Views: 222 Author: Amanda Publish Time: 2025-10-06 Origin: Site

Content Menu

● Tooling and Cost Considerations

● Design Flexibility and Complexity

● Advantages and Disadvantages

>> Advantages of Injection Molding

>> Disadvantages of Injection Molding

● Selecting Between Injection Molding and Casting

● FAQ

>> 1. What materials can injection molding process?

>> 2. How much do injection molding molds cost compared to casting molds?

>> 3. Which method is faster for mass production?

>> 4. Can injection molding be used with metals?

>> 5. Do parts require post-processing in these processes?

In the competitive world of manufacturing, selecting the right production process can be the difference between profitability and inefficiency. Injection molding and casting are two widely utilized techniques, each offering unique benefits tailored to specific applications, materials, and production scales. This article delves deeply into the distinctions between injection molding and casting, providing insights valuable for manufacturers like Shangchen who offer fast prototyping, precision CNC machining, batch production, and OEM services to global brands, wholesalers, and producers. Emphasizing the advantages of injection molding, the article maintains fluidity and includes relevant details to support decision-making.

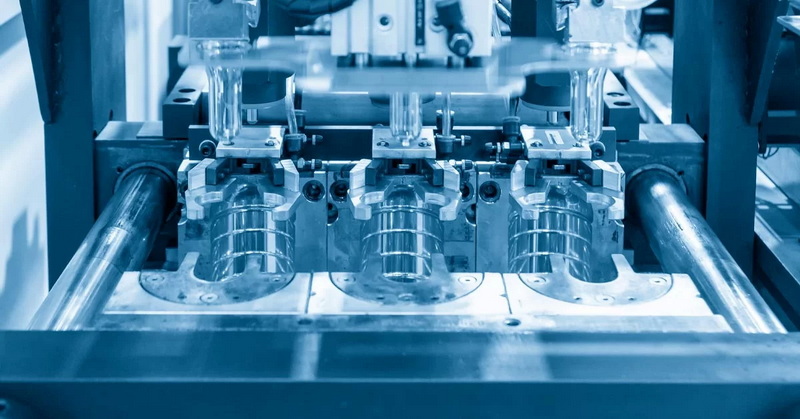

Injection molding is a precision manufacturing technique where molten plastic or polymer is injected into a finely machined metal mold under high pressure. The material cools, solidifies, and the mold opens to eject a finished part. This automated process is ideal for producing large volumes of complex plastic parts with excellent repeatability, tight tolerances, and smooth finishes.

Key features of injection molding include:

- Use of thermoplastics, thermosets, and polymer blends.

- Suitable for medium to very high production volumes (thousands to millions of parts).

- Complex steel or aluminum molds requiring detailed CNC machining and temperature control.

- Common applications: automotive components, consumer electronics housings, medical devices, household items, and more.

Casting is a more traditional manufacturing method where liquid material—metal, plastic, or other substance—is poured or injected into a mold to solidify. As an ancient technique, casting covers multiple methods, including metal die casting and urethane casting for plastics.

Key aspects of casting:

- Utilizes metals like aluminum, zinc, copper, as well as thermoset plastics.

- Best suited for lower volume production, from prototypes to small batches.

- Molds vary from simple silicone or sand molds to more sophisticated metal dies.

- Common in metal parts production (automotive hardware, architectural elements) and limited plastic runs.

A major factor influencing the decision between these processes is tooling complexity and expense. Injection molding molds are constructed from hardened steel or aluminum, designed to withstand high pressure and temperature. Tooling demands exact machining and polishing, resulting in significant upfront investment. This cost becomes economically viable with large production volumes as mold cost is amortized.

Conversely, casting molds—especially for urethane or silicone casting—often have simpler designs and lower upfront costs. Metal casting dies require investment but are generally less complex than injection molds. This makes casting advantageous for rapid prototyping or limited production where high tooling cost is prohibitive.

Injection molding boasts fast cycle times of seconds to a minute per part, supported by automation enabling thousands of units daily. This makes it highly effective for large-scale manufacturing.

Casting processes typically take longer per cycle due to pouring, curing or solidification, and any necessary post-processing. Production volumes are lower, aligning casting more with prototyping or specialty components than mass production.

Injection molding primarily accommodates thermoplastics and thermosets of relatively low viscosity for smooth injection and rapid cooling. It supports a wide range of plastics with customizable fillers for reinforced strength or enhanced properties.

Casting caters to a wider slate of materials, including metals, thermoset plastics, ceramics, and glass. Die casting is metal-specific, while urethane casting specializes in complex polymer prototypes, offering flexibility when plastics compatible with injection molding are not suitable.

Injection molded parts feature tight tolerances, exacting dimensional accuracy, and smooth finishes owing to precision molds. Complex details and texturing can be integrated directly into molds, requiring minimal finishing post-ejection.

Casting quality depends on the process and mold type. Metal cast parts usually need secondary grinding or polishing for aesthetic refinement, though some achieve near-net shape. Urethane cast plastics may require trimming for visible mold seams and finishing.

Injection molding offers exceptional design versatility capable of creating intricate geometries including internal cavities, undercuts, living hinges, threads, and surface textures. The process can consolidate multiple assembled components into one molded part.

Casting methods also permit complex designs but may face shape limitations in metal casting due to material flow and solidification constraints. Post-casting machining can overcome some complexity barriers but adds cost and time.

- Cost-effective for high volume production with low per-unit costs.

- High dimensional accuracy and repeatability.

- Broad plastic material compatibility.

- Efficient automation reduces labor expenses.

- Excellent surface finish and functional part properties.

- High initial tooling and mold fabrication cost.

- Longer lead time to produce molds (weeks to months).

- Less economical for low volume or prototype-only production.

- Lower tooling expenses and faster mold turnaround.

- Wide material range including metals and thermosets.

- Better suited for low volume and prototype parts.

- Enables production of large and complex-shaped parts difficult for injection molding.

- Slower production and limited output rates.

- Typically lower surface finish and accuracy.

- Additional post-processing usually required.

Injection molding dominates in the production of plastic products requiring complex shapes and high volumes — such as automotive dashboards, medical syringes, consumer electronics casings, toys, and household goods.

Casting is prominent in metal-intensive applications such as engine blocks, plumbing fixtures, jewelry, and metal hardware, as well as urethane plastic prototypes and small batch molded parts requiring thermal or mechanical properties not achievable via injection molding.

When deciding between injection molding and casting, manufacturers and product developers should consider:

- Production volume: Injection molding excels above 10,000 units; casting benefits lower volumes.

- Material needs: Use injection molding for thermoplastics; casting for metal parts or specialized plastics.

- Complexity: Injection molding offers finer detail for plastic parts; casting allows for larger or heavier parts.

- Cost & lead time: Casting offers faster prototyping and lower upfront expense; injection molding requires greater initial investment.

- End-use requirements: Consider mechanical strength, thermal properties, surface finish, and part tolerances.

Injection molding and casting remain foundational manufacturing processes, each optimized for specific materials, volumes, and product requirements. Injection molding stands out as the premier choice for producing high-quality plastic components at scale rapidly and cost-effectively, boasting superior accuracy and finish. Casting, with its versatility and lower startup investment, excels in prototyping, metal part fabrication, and small batch production.

Manufacturers like Shangchen maximize competitive advantage by understanding these differences and aligning their OEM service offerings to client needs—ensuring efficient, high-precision production tailored to diverse international markets.

Injection molding primarily processes thermoplastics (ABS, polycarbonate, nylon, polypropylene) and some thermosets, often enhanced with fillers for mechanical or electrical properties.[2][5]

Injection molding molds require hardened steel or aluminum with precise machining, leading to higher upfront costs than casting molds, which can be simpler, cheaper silicone or metal dies.[1][7]

Injection molding cycles can produce hundreds to thousands of parts daily due to automation, whereas casting generally has slower cycle times and lower output, ideal for prototypes or small runs.[6][1]

No, injection molding is suitable for plastics. Metal parts require casting methods such as die casting or investment casting using molten metal.[5][2]

Injection molded parts often need minor finishing like deflashing. Cast parts, especially metals, frequently require grinding, polishing, or machining to meet surface quality standards.[2][5]

[1](https://xometry.pro/en/articles/vacuum-casting-vs-injection-molding/)

[2](https://www.zetwerk.com/resources/knowledge-base/die-casting/difference-between-die-casting-injection-molding/)

[3](https://www.gallagherseals.com/blog/the-difference-between-injection-molding-and-cast-molding)

[4](https://www.boyiprototyping.com/injection-molding-guide/die-casting-vs-injection-molding/)

[5](https://www.xometry.com/resources/injection-molding/injection-molding-vs-casting/)

[6](https://www.rapiddirect.com/blog/die-casting-vs-injection-molding/)

[7](https://knowledgecenter.mearthane.com/injection-molding-vs.-cast-molding)

[8](https://prototool.com/die-casting-vs-injection-molding/)

[9](https://www.3erp.com/blog/injection-molding-vs-urethane-casting-differences-and-comparison/)

[10](https://www.immould.com/injection-molding-vs-casting/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product