Views: 222 Author: Amanda Publish Time: 2025-07-15 Origin: Site

Content Menu

>> Key Techniques in Rapid Prototyping

● The Cost-Saving Benefits of Rapid Prototyping

>> Accelerated Product Development

>> Lower Labor and Tooling Costs

>> Enhanced Design Flexibility

>> Improved Communication and Collaboration

● How Rapid Prototyping Techniques Reduce Costs Across Industries

● Step-by-Step Guide: Implementing Rapid Prototyping to Cut Costs

>> Step 1: Define Project Requirements

>> Step 2: Choose the Right Rapid Prototyping Technique

>> Step 3: Create a Digital Model

>> Step 4: Produce the Prototype

>> Step 6: Finalize Design for Production

● Case Study: Cost Reduction with Rapid Prototyping

● Visualizing the Rapid Prototyping Workflow

● Integrating Rapid Prototyping with CNC Machining and Sheet Metal Fabrication

● The Role of 3D Printing in Cost Reduction

● Tips for Maximizing Cost Savings with Rapid Prototyping

● Common Challenges and Solutions

>> Scaling from Prototype to Production

>> Cost of High-Quality Prototypes

>> Intellectual Property Protection

● FAQ

>> 1. What is Rapid Prototyping and how does it help reduce costs?

>> 2. Which industries benefit the most from Rapid Prototyping?

>> 3. Can Rapid Prototyping be used for mass production?

>> 4. How does Rapid Prototyping improve product quality?

>> 5. What are the main challenges when adopting Rapid Prototyping?

In today's highly competitive manufacturing landscape, companies are under constant pressure to deliver innovative products faster and at lower costs. Rapid Prototyping has emerged as a game-changing approach, enabling businesses to streamline product development, minimize errors, and significantly reduce expenses. This article explores how leveraging Rapid Prototyping techniques can help organizations cut costs while maintaining high standards of quality and efficiency.

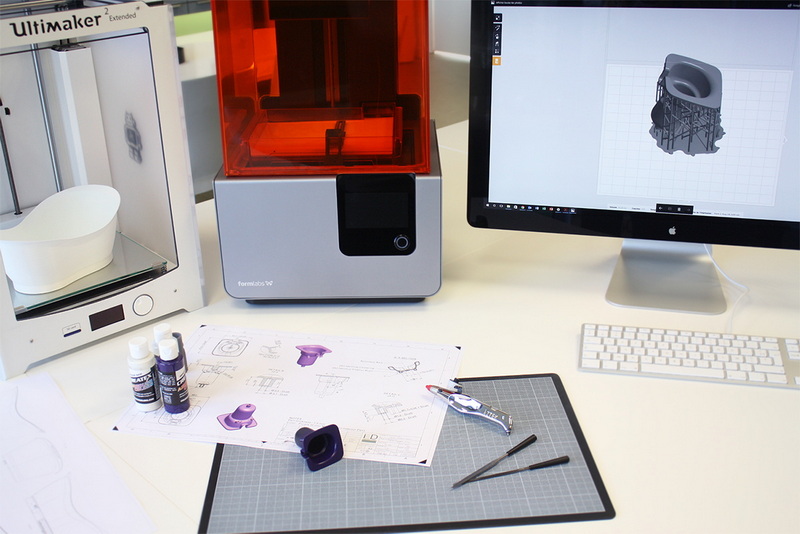

Rapid Prototyping refers to a group of advanced manufacturing processes used to quickly fabricate a scale model or functional part using three-dimensional computer-aided design (CAD) data. Unlike traditional manufacturing methods, Rapid Prototyping allows for the creation of prototypes in a fraction of the time, enabling faster iteration and validation of product designs.

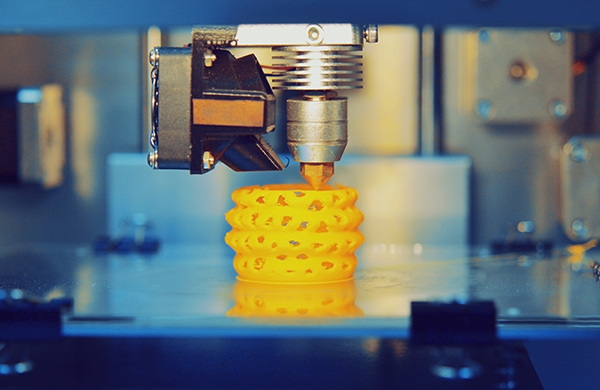

- 3D Printing (Additive Manufacturing): Builds parts layer by layer from materials such as plastics, resins, or metals, allowing for complex geometries and rapid turnaround.

- CNC Machining: A subtractive process that uses computer-controlled tools to carve parts from solid blocks of material, offering high precision and excellent surface finish.

- Sheet Metal Fabrication: Involves cutting, bending, and assembling thin metal sheets into desired shapes, commonly used for enclosures and structural components.

- Vacuum Casting: A method to produce small batches of parts with properties similar to injection-molded components, ideal for functional testing.

- Injection Molding for Prototyping: Utilizes molds to create prototypes that closely mimic mass-produced parts, useful for validating production tooling and design.

One of the most significant advantages of Rapid Prototyping is the speed at which prototypes can be produced. Traditional prototyping methods often take weeks or months, but Rapid Prototyping can deliver physical models in days or even hours. This acceleration enables companies to test product concepts earlier, identify design flaws quickly, and make necessary adjustments without delaying the overall project timeline. Faster development cycles translate directly into reduced labor costs and earlier market entry, which can be critical for gaining competitive advantage.

Traditional manufacturing processes, especially subtractive methods, generate considerable material waste as excess material is cut away. Rapid Prototyping, particularly additive manufacturing like 3D printing, uses only the material required to build the part. This precision reduces raw material consumption, lowering costs and minimizing environmental impact. Additionally, the ability to produce prototypes without the need for expensive molds or tooling further decreases resource expenditure.

Conventional prototyping often requires skilled labor to create molds, jigs, or fixtures, which can be costly and time-consuming. Rapid Prototyping eliminates or greatly reduces the need for such tooling in early development stages. This reduction in manual labor and tooling investment lowers upfront costs and allows resources to be allocated more efficiently. Moreover, because Rapid Prototyping techniques are largely automated, they reduce human error and improve consistency.

Rapid Prototyping empowers designers to experiment with multiple iterations quickly and cost-effectively. If a design requires modification, changes can be made digitally in the CAD model and a new prototype produced without the need for new tooling. This flexibility encourages innovation and ensures that the final product is refined and optimized before committing to mass production, thereby avoiding costly redesigns and production delays.

Physical prototypes serve as tangible references that facilitate clearer communication among design teams, engineers, clients, and stakeholders. This shared understanding helps prevent misinterpretations and aligns expectations early in the process. By catching potential issues through hands-on evaluation, teams can collaborate more effectively, reducing the risk of costly errors downstream.

In the automotive sector, Rapid Prototyping is essential for testing component fit, function, and aesthetics before committing to expensive tooling and assembly line changes. Prototypes can be produced to validate ergonomics, aerodynamics, and mechanical performance. This early validation reduces the risk of costly recalls and retooling, ensuring smoother production ramp-up and better product reliability.

Aerospace manufacturers demand extremely high precision and reliability. Rapid Prototyping allows for the creation of accurate, functional parts that can be tested under real-world conditions. This capability helps detect design flaws early, reduces the need for expensive physical testing, and accelerates certification processes. The ability to produce lightweight, complex geometries also supports innovation in fuel efficiency and performance.

The fast-paced consumer electronics market benefits immensely from Rapid Prototyping. Designers can quickly produce enclosures, connectors, and internal components for testing form, fit, and function. Rapid iteration shortens product development cycles, enabling companies to launch new devices faster and respond to market trends more effectively. This agility reduces inventory costs and minimizes the risk of product obsolescence.

In the medical field, Rapid Prototyping facilitates the development of custom implants, surgical tools, and diagnostic devices. Prototypes can be tailored to patient-specific anatomy, improving outcomes and reducing the need for costly revisions. Additionally, the ability to quickly produce and test new designs supports regulatory compliance and accelerates time-to-market.

Start by clearly defining the objectives, specifications, and performance criteria for your prototype. Understanding the functional requirements and constraints ensures that the prototype focuses on essential features, avoiding unnecessary complexity and expense.

Select the most suitable prototyping method based on the intended use, material properties, and design complexity. For example, 3D printing excels at producing intricate shapes, CNC machining delivers high precision and durability, while sheet metal fabrication is ideal for structural components and enclosures.

Develop a detailed 3D CAD model of your product. This digital representation is the foundation for all Rapid Prototyping processes and allows for easy modifications and simulations before physical production.

Fabricate the prototype using the chosen Rapid Prototyping technique. This step is typically faster and less expensive than traditional methods, enabling rapid turnaround and early testing.

Evaluate the prototype for fit, function, durability, and aesthetics. Use feedback to refine the design and produce updated prototypes as needed. Rapid iteration helps identify and resolve issues before finalizing the design.

Once the prototype meets all requirements, prepare the design for mass production. This stage may involve creating production tooling or molds, but with the confidence that costly errors have been minimized through thorough prototyping.

A global electronics manufacturer sought to develop a new smartphone case. By leveraging Rapid Prototyping, the company produced multiple design iterations within days, testing for durability, ergonomics, and aesthetics. This process eliminated the need for expensive molds during early development and allowed for quick adjustments based on user feedback. Ultimately, the company reduced development time by half and cut prototyping costs by more than 60%, enabling a faster product launch and higher customer satisfaction.

The typical workflow begins with concept design, followed by CAD modeling. The digital model is then used to produce a physical prototype via 3D printing, CNC machining, or other techniques. After testing and evaluation, the design is iterated as necessary. Once finalized, the design transitions to mass production. This streamlined process minimizes delays and reduces the risk of costly errors.

Combining Rapid Prototyping with CNC machining and sheet metal fabrication unlocks additional cost-saving opportunities. For example, initial prototypes can be 3D printed for fast evaluation of complex shapes, while final functional prototypes or small batch production parts are produced using CNC machining for superior strength and finish. Sheet metal fabrication complements these techniques by enabling the creation of durable enclosures and structural elements.

- Faster Transition from Prototype to Production: Smooth handoff between prototyping and manufacturing reduces lead times.

- Optimized Material Usage: Each technique is used where it is most cost-effective.

- Improved Product Quality: Combining methods ensures prototypes meet both design and functional requirements.

3D Printing is central to Rapid Prototyping's cost-saving potential. It enables the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing. By building parts layer by layer, 3D printing uses only the necessary material, reducing waste. It also allows for rapid design changes without additional tooling costs, making it ideal for iterative development.

3D printing materials have expanded beyond plastics to include metals, ceramics, and composites, broadening its applications. This versatility supports functional testing and even low-volume production, further driving down costs.

- Start Prototyping Early: Address design flaws before they become expensive to fix.

- Iterate Quickly: Use Rapid Prototyping to test multiple design variations in parallel.

- Leverage Digital Tools: Utilize advanced CAD and simulation software to optimize designs before physical prototyping.

- Partner with Experienced Providers: Collaborate with manufacturers specializing in Rapid Prototyping to ensure quality and efficiency.

- Consider Material Selection Carefully: Choose materials that balance cost, functionality, and prototype fidelity.

Some Rapid Prototyping methods may not offer the exact mechanical or thermal properties required for final products. To overcome this, select techniques like CNC machining or vacuum casting for functional prototypes that better mimic production materials.

Transitioning from prototype to mass production can be challenging due to differences in manufacturing processes. Early involvement of production engineers and use of prototype-friendly production methods can smooth this transition.

While Rapid Prototyping reduces many costs, high-fidelity prototypes can still be expensive. Prioritize prototyping efforts on critical components and use lower-cost methods for less critical parts.

Highly complex designs may require specialized Rapid Prototyping equipment or hybrid manufacturing approaches. Collaborate with experts to select the best approach for your project.

Sharing digital files for prototyping can raise IP concerns. Use secure communication channels and work with trusted partners to safeguard proprietary information.

Rapid Prototyping has revolutionized product development by enabling faster, more flexible, and cost-effective design iterations. By reducing material waste, lowering labor and tooling costs, and improving communication, Rapid Prototyping techniques help companies bring better products to market more efficiently. Integrating Rapid Prototyping with CNC machining and sheet metal fabrication further enhances these benefits. Whether you operate in automotive, aerospace, consumer electronics, or medical devices, adopting Rapid Prototyping is a proven strategy to reduce costs and accelerate innovation.

Rapid Prototyping is a set of manufacturing techniques that quickly produce physical models from digital designs. It reduces costs by minimizing material waste, eliminating the need for expensive tooling, and allowing for rapid design iterations.

Industries such as automotive, aerospace, consumer electronics, medical devices, and industrial equipment benefit significantly due to the need for fast development cycles and precision.

While primarily used for prototyping and low-volume production, some advanced Rapid Prototyping techniques can be scaled for small batch manufacturing, especially when combined with CNC machining and sheet metal fabrication.

By enabling multiple design iterations and thorough testing before mass production, Rapid Prototyping ensures that only the best designs move forward, reducing defects and improving overall product quality.

The main challenges include selecting the right technique for your needs, understanding material limitations, and ensuring a smooth transition from prototype to mass production. Partnering with experienced providers can help overcome these challenges.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal