Views: 222 Author: Amanda Publish Time: 2025-10-04 Origin: Site

Content Menu

● Understanding Injection Molding

● Key Design Practices for Injection Molding Efficiency

>> Incorporate Ribs for Strength

>> Simplify Geometry and Avoid Undercuts

>> Design for Manufacturability (DFM)

>> Optimize Material Flow with Mold Flow Analysis

>> Coring for Material Efficiency

>> Material Selection Strategy

● Process Optimization Techniques

● Advanced Technologies in Injection Molding

● Sustainable Practices in Injection Molding

>> 1. What is injection molding and how does it work?

>> 2. How can uniform wall thickness improve injection molding?

>> 3. Why are draft angles important in injection molded parts?

>> 4. What role does Design for Manufacturability (DFM) play?

>> 5. How does mold flow analysis enhance mold design?

Injection molding is a cornerstone manufacturing process used worldwide for producing precise, complex plastic parts with high repeatability. To harness the full potential of injection molding, product designs must be carefully optimized to enhance efficiency, reduce costs, and maintain superior part quality. This article provides an in-depth exploration of best practices for designing products that achieve maximum injection molding efficiency.

The following guide covers critical design considerations such as wall thickness, draft angles, ribs, material choice, mold design, and process optimizations. It also addresses advanced technologies and sustainability in injection molding. These insights enable designers, engineers, and manufacturers to create injection molded parts that are manufacturable, high-quality, and cost-effective.

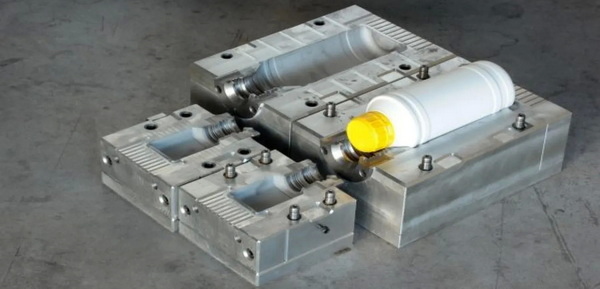

Injection molding involves melting plastic pellets and injecting the molten polymer under high pressure into a mold cavity shaped like the final product. The part cools and solidifies as it takes the shape of the mold. Injection molding machines vary in type—hydraulic, electric, or hybrid—and are chosen based on project requirements for precision, speed, and size.

Selecting the right polymer is fundamental, balancing mechanical properties, thermal behavior, aesthetics, and cost. Common thermoplastics include polyethylene (PE), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). The interplay between design and material choice largely determines production efficiency and the quality of the final product.

One of the most critical design principles is maintaining uniform wall thickness throughout the part. Uniform thickness ensures consistent cooling rates, which substantially reduces common defects such as warping, shrinkage, sink marks, and internal stresses.

If varying thicknesses are unavoidable, transitions should be gradual and smooth using chamfers or fillets to promote uniform material flow within the mold and minimize flow disturbances.

To enhance strength without increasing wall thickness, ribs are an excellent solution. Ribs are thin, raised structural features that provide reinforcement, enabling parts to maintain rigidity while avoiding thick sections that would increase cooling time and material consumption.

Design ribs to be about 40-60% of the adjacent wall thickness and ensure they have appropriate height and draft. Avoid sharp transitions by filleting rib bases to reduce stress concentrations. Properly spaced ribs also help maintain even material flow.

Draft angles are slight tapers on vertical walls that facilitate easy ejection of the part from the mold. Typical draft angles range from 1 to 2 degrees on vertical faces. Consistent draft reduces sticking, reduces mold wear, and speeds up the ejection cycle.

When designing parts with deep features or coring, increased draft angles may be necessary to prevent deformation and ease mold removal.

Complex geometries with undercuts, deep grooves, and side actions complicate mold design, increase tooling cost, and prolong cycle times. Simplifying geometry by minimizing undercuts or designing self-ejecting features improves moldability and reduces manufacturing complexity.

Where essential, undercuts can be handled with side-actions or collapsible cores, but these add cost and operational complexity.

Engaging early with injection molding experts for DFM evaluations leads to optimized part and mold designs that reduce production risks and costs. DFM involves validating part geometry, wall thickness, draft, gate location, cooling lines, and venting strategies.

Optimized gating and runner systems improve fill balance and minimize pressure requirements. Hot runner molds reduce material waste and maintain melt temperature, enhancing cycle times and quality.

Mold flow simulation software predicts the behavior of molten plastic in the cavity, highlighting issues such as air traps, weld lines, or potential short shots. Utilizing these tools before mold fabrication helps refine designs to ensure complete fill and defect-free parts, ultimately reducing costly tooling changes.

Coring involves hollowing out thick sections to control weight and minimize sink marks while maintaining structural integrity. Smooth transitions between cored and solid sections must be designed carefully with fillets to avoid stress concentrations and flow disruptions.

Adding radii and fillets to internal and external corners improves flow, reduces stress concentration, and enhances aesthetics. Large fillets prevent sharp angles where material may stagnate, allowing for better fill and reducing the risk of cracks or molded-in stresses.

Selecting the right plastic material early impacts wall thickness design, cycle time, part strength, and finishing processes. High-flow materials allow thinner walls and finer details, while engineering-grade plastics might require thicker sections for strength.

Material properties such as shrinkage rates, thermal conductivity, and flow characteristics must be accounted for in the mold and part design.

Accurate control and fine-tuning of injection molding process parameters, including injection speed, pressure, mold temperature, and cooling time, are crucial to balancing efficiency and part quality. Automation and monitoring systems facilitate maintaining ideal conditions, reducing variability and rejects.

Regular mold maintenance and condition monitoring prevent unplanned downtime, ensuring stable manufacturing efficiency.

- Computer-Aided Engineering (CAE): Virtual simulations optimize mold designs and process parameters before production.

- Automation: Robotics and automated systems improve part handling, cycle consistency, and operational safety.

- 3D Printing: Enables rapid prototyping and manufacturing of complex inserts or tooling components, accelerating development and customization.

Environmental concerns drive adoption of recyclable and bioplastic materials and energy-efficient machines. Waste reduction programs and closed-loop recycling systems are increasingly integrated to minimize environmental footprints in injection molding.

Efficient injection molding design integrates uniform wall thickness, draft angles, ribs, simplified geometry, DFM collaboration, and material optimization, supported by mold flow analysis and process control. Taking a holistic approach from design through manufacturing ensures faster cycles, reduced costs, superior quality, and sustainable production. Advanced engineering tools and sustainable strategies further enhance efficiency and competitiveness in injection molding.

Optimizing injection molding from the early design phase is vital for manufacturers seeking success in a highly demanding, cost-sensitive market.

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity, cooled, and expelled as a finished part. It enables precise, repeatable mass production of complex plastic components.

Maintaining uniform wall thickness ensures even cooling and material flow, reducing defects like warping, sink marks, and internal stresses. It also lowers cycle times and material usage.

Draft angles facilitate easy removal of parts from molds, minimizing sticking, mold wear, and damage during ejection. Typical drafts are between 1° and 2°, improving production speed and quality.

DFM involves designing parts with manufacturing efficiency and cost in mind by optimizing geometry, wall thickness, gating, and mold features. It prevents costly revisions and shortens lead times.

Mold flow analysis simulates plastic flow within the mold, identifying potential defects and flow issues before tooling is made. It helps optimize gate placement, cooling, and part geometry for defect-free production.

[1](https://www.crescentind.com/blog/how-to-ensure-high-quality-injection-molding-6-best-practices)

[2](https://www.protolabs.com/resources/guides-and-trend-reports/designing-for-moldability-fundamental-elements/)

[3](https://www.goldengatemolders.com/post/injection-molding-101-a-comprehensive-guide-for-newcomers)

[4](https://jiga.io/injection-molding/design-for-injection-molding-guide/)

[5](https://www.hubs.com/guides/injection-molding/)

[6](https://xometry.pro/wp-content/uploads/2025/03/EN-eBook_-Injection-Molding-Design-Guide.pdf)

[7](https://www.fictiv.com/wp-content/uploads/2021/07/IM-Design-Guide-ebook.pdf)

[8](https://geomiq.com/injection-moulding-design-guide/)

[9](https://xometry.eu/en/design-tips-for-injection-moulding/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product