Views: 222 Author: Amanda Publish Time: 2025-08-22 Origin: Site

Content Menu

● Increased Automation and Robotics in CNC Machining

● Artificial Intelligence and Machine Learning Integration

>> Key AI-Driven Enhancements:

● Multi-Axis Machining for Complex Geometries

>> Benefits of Multi-Axis CNC Machining:

● Hybrid Manufacturing and Additive Integration

● High-Speed Machining: Precision at Speed

● Real-Time Monitoring and IoT Connectivity

>> Advantages:

● Software Innovations and Simulation Tools

● Sustainability and Energy Efficiency

● On-Demand Manufacturing and AI-Powered Quoting

● Enhanced Materials and Tooling Technologies

● Collaborative CNC Workflows and Digital Integration

>> 1. What is the role of AI in CNC machining?

>> 2. How does multi-axis CNC machining improve manufacturing?

>> 3. What benefits does hybrid manufacturing offer?

>> 4. How does IoT connectivity impact CNC machining operations?

>> 5. What sustainability practices are emerging in CNC machining?

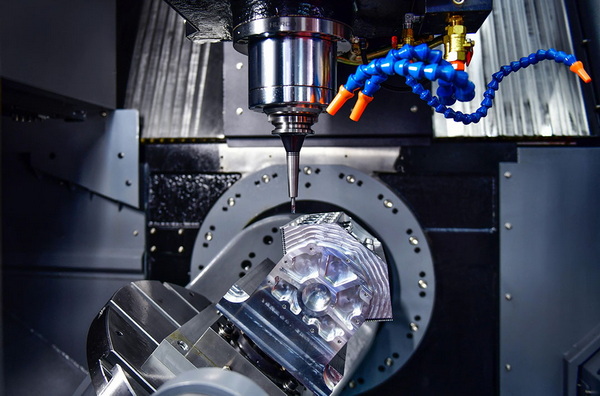

CNC machining has long been a cornerstone of precision manufacturing, enabling the creation of highly detailed and complex components with remarkable accuracy. As technology advances, the CNC machining industry is undergoing a rapid transformation that promises to reshape the way manufacturers operate and compete globally. This article explores the emerging trends in CNC machining that are driving innovation, improving productivity, and enhancing precision in manufacturing.

CNC (Computer Numerical Control) machining involves the automated control of machine tools via computers executing pre-programmed sequences. It is essential in producing precision parts for diverse industries such as aerospace, automotive, medical, and electronics. Today's CNC machining is not just about mechanical cutting but is increasingly integrated with intelligent systems, automation, and software enhancements. These developments create new opportunities for manufacturers to meet stringent tolerances, reduce waste, and accelerate production.

As the industrial landscape evolves, so do customer expectations for quicker turnaround times, higher quality, and more customization. Meeting these demands requires manufacturers to adopt the latest CNC machining innovations that blend mechanical precision with digital intelligence.

One of the most significant trends in CNC machining is the expanded use of automation and robotics. Automated robotic systems are increasingly employed for repetitive tasks such as loading and unloading materials, tool changes, and part inspection. This allows CNC machines to operate continuously with minimal human intervention, reducing labor costs and errors.

- Robotic arms integrated with CNC systems enable 24/7 production, boosting throughput capacity.

- Automation helps optimize resource allocation, allowing skilled personnel to focus on higher-value engineering and programming tasks.

- Intelligent feeders and palletizing systems further streamline workflow by minimizing downtime between machining operations.

This continuous automation dramatically improves efficiency and consistency across production runs, helping manufacturers maintain competitive advantages in precision manufacturing.

In addition to improved productivity, automation enhances workplace safety by reducing human involvement in hazardous machining environments. It also enables flexible manufacturing cells where multiple CNC machines and robots operate synergistically, adapting quickly to changing production needs.

The integration of artificial intelligence (AI) and machine learning (ML) into CNC machining systems is revolutionizing precision manufacturing. These technologies imbue machines with the ability to learn from production data and adapt dynamically, enabling more effective and autonomous operations.

- Predictive Maintenance: AI algorithms analyze sensor data (e.g., vibration, temperature) to predict tool and machine wear before failure occurs, minimizing unexpected downtime.

- Adaptive Toolpaths: Machine learning models optimize tool trajectories in real time based on cutting feedback, improving surface finishes and reducing machining time.

- Quality Control: Vision systems powered by AI detect defects invisible to the human eye and generate instant correction feedback.

- Process Optimization: AI recommends cutting speeds, feed rates, and tool changes to maximize tool life and material usage efficiency.

AI also facilitates better data management in CNC machining by analyzing vast amounts of manufacturing data to reveal insights on performance trends, bottlenecks, and process improvements. The synergy of AI with CNC machining enables manufacturers to operate with enhanced precision, reduced waste, and greater reliability, ushering in an era of intelligent machining.

Traditional CNC machining was largely based on three-axis operations. However, multi-axis CNC machines, particularly 5-axis simultaneous machining centers, are now becoming industry standards.

- Ability to machine complex parts in a single setup without repositioning reduces errors and cycle times.

- Enhances surface quality and meets tighter dimensional tolerances.

- Reduces material waste by enabling more precise cuts and efficient toolpaths.

- Supports manufacturing of intricate components with complex curves and angles, essential for aerospace and medical devices.

Multi-axis machines provide flexibility that aligns with the growing demand for custom, complex, and high-precision components. The ability to approach the workpiece from multiple angles allows for greater detail and reduces the need for multiple fixtures, streamlining production.

The combination of CNC machining with additive manufacturing (3D printing) is redefining manufacturing paradigms. Hybrid machines that integrate subtractive and additive processes can fabricate components with complex internal geometries, lightweight structures, and reduced material waste.

- Enables rapid prototyping and highly customized parts.

- Adds material layering and precision machining in seamless workflows.

- Shortens lead times and lowers production costs, especially for low-to-mid volume runs.

This integration is particularly beneficial for industries requiring lightweight but strong structures, such as aerospace and automotive. Hybrid manufacturing also enables repair or augmentation of existing parts, extending their lifecycle and reducing costs associated with complete replacement.

High-speed machining (HSM) is another emerging trend enhancing CNC machining capabilities. By employing spindle speeds as high as 100,000 RPM and minimized cutting forces, HSM improves the efficiency of machining fragile or heat-sensitive materials.

- Achieves faster production without compromising precision.

- Extends tool life by reducing wear and thermal deformation.

- Ideal for mold making, aerospace, and medical component manufacturing.

HSM helps manufacturers reduce cycle times while maintaining exceptional quality standards. With advances in tooling materials and machine rigidity, high-speed machining continues to unlock new possibilities for producing delicate parts with tight tolerance requirements.

The rise of IoT (Internet of Things) technology has introduced real-time monitoring systems to CNC machining facilities. Sensors embedded in CNC machines collect continuous data on machine performance, tool wear, and part quality accessible remotely.

- Enables predictive maintenance, scheduling interventions before failures occur.

- Reduces downtime and maintenance costs.

- Improves traceability and quality documentation.

- Allows managers to oversee multiple machining centers remotely, enhancing operational control.

Real-time connectivity enhances operational efficiency and responsiveness in production environments. This data-driven approach empowers manufacturers to make proactive decisions, optimize machine usage, and ensure consistent quality.

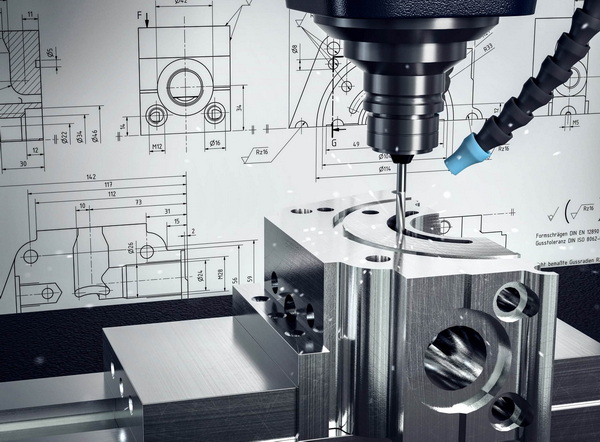

Advanced CAD/CAM software improvements and digital twin technologies are playing an increasingly central role in CNC machining.

- No-code programming platforms simplify CNC programming with drag-and-drop features and automated code generation, lowering skill barriers.

- Simulation software allows virtual machining before physical production, reducing errors and optimizing toolpaths.

- Enhanced software enables better integration across design, manufacturing, and quality assurance workflows.

- Continuous software evolution increases accessibility to CNC machining for new users and enables faster project turnaround times.

Digital twins—virtual replicas of physical machines or production lines—help simulate and optimize machining processes in real time. By identifying inefficiencies or potential problems before actual production, manufacturers save time and costs while improving accuracy.

Sustainability considerations are impacting CNC machining strategies with manufacturers adopting eco-friendly practices.

- Reduced material waste due to the subtractive precision of CNC machining.

- Recycling of scrap materials and energy-efficient machine tool designs.

- Use of advanced control algorithms to minimize energy consumption while maintaining output quality.

Deploying sustainable processes helps companies reduce costs and environmental footprints while meeting growing regulatory standards. Sustainable CNC machining not only benefits the environment but also enhances brand reputation and compliance with international green manufacturing initiatives.

The emergence of on-demand CNC machining platforms allows companies to access machining services without owning equipment.

- AI-powered automatic quoting systems provide instant, accurate cost estimates, eliminating prolonged manual quotation processes.

- On-demand services offer flexibility in scaling production based on immediate business needs.

- This approach reduces overhead and labor costs for brands and manufacturers.

Cloud-based platforms with AI-driven workflows streamline project management from prototype to full-scale production, accelerating time to market and enabling small businesses to leverage high-quality CNC manufacturing without heavy capital investment.

Innovations in materials and tooling are pushing the boundaries of what CNC machining can achieve in precision manufacturing.

- Development of ultra-hard tooling materials such as ceramic and polycrystalline diamond tools enhances cutting performance and longevity.

- Advanced coatings on cutting tools reduce friction and heat buildup, increasing machining speeds and precision.

- Expanded capability to machine new composites and exotic alloys used in aerospace, automotive, and medical sectors with high precision.

These materials and tooling advancements allow CNC machining to handle increasingly demanding applications, expanding its role in cutting-edge manufacturing sectors.

Greater collaboration between design, engineering, and manufacturing teams is being facilitated by digital integration in CNC machining workflows.

- Cloud-based data sharing and version control reduce errors and miscommunication.

- Integration of CNC programming with enterprise resource planning (ERP) systems enhances production scheduling and inventory management.

- Remote CNC operation and monitoring enable decentralized manufacturing options, supporting global supply chains.

Such collaborative workflows improve agility and responsiveness while supporting product customization and complex project demands.

CNC machining is entering an exciting new era marked by the convergence of automation, artificial intelligence, advanced multi-axis capabilities, and hybrid manufacturing techniques. These emerging trends enable manufacturers to achieve unprecedented levels of precision, speed, and efficiency while reducing waste and operational costs. Real-time monitoring, innovative software, enhanced tooling, and sustainability are further reshaping the industry to meet the complex demands of modern production.

As CNC machining technologies continue to evolve, companies that embrace these innovations are poised to gain a competitive advantage in precision manufacturing, delivering high-quality components faster, more reliably, and at optimized costs.

AI enhances CNC machining by optimizing toolpaths, enabling predictive maintenance, and automating quality control, leading to improved precision and reduced downtime.

Multi-axis CNC machining allows complex parts to be produced in fewer setups, reducing errors and cycle time while improving surface finishes and material efficiency.

Hybrid manufacturing combines additive and subtractive methods, enabling intricate, lightweight parts with reduced waste and faster turnaround.

IoT-enabled sensors provide real-time data for predictive maintenance and quality control, reducing downtime and increasing production efficiency.

Manufacturers focus on material recycling, waste reduction, and energy-efficient machinery to lower environmental impact and operational costs.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product