Views: 222 Author: Amanda Publish Time: 2025-10-08 Origin: Site

Content Menu

● Introduction to Injection Molding Tooling Costs

● Material Selection Impact on Tooling Costs

>> Mold Materials: Aluminum vs. Steel

● Production Volume Considerations

● Tooling Manufacturing Methods

● Cooling System Design and Cycle Time

● Secondary Operations and Surface Finishing

● Labor and Geographic Factors

● Strategies to Optimize Injection Molding Tooling Costs

>> 1. What materials are commonly used for injection molds, and how do they affect cost?

>> 2. How does part design complexity impact tooling costs?

>> 3. What role does production volume play in selecting mold types?

>> 4. Can 3D printed molds be used for production runs?

>> 5. How does the cooling system affect cycle time and tooling cost?

Injection molding is one of the most widely used manufacturing processes for producing plastic parts with high precision and repeatability. Central to this process is the creation of injection molds or tooling, which are custom-made devices designed to inject molten plastic into specific shapes. For OEM service providers like Shangchen, understanding the factors influencing injection molding tooling costs is essential to optimize production budgets while ensuring product quality. This article offers a comprehensive examination of the top factors that affect tooling costs in injection molding, elaborating on how choices made during design, material selection, and production planning impact overall expenses.

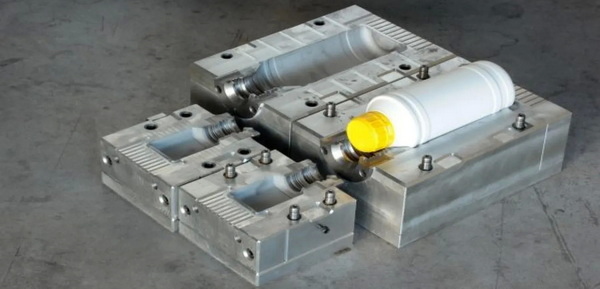

Injection molding molds serve as the blueprint for shaping plastic components. These molds typically consist of two halves forming a cavity that mirrors the final product. Tooling is a significant upfront investment that can range from a few hundred dollars for simple prototype molds to over $100,000 for complex, multi-cavity steel molds designed for high-volume manufacturing runs.

The substantial fixed cost of tooling is amortized over the number of parts produced, making injection molding highly cost-effective for large production volumes. At the same time, tooling quality and complexity have a direct effect on the part's quality, manufacturing efficiency, and long-term durability.

The selection of mold and resin materials strongly determines tooling costs.

- Aluminum molds are less expensive and quicker to machine, making them ideal for prototyping and low to medium volume production (typically 1,000 to 10,000 parts). However, aluminum molds have a shorter lifespan due to lower hardness and wear resistance.

- Steel molds, especially hardened steel, offer durability and are preferred for high-volume production (tens to hundreds of thousands of parts). They are more costly and time-consuming to manufacture but provide superior longevity.

The type of plastic resin used also influences tooling cost since certain materials require molds that withstand higher pressures and temperatures.

- Commodity plastics like polyethylene (PE) and polypropylene (PP) are commonly used and cheaper to mold.

- Engineering plastics such as polycarbonate (PC), nylon, or PEEK demand molds with enhanced wear resistance and might need special coatings or surface treatments, increasing mold complexity and cost.

The intricacy of the part design is a major factor affecting mold cost. Complex designs require advanced mold features and precise machining, which increase tooling expenses.

Key design features impacting cost include:

- Undercuts require side-actions or slides in the mold, adding mechanical complexity.

- Thin walls and deep ribs necessitate exacting mold tolerances and contribute to higher mold wear.

- Tight dimensional tolerances increase finishing and quality-control efforts.

- Surface finishes such as mirror polishing or texturing add labor and time during mold fabrication.

Simplifying part design can reduce mold complexity and costs without compromising functionality. Following Design for Manufacturing (DFM) guidelines — like including draft angles and avoiding complex undercuts — helps optimize tooling expenses.

Mold dimensional size affects tooling costs directly:

- Larger parts require bigger molds, which increases raw material consumption and machining time.

- Multi-cavity molds produce several parts per injection cycle, increasing upfront tooling costs but lowering the cost per part by boosting production output.

Balancing mold size and cavity count against production needs is important. Smaller molds with fewer cavities suit prototyping or low-volume runs, while large, multi-cavity steel molds are suitable for mass production.

The production quantity significantly influences tooling decisions and costs.

- For low-volume production (under 1,000 parts), rapid tooling such as 3D printed molds or soft aluminum molds are cost-effective but less durable.

- Mid-volume runs (thousands of parts) often use aluminum molds with moderate durability.

- High-volume manufacturing (100,000+ parts) justifies investment in hardened steel molds that last longer and produce consistent quality parts.

As production volume increases, tooling cost per part decreases dramatically since initial fixed tooling expenses spread across greater output.

Different manufacturing methods for molds affect tooling cost and lead time.

- CNC machining is standard for steel and aluminum molds, offering precision but higher labor and machine costs due to setup and operation complexity.

- Electrical Discharge Machining (EDM) is used for intricate mold details and hard-to-machine areas, adding cost but enabling complex designs.

- 3D printing and rapid tooling enable quick production and lower cost for prototypes or low-volume molds, but these molds degrade rapidly and are unsuitable for long production runs.

Efficient mold cooling is essential for reducing cycle times during injection molding. Cooling channels integrated into molds enable faster solidification of plastics, enhancing throughput.

While elaborate cooling systems increase the initial mold cost, they result in lower per-part costs by shortening production cycle times and reducing machine operating expenses.

Shorter project timelines often come with premium costs. Rush orders require expedited mold machining, overtime labor, and prioritized scheduling, all of which increase tooling costs. Planning ahead and flexible lead times can reduce manufacturing expenses significantly.

Additional mold features and post-processing steps impact cost:

- Coatings like nitriding or chrome plating improve mold wear resistance but increase tooling price.

- Mold polishing or texturing for aesthetic surface finishes adds time and labor.

- Secondary operations such as machining critical areas or implementing prototype modifications contribute to cost.

Labor intensity for mold design, machining, inspection, and maintenance factors into tooling costs. Moreover, geographic location affects costs due to variations in labor rates, overhead, and logistics.

OEM providers often balance local high-quality tooling with cost-competitive offshore or nearshore suppliers to optimize expenses.

- A small, single-cavity aluminum mold for low-volume runs might cost between $1,500 and $5,000.

- Larger steel molds with multiple cavities designed for high-volume manufacturing can range from $25,000 to over $100,000.

- Part cost per unit decreases from around $4-$5 in low volume to under $2 in high-volume production due to tooling amortization.

- Engage tooling experts early in the design stage to apply DFM principles.

- Choose mold material suitable to production volume and part requirements.

- Use rapid tooling or 3D printing for prototypes and low-volume orders.

- Design efficient cooling channels to minimize cycle time.

- Avoid rush orders by planning production schedules in advance.

- Consider refurbishing existing molds or using multi-cavity molds to reduce costs.

Injection molding tooling costs are influenced by various interconnected factors, including material selection, part complexity, mold size, production volume, manufacturing processes, and secondary operations. While the initial tooling investment can be considerable, careful planning and strategic choices enable manufacturers to optimize costs and produce high-quality parts efficiently. Understanding these cost drivers helps OEM service providers like Shangchen deliver competitive, customized injection molding solutions that align with client production goals and budgets.

Molds are usually made from aluminum for low to mid-volume production due to lower cost and easier machining. Steel molds, especially hardened steel, are used for high-volume runs because of their durability but come at a higher price point. The choice depends on required mold life and production quantity.

Complex features such as undercuts, thin walls, and tight tolerances require additional mold components like slides and side-actions, increasing machining complexity and tooling costs. Simplifying part geometry reduces these expenses.

Higher production volumes justify more expensive, durable steel molds with multiple cavities, reducing cost per part through scale. Low-volume projects favor cheaper, less durable molds such as aluminum or 3D printed options.

3D printed molds offer a cost-effective and quick solution for prototypes and low-volume runs but lack durability and precision for long-term, high-volume manufacturing.

An optimized cooling system reduces cycle time, improving productivity and lowering per-part costs, though it may increase initial mold manufacturing complexity and cost.

[1](https://www.jaycon.com/injection-moulding-price-a-2025-guide-for-engineers-procurement/)

[2](https://formlabs.com/blog/injection-molding-cost/)

[3](https://www.rpproto.com/blog/injection-molding-cost)

[4](https://moldie.net/injection-mold-costs/)

[5](https://advancedplastiform.com/a-guide-to-injection-molding-tooling/)

[6](https://jiga.io/injection-molding/injection-mold-tooling-comprehensive-guide/)

[7](https://www.bh-med.com/application/injection-mold-tooling-cost)

[8](https://www.ace-mold.com/plastic-injection-mold-cost/)

[9](https://www.protolabs.com/resources/design-tips/11-tips-to-reduce-injection-molding-costs/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product