Views: 222 Author: Amanda Publish Time: 2025-08-21 Origin: Site

Content Menu

● Understanding ISO Certifications in CNC Machining

● Why ISO Certifications Matter in CNC Machining Manufacturing

>> 1. Quality Assurance and Product Consistency

>> 2. Enhanced Operational Efficiency

>> 3. Regulatory Compliance and Risk Mitigation

>> 4. Market Competitiveness and Customer Trust

● Key Aspects of Maintaining ISO Certifications in CNC Machining

● Industry-Specific Importance of ISO Certifications in CNC Machining

>> Electric Vehicles and Industrial Automation

● The Role of Technology and Innovation in ISO-Certified CNC Machining

● Building a Quality Culture Around ISO Standards

● Frequently Asked Questions (FAQ)

>> 1. What is the main difference between ISO 9001 and AS9100 in CNC machining?

>> 2. How do ISO certifications improve CNC machining quality?

>> 3. Are ISO certifications mandatory for CNC machining suppliers?

>> 4. What are the benefits of ISO 9001 certification for CNC machine shops?

>> 5. How often must a CNC machining company undergo ISO audits?

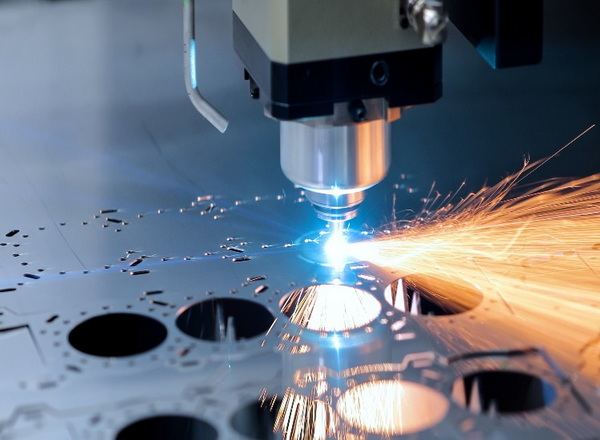

In the rapidly advancing world of precision manufacturing, CNC machining serves as a cornerstone technology, delivering high-accuracy components used across aerospace, medical, automotive, and industrial sectors. To meet ever-increasing demands for quality, safety, traceability, and operational efficiency, ISO certifications have become indispensable. They set internationally recognized standards that ensure manufacturing processes deliver consistent, reliable results. This article explores the critical role of ISO certifications—particularly ISO 9001 and AS9100—in CNC machining manufacturing, illustrating their impact on quality assurance, operational excellence, customer trust, and regulatory compliance.

ISO certifications are developed by the International Organization for Standardization to provide structured guidelines ensuring quality, safety, and efficiency across industries. For CNC machining manufacturing, the key certifications include:

- ISO 9001: Quality Management System (QMS) standard applicable to organizations of all sizes across sectors. It defines requirements to ensure consistent process controls, documentation, preventive action, and continual improvement.

- AS9100: An aerospace-specific quality standard that builds upon ISO 9001, adding requirements for risk management, product safety, traceability, and supplier quality, critical for aerospace, defense, and space industries.

Other relevant standards include ISO 45001 for occupational health and safety, and ISO 14001 for environmental management, each improving different facets of manufacturing operations.

ISO certifications establish a robust foundation for maintaining quality in CNC machining. By documenting and controlling manufacturing procedures, including inspection checkpoints and preventive measures against non-conformance, companies uphold meticulous standards. This means every part produced, whether a tiny medical implant or a large aerospace bracket, meets strict customer specifications with minimal variation, ensuring repeatability and reliability.

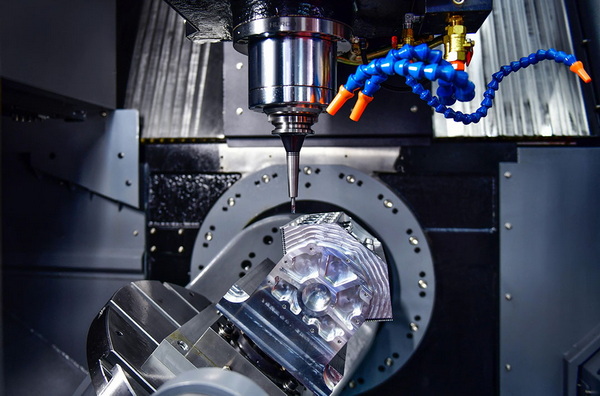

The adherence to ISO standards ensures that every stage of the CNC machining process—from computer-aided design (CAD) programming to the final finishing—follows rigorous protocols. These protocols include machine calibration, tool maintenance, operator qualifications, and final inspection processes. Collectively, they reduce inconsistencies, which can severely impact the functionality and safety of finished components.

ISO standards promote streamlined processes and well-defined workflows. This reduces errors, rework, and scrap, thus optimizing production time and lowering costs. Employees operate under clear guidelines, fostering a culture of quality and continuous improvement. Efficiency gains manifest in faster delivery times and better use of resources.

For a CNC machining shop, efficiency means not only minimizing downtime of expensive machine tools but also reducing material waste and labor inefficiencies. ISO certification requires companies to implement corrective and preventive actions (CAPA) that continually refine processes, thereby raising productivity and profitability.

Many industries, particularly aerospace and medical, mandate ISO certifications to meet regulatory and contractual requirements. Certified companies not only demonstrate adherence to best practices but also proactively manage risks through documented evidence and controlled processes, mitigating potential liabilities associated with product failures or recalls in CNC machining.

With CNC parts often critical to safety or performance, such as those used in aircraft control systems or medical devices, companies must ensure risks are identified, assessed, and minimized. ISO standards demand controlled environments, process capability studies, and traceability that help prevent defects or non-conformance from reaching the customer.

ISO certifications act as a mark of credibility, assuring clients of consistent quality and professionalism. This is a key differentiator in competitive markets, enabling access to high-value sectors with stringent supplier qualifications. Certification signals dedication to excellence and customer satisfaction, fostering long-term business relationships.

In today's global supply chain, many multinational clients prioritize doing business with ISO-certified CNC machining suppliers to guard against potential shipment delays, quality failures, or compliance issues. Holding ISO certification opens doors to sectors and contracts otherwise inaccessible.

- Regular Audits and Inspections: Periodic external and internal audits verify compliance with ISO standards, highlighting areas for continual improvement and ensuring adherence to documented procedures.

- Documented Processes: Comprehensive documentation of manufacturing steps, quality control checks, machine calibrations, and safety measures is mandatory for compliance.

- Training and Education: Ongoing employee training on ISO compliance fosters a quality-focused culture and supports consistent implementation of standards.

Sustaining ISO certification involves continual investment in monitoring quality indicators, calibrating CNC machines to tight tolerances, and ensuring accurate measurement tools are in use. Employee competence evaluations, plus documented approvals for any process changes, are integral parts of the system.

For aerospace manufacturing, ISO 9001 combined with AS9100 certification is critical. These standards ensure:

- Dimensional accuracy within microns

- Full traceability from raw material to finished part

- Risk-based quality controls and product safety protocols

- Compliance with FAA, DoD, and NATO requirements

Typical aerospace components requiring certified machining include flight control mounts, turbine housings, and radar system enclosures. A single flaw could jeopardize safety, making certification mandatory to maintain stringent quality and reliability.

Besides quality, AS9100 emphasizes product safety and counterfeit parts prevention through secure supplier controls and methodical component tracking—key in this sector.

ISO 9001 is essential in medical CNC machining to meet FDA and ISO 13485 regulations. AS9100 is often preferred for complex devices adding traceability and risk management layers. Certified processes ensure patient safety through:

- Precision machining of surgical guides and implantable devices

- Documented batch traceability for audits

- Strict contamination control and burr-free finishes

Patient safety relies on traceability of materials and smooth manufacturing workflows, which certification guarantees through stringent controls, audits, and traceability systems.

In EV production, ISO 9001 certification guarantees quality in critical components like battery trays and powertrain mounts, reinforcing safety and performance in high-volume manufacturing. Aerospace-integrated EV applications may require AS9100 for its heightened standards.

Industrial automation parts—like actuator housings and conveyor system brackets—rely on ISO 9001-certified CNC machining for:

- Precise tolerances ensuring operational reliability

- Consistent surface finishes reducing wear

- Minimized machine downtime via robust quality controls

ISO certification reduces defects and boosts production scalability in these sectors.

Achieving and maintaining ISO certification is increasingly tied with the adoption of advanced technology in CNC machining shops.

- Digital Quality Management Systems (QMS): Automated software platforms support compliance with ISO standards by managing documentation, audit trails, non-conformance reports, and corrective actions more efficiently.

- Machine Learning and AI: Predictive maintenance powered by AI assists in preventing machine breakdowns which could disrupt ISO-compliant operations, helping maintain consistency.

- CNC Software Integration: Connected CAD/CAM systems ensure manufacturing follows precise digital instructions, reducing human error and reinforcing quality control.

- Metrology and Inspection Automation: Coordinate measuring machines (CMM) and vision systems facilitate rapid, accurate inspection, a critical ISO requirement ensuring defect-free parts.

Investing in smart machinery and integrating quality standards into digital workflows empowers CNC shops to uphold ISO certifications with greater precision and efficiency.

ISO certifications demand more than process adherence; they foster a quality-driven culture.

- Employee Empowerment: Training programs educate operators on why ISO matters, improving their commitment to quality.

- Open Communication: A system for logging and addressing quality concerns encourages continuous improvement.

- Management Leadership: Top management's active role in quality planning and review ensures sustained focus on certification goals.

A strong quality culture aligns everyone—from shop floor operators to executives—around delivering CNC machining excellence as defined by ISO norms.

ISO certifications, particularly ISO 9001 and AS9100, play a pivotal role in raising the quality, safety, and efficiency standards of CNC machining manufacturing. They enable companies to produce highly precise, reliable components that meet the demanding requirements of aerospace, medical, automotive, and industrial clients. With increased market access, enhanced operational outcomes, and stronger customer trust, maintaining ISO certifications is not optional but essential for CNC machining businesses aiming for excellence and competitive advantage in today's global marketplace.

ISO 9001 is a general quality management standard applicable to various industries focusing on overall process consistency. AS9100 builds on ISO 9001, adding aerospace-specific requirements including risk management, product safety, and traceability essential for high-risk sectors like aerospace and defense.

They establish documented processes, regular audits, and preventive controls that reduce variability and defects, ensuring every part meets precise specifications consistently.

While not legally mandatory in all regions, ISO certifications are often required or highly preferred by customers in regulated industries such as aerospace, medical, and automotive to qualify suppliers and ensure compliance.

Benefits include improved quality control, operational efficiency, customer trust, regulatory compliance, reduced errors, and enhanced employee morale.

Typically, companies undergo annual surveillance audits and a more comprehensive recertification audit every three years to maintain ISO certifications and ensure ongoing compliance.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal