Views: 222 Author: Amanda Publish Time: 2025-10-06 Origin: Site

Content Menu

● Understanding Injection Molding for Complex Parts

● Critical Design Strategies for Complex Injection Molding

>> Incorporating Functional Features

>> Text, Logos, and Surface Detail

● Advanced Mold Technologies for Complex Parts

>> Core Pins and Collapsible Cores

>> Overmolding

● Material Selection for Complex Injection Molded Parts

● Injection Molding Process Considerations

>> Cooling

>> Ejection

● Integrating Complex Features into Core and Cavity Design

>> Texture and Logo Integration

● Best Practices for Successful Complex Injection Molding

● Frequently Asked Questions (FAQs)

>> 1. Can injection molding create complex shapes like undercuts and internal threads?

>> 2. What materials are suitable for complex injection molded parts?

>> 3. How does overmolding improve product functionality?

>> 4. Why is draft angle important in complex injection molding?

>> 5. How does automation benefit injection molding of complex parts?

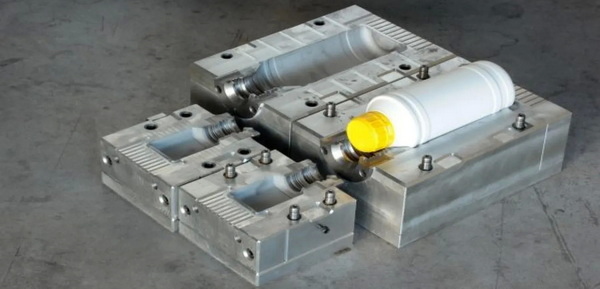

Injection molding is a fundamental manufacturing process widely used to produce plastic parts efficiently and cost-effectively. When addressing complex part designs featuring intricate geometries, thin walls, undercuts, and multifunctional features, specialized injection molding techniques are critical for success. This comprehensive article explores the best techniques for molding complex parts, focusing on design principles, advanced molding technologies, material considerations, and industry best practices to help manufacturers and designers optimize outcomes.

At its core, injection molding involves injecting molten plastic into a mold cavity that shapes the part. For complex parts, traditional molding methods can fall short because challenges such as warping, sink marks, difficulty in ejection, and incomplete filling arise. Advanced mold designs and process controls are essential to overcome these hurdles and achieve high precision and repeatability.

Design is the foundation for successful injection molding of complex components. Implementing best practices early improves manufacturability and quality:

Maintaining uniform wall thickness minimizes differential cooling and shrinkage, which causes warping and sink marks. Designers should aim for wall thickness consistent throughout the part or transitioning smoothly. Thickness should typically fall within the recommended range for the chosen resin type to balance strength and manufacturability.

Applying appropriate draft angles (usually 1 to 2 degrees) on vertical surfaces facilitates easier ejection from molds without damaging delicate features. For very thin or tall vertical parts, even slight draft angles significantly reduce defects.

Complex parts often have integrated clips, snap fits, ribs, bosses, or living hinges to enhance product functionality while minimizing assembly. Designing these with proper draft angles, thickness, and transitions ensures smooth mold filling and easy part release.

Embedding embossed or debossed text and logos directly into molds reduces post-processing. Ensuring these features are integrated with the right draft angles and modest depth avoids warping and brittleness. Smooth mold surface finishes are essential for crisp fine details.

Advanced tooling enables the production of highly intricate geometries beyond conventional mold capabilities.

Sliding shutoff mechanisms in molds block material flow selectively, allowing features like undercuts or snap fits to be molded in a single shot. These sliding components retract during part ejection, improving mold complexity handling and cycle efficiency.

Side-action cams move perpendicular to the mold opening direction to form undercuts, recesses, or embedded features that standard molds cannot create. They ensure precision while facilitating part release.

Core pins create through-holes, channels, or internal threads by protruding into the cavity space. Collapsible cores or unscrewing core elements form screw threads or complex internal geometries and collapse or retract for easy ejection.

Overmolding combines two or more materials in sequential molding steps to produce multi-material parts, such as a soft grip over a rigid core. It improves ergonomics, aesthetics, and product functionality across medical, automotive, and electronics sectors.

Insert molding integrates metal or other component inserts during molding, embedding them permanently in plastic parts. This enhances mechanical strength and electrical connectivity, useful in hybrid material applications.

Stack molding uses multiple mold layers stacked vertically to produce complex multi-level parts in fewer cycles, increasing throughput and reducing tooling costs.

Material choice influences mechanical performance, surface finish, and processability.

- Thermoplastics like ABS, polycarbonate, nylon, and polypropylene offer strong, versatile options for complex geometries.

- Thermoplastic elastomers (TPE) allow flexible, comfortable features in overmolded regions.

- High-performance resins such as PEEK or PPS provide durability and heat resistance but raise costs.

- Considerations include flow characteristics, cooling rates, shrinkage, and compatibility with mold design constraints.

Achieving quality in complex injection molding requires precise control over several process parameters:

Molds are cleaned, lubricated, and preheated to optimize plastic flow and prevent defects. Maintenance ensures longevity and consistent quality.

Plastic pellets are melted and injected at controlled temperatures and pressures to fill cavities completely without premature cooling or degradation.

Critical for dimensional accuracy, cooling times depend on part thickness and material. Proper cooling channel design accelerates cycle times and prevents warping.

Ejector pins, plates, and mechanisms remove parts gently from molds, considering part features. Side actions and collapsible cores assist in ejecting complex geometries.

Post-molding trimming removes excess flash from gates and runners. Additional machining, assembly, painting, or coating may follow depending on part requirements.

The mold's core (male side) and cavity (female side) define the internal and external part geometries and must be designed carefully for complex parts:

These reinforcing features add strength with minimal weight. They require proper draft angles and wall thickness transitions to avoid defects.

Threads molded in during production reduce assembly steps. Collapsible or unscrewing cores allow thread formation and release inside molds.

Thin flexible sections integrated into parts for hinged movement. Uniform thickness and rapid cooling prevent weak points and failures.

Core pins and sliding shutoffs form precise holes for assembly or fluid flow. Proper alignment and draft prevent part damage during release.

High polish and controlled draft ensure crisp fine details while avoiding defects from thick or sharp features.

- Design for Manufacturability (DFM): Simplify part complexity while maintaining function to reduce costs and improve yield.

- Prototype and Testing: Use rapid prototyping to validate mold design and fit before full-scale production.

- Advanced Tooling: Incorporate movable mold components like side actions and slides to enable intricate features.

- Process Automation: Employ sensors and AI-driven monitoring to optimize cycle times and maintain consistent quality.

- Quality Control: Perform dimensional inspections, visual checks, and material testing regularly.

Complex part designs require forward-thinking injection molding approaches integrating advanced mold toolings, such as sliding shutoffs, side-action cams, and core pins, with strategic design choices including uniform wall thickness, adequate draft, and functional integration. Material selection tailored to performance and manufacturability, along with controlled injection processes, ensures high-quality, repeatable parts that meet demanding industry needs. Employing these best practices supports scalability, cost efficiency, and innovation in sectors from automotive to medical devices.

Yes, with advanced molding techniques such as sliding shutoffs, side-action cams, and collapsible cores, injection molding can produce intricate shapes including undercuts and molded-in threads.

Common materials include ABS, polycarbonate, and polypropylene for rigidity, and thermoplastic elastomers for flexible areas. Selection depends on mechanical, thermal, and aesthetic requirements.

Overmolding allows combining different materials in one part, such as a soft-touch grip over a rigid structure, enhancing ergonomics and design versatility.

Draft angles assist in the smooth ejection of parts from molds and prevent damage to delicate features and defects caused by part sticking.

Automation and AI enable precise control of parameters, reduce defects, shorten cycle times, and ensure consistent high-quality production.

[1](https://protoshopinc.com/blog/designing-prototype-molds-for-complex-parts/)

[2](https://www.lernermoldedplastics.com/master-guide-large-molded-parts-using-injection-molding/)

[3](https://geomiq.com/injection-moulding-guide/)

[4](https://www.protolabs.com/resources/guides-and-trend-reports/designing-for-moldability-fundamental-elements/)

[5](https://www.hubs.com/guides/injection-molding/)

[6](https://xometry.pro/wp-content/uploads/2025/03/EN-eBook_-Injection-Molding-Design-Guide.pdf)

[7](https://www.fictiv.com/articles/injection-molding-tolerances-an-in-depth-look)

[8](https://firstmold.com/guides/injection-mold-components/)

[9](https://jiga.io/injection-molding/injection-mold-tooling-comprehensive-guide/)

[10](https://www.crescentind.com/blog/how-injection-molding-makes-complex-plastic-parts)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal