Views: 222 Author: Amanda Publish Time: 2025-10-08 Origin: Site

Content Menu

● Understanding Injection Molding: The Basics

● AI Integration in Injection Molding

>> Machine Learning and Data Analytics

● AI Applications in Injection Molding

>> Process Parameter Optimization

>> Defect Detection and Quality Control

>> Energy Efficiency Management

>> Advanced Mold and Part Design

● Benefits of AI in Injection Molding

● Frequently Asked Questions (FAQ)

>> 1. How does AI improve quality control in injection molding?

>> 2. Can AI predict maintenance needs for injection molding machines?

>> 3. What is the role of machine learning in injection molding process optimization?

>> 4. How does AI contribute to energy savings in injection molding?

>> 5. Are AI-generated designs reliable for injection molding production?

Injection molding stands as one of the most essential manufacturing processes for producing high-precision plastic parts at scale. As manufacturing demands grow for faster production, tighter tolerances, and cost-efficiency, artificial intelligence (AI) is playing an increasingly pivotal role in revolutionizing this process. By integrating AI technologies, injection molding has evolved beyond traditional methods to become smarter, more efficient, and more precise—bringing substantial improvements in quality, throughput, and sustainability. This article delves deeply into how AI is transforming injection molding, exploring the technology behind it, practical applications, and the wide-ranging benefits it offers.

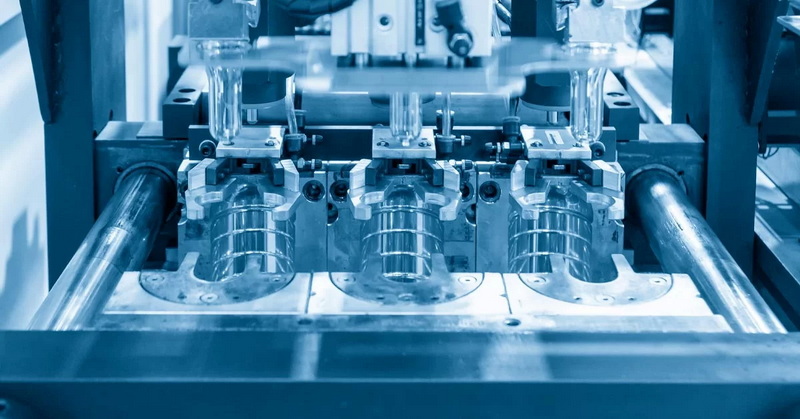

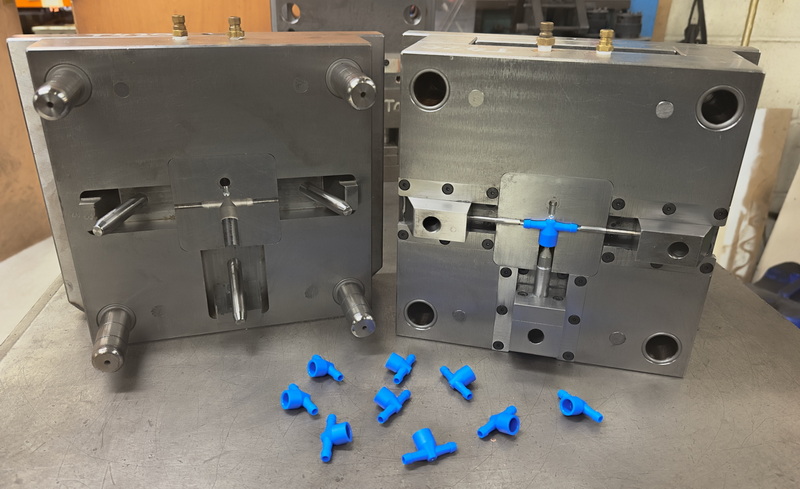

Injection molding is a manufacturing method for shaping plastics by injecting molten material into a mold cavity. The raw plastic material, usually in pellet form, is fed into a heated barrel, where it melts into a liquid state. This molten plastic is then injected at high pressure into a mold, which shapes the material into the final product. Once cooled and solidified, the mold opens, and the finished part is ejected.

The standard injection molding cycle involves several key stages:

- Mold Clamping: The two halves of the mold close securely, held by strong clamping force to prevent any gaps.

- Injection: Molten plastic is injected at high pressure into the mold cavity, filling every detail of the mold.

- Dwelling and Packing: Pressure is maintained to pack the material and compensate for shrinkage during cooling.

- Cooling: The plastic cools and solidifies, a phase that can be time-consuming due to plastic's insulating properties.

- Mold Opening and Ejection: The mold opens, and ejector pins push the finished part out.

- Post-Ejection: Excess material such as runners or gates are removed for finishing.

Each stage requires precise control over temperature, pressure, timing, and machine settings to produce high-quality parts consistently. Minor variations can lead to defects such as warping, bubbles, or incomplete filling, impacting product quality and increasing waste. This is where AI begins to make a transformative impact.

The integration of AI technologies in injection molding maximizes efficiency and precision by enabling real-time monitoring, control, and predictive capabilities. The core technology includes machine learning algorithms, smart automation, and sensor data analytics that help optimize the entire injection molding process.

Machine learning algorithms analyze vast amounts of data from sensors monitoring temperature, pressure, cycle times, and material flow patterns. These algorithms identify hidden correlations and patterns that humans might miss, allowing continuous improvement and adaptation to differing production conditions such as material batch changes or ambient temperature fluctuations. This results in:

- More stable process parameters

- Reduced cycle times

- Lower defect rates

- Consistent product quality across production runs

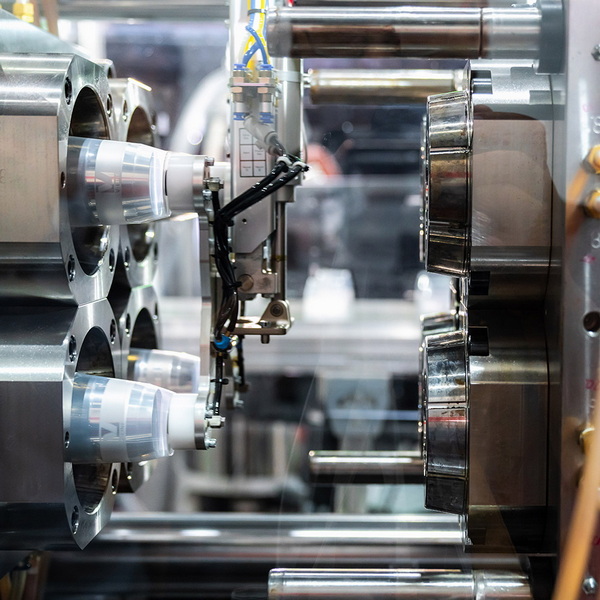

AI-driven injection molding systems are increasingly integrated with IoT devices and robotics, creating smart factories. Sensors embedded in molding machines and molds relay real-time data to centralized AI systems. These systems monitor equipment status, detect anomalies early, and enable automatic adjustments without human intervention. Communication between machines helps coordinate workflows and improve overall equipment effectiveness (OEE).

Injection molding AI functions as a crucial element in Industry 4.0 manufacturing environments. With connected devices, cloud computing, and big data analytics, manufacturers gain full visibility into their production lines, enabling predictive maintenance, supply chain optimization, and energy management. AI leverages this connected ecosystem to ensure that injection molding operations run smoothly, maintain quality assurance, minimize downtime, and reduce costs.

AI continuously adjusts key parameters like injection speed, holding pressure, and cooling time based on real-time data feedback. This dynamic tuning minimizes cycle time without sacrificing quality and reduces material usage and waste. Optimized parameters improve part consistency—vital for high-precision applications like medical devices.

Traditional quality inspection methods rely on manual visual checks or offline measurements prone to errors and delays. AI-powered machine vision systems analyze molded parts as they exit molds, inspecting every component for defects such as warping, short shots, or burrs with unmatched accuracy. Defective parts are identified early, enabling quick corrective actions and reducing scrap rates.

Unexpected equipment failures cause costly downtime and missed deliveries. AI systems analyze sensor data to predict when components like screws, barrels, or ejector pins will wear out or malfunction. Scheduled maintenance during planned downtime reduces the risk of sudden breakdowns, extends machine life, and lowers maintenance costs.

Heating barrels, cooling systems, and motors consume substantial energy during injection molding. AI models forecast production demands and adjust energy usage precisely by varying heating cycles and cooling flows. This reduces energy waste and operational costs while maintaining high productivity levels.

AI-assisted design tools help engineers develop molds and parts optimized for injection molding. These tools simulate flow patterns, cooling rates, and potential defects early in the design phase, enabling innovations such as multi-material molding or complex geometries that were previously difficult to produce.

| Benefit | Description |

| Enhanced Precision and Consistency | Tight control of process parameters delivers parts with tight tolerances and uniform qualities. |

| Increased Production Efficiency | AI shortens cycle times and runtime interruptions, boosting throughput and lowering costs. |

| Reduced Scrap and Waste | Early defect detection and optimized processing minimize material scrap and rework. |

| Lower Energy Consumption | Optimized equipment operation cuts energy usage and reduces environmental footprint. |

| Predictive Maintenance | Avoids unexpected breakdowns and maximizes machine availability |

| Innovative Product Design | AI-enabled simulation and optimization allow for more creative and functional part designs. |

The adoption of AI is fundamentally reshaping injection molding, making it smarter, faster, and more sustainable. By combining machine learning, smart automation, and Industry 4.0 principles, AI helps manufacturers achieve better precision, shorter cycle times, and lower operational costs. The continuous feedback and adaptive controls make injection molding not only more efficient but also reliable and predictable—key criteria in today's competitive manufacturing landscape. As more companies embrace AI technologies, injection molding will continue to drive innovation and quality improvements in producing plastic parts for diverse industries globally.

AI uses advanced machine vision and real-time data analytics to detect defects such as warping and short shots during production. This rapid, automated inspection reduces errors and ensures consistent product quality.

Yes, AI monitors machine sensor data to identify signs of wear or potential failure, enabling planned maintenance that minimizes downtime and prolongs machine lifespan.

Machine learning analyzes historical and live production data to continuously refine process parameters, reducing cycle times and improving part consistency.

AI optimizes the operation of heating and cooling systems and motor drives based on production requirements, minimizing unnecessary energy consumption.

AI-assisted designs enable innovative and complex part geometries but still require human review to ensure manufacturability and material compatibility.

[1](https://www.specialchem.com/plastics/guide/injection-molding)

[2](https://sybridge.com/injection-molding-guide/)

[3](https://www.essentracomponents.com/en-us/news/manufacturing/injection-molding/what-is-plastic-injection-molding-and-how-does-it-work)

[4](https://en.wikipedia.org/wiki/Injection_moulding)

[5](https://adrecoplastics.co.uk/injection-moulding-process/)

[6](https://boyanmfg.com/injection-molding-process-steps/)

[7](https://www.youtube.com/watch?v=sBEzE4PCmqM)

[8](https://www.protolabs.com/resources/guides-and-trend-reports/designing-for-moldability-fundamental-elements/)

[9](https://www.xometry.com/resources/injection-molding/basics-of-plastic-injection-molding/)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes