supplier can handle the required materials, tolerances, and volumes. Verify their experience with similar products or industries.

- Certifications: Look for ISO, CE, or industry-specific certifications, which demonstrate compliance with quality and safety standards.

- Quality Assurance: Robust inspection and testing protocols are essential. Ask about their quality control processes and equipment.

- Lead Times: Evaluate the supplier's ability to meet your deadlines, especially for urgent or large-scale projects.

- Customer Service: Responsive communication and technical support foster smooth collaboration. A partner who understands your needs can provide valuable design and process advice.

- Pricing: Balance cost with quality and reliability. Beware of suppliers offering prices that seem too low, as this may indicate compromised standards.

- Prototyping and Flexibility: A good partner should support rapid prototyping and be flexible enough to accommodate design changes or custom requirements.

Visiting the facility or requesting sample parts can also help assess a supplier's suitability and build trust.

Europe's sheet metal fabrication manufacturers and suppliers set the benchmark for quality, innovation, and reliability. Their ability to deliver custom solutions across diverse industries has cemented their reputation on the global stage. As automation, digitalization, and advanced materials continue to evolve, European sheet metal fabrication will remain at the cutting edge, driving progress in manufacturing worldwide. For companies seeking OEM services, partnering with a European sheet metal fabrication expert ensures access to precision engineering, high-quality production, and a commitment to sustainability and continuous improvement.

Sheet metal fabrication manufacturers and suppliers typically use processes such as laser cutting, waterjet cutting, punching, bending, welding, and surface treatment. These methods allow for the creation of complex shapes and assemblies with high precision.

Key industries include automotive, aerospace, electronics, medical devices, construction, and energy. Sheet metal fabrication manufacturers and suppliers provide components that are essential for these sectors' products and infrastructure.

Quality is maintained through the use of advanced CNC machinery, rigorous inspection protocols, adherence to international standards (such as ISO), and continuous staff training. Many suppliers also invest in automation and real-time monitoring systems.

Common materials include stainless steel, aluminum, carbon steel, copper, and brass. The choice depends on the application's requirements for strength, weight, corrosion resistance, and conductivity.

Consider factors such as technical capabilities, certifications, quality assurance processes, lead times, customer service, and pricing. Visiting the facility or requesting sample parts can also help assess a supplier's suitability.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal