Views: 222 Author: Amanda Publish Time: 2025-09-10 Origin: Site

Content Menu

● What is Sheet Metal Fabrication?

● Commonly Used Materials in Sheet Metal Fabrication

>> Mild Steel (Cold Rolled Steel)

>> Stainless Steel (Grades 304 and 316)

>> Aluminum (Alloys 5052, 6061, 5083)

>> Copper

>> Brass

>> Titanium

>> Bronze

● Fabrication Techniques and Material Suitability

● Industry Applications by Material

● Frequently Asked Questions (FAQ)

>> 1. What factors should I consider when selecting materials for sheet metal fabrication?

>> 2. Which material is most suitable for outdoor sheet metal fabrication projects?

>> 3. Can all metals be used in sheet metal fabrication?

>> 4. What advantages does stainless steel have over mild steel in sheet metal fabrication?

>> 5. What are common surface finishes used in sheet metal fabrication, and why are they important?

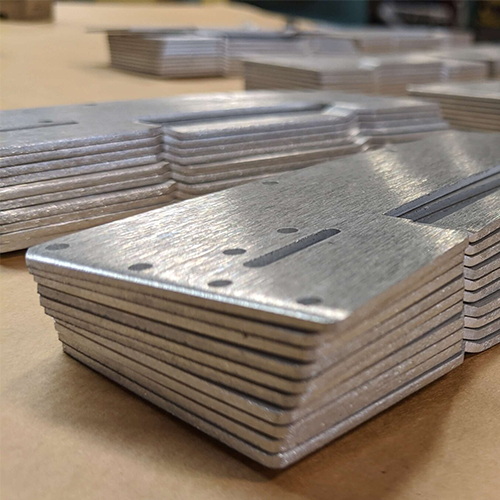

Sheet metal fabrication is a vital manufacturing process that transforms flat sheets of metal into precise parts and products through cutting, bending, welding, and assembling. It is highly valued for its versatility, durability, and capability to produce complex custom components across diverse industries such as automotive, aerospace, electronics, construction, and medical devices. A thorough understanding of the best materials used in Sheet Metal Fabrication and their specific applications can significantly improve product quality and cost efficiency.

This article provides an in-depth exploration of the most popular materials utilized in sheet metal fabrication, highlighting their material properties, key advantages, and typical applications. It also discusses advanced fabrication techniques that enhance these materials' performance and finishes while integrating related visual and video resources to enrich comprehension.

Sheet metal fabrication involves cutting, shaping, and assembling thin metal sheets into desired shapes and components. This process uses various methods, including laser cutting, water jet cutting, punching, bending, and welding, to deliver precise, repeatable, and scalable parts. It is favored for offering a balance of strength, customization, and cost-effectiveness, especially for industries requiring high-performance yet lightweight structures.

Sheet metal fabrication provides critical solutions to manufacturing needs ranging from small electronic enclosures to large industrial frameworks. It permits the production of complex geometries while maintaining tight tolerances and reducing material waste.

Choosing the right material for sheet metal fabrication depends on factors such as mechanical strength, corrosion resistance, machinability, weight, cost, and the environmental conditions in which the final product will operate.

Mild steel is the most cost-effective and widely used sheet metal in manufacturing. It offers excellent strength—typically between 250 and 400 MPa—and good formability. Mild steel is easy to weld and machine, making it ideal for structural parts and industrial equipment where high toughness and moderate corrosion resistance (with coatings) are needed.

- Applications: Machinery parts, support frames, brackets, industrial enclosures

- Pros: Low cost, good strength, easy to coat and weld

- Cons: Susceptible to rust when uncoated

Stainless steel is prized for its superior corrosion resistance, mechanical strength, and clean, attractive finish. It contains chromium which forms a passive oxide layer that protects the metal from rusting. Grade 304 is versatile for general use, while type 316 includes molybdenum for enhanced resistance to chlorides, making it ideal for marine and chemical environments.

- Applications: Medical devices, food processing equipment, architectural panels, chemical plant components

- Pros: Excellent corrosion resistance, strength, durable finish

- Cons: Higher cost and greater machining difficulty compared to mild steel

Aluminum stands out for its lightweight, corrosion resistance, and excellent thermal and electrical conductivity. It has an oxide layer that provides rust-free surface protection. Different alloys serve various needs: 5052 and 3003 are formable and weldable, suitable for marine and automotive parts; 6061, stronger but less formable, is used in structural and machined parts; 5083 is highly corrosion-resistant for marine applications.

- Applications: Aerospace components, automotive body parts, electronic housings, roofing, heat sinks

- Pros: Lightweight, corrosion-resistant, good strength-to-weight ratio

- Cons: Softer than steel, prone to dents, requires careful handling

Copper is a preferred material for applications requiring high electrical and thermal conductivity. Its ductility and corrosion resistance make it ideal for electrical wiring and heat exchangers. Over time, copper develops a protective patina that enhances corrosion resistance, especially in architectural uses.

- Applications: Electrical contacts, circuit boards, roofing, heat exchangers

- Pros: Superior conductivity, ductile, corrosion-resistant

- Cons: High cost, softer metal

Brass is an alloy of copper and zinc that blends strength with corrosion resistance and low friction. It is easy to machine and form, making it ideal for decorative and mechanical parts such as fittings, musical instruments, and wear-resistant components.

- Applications: Mechanical components, decorative panels, musical instruments

- Pros: Low friction, corrosion resistant, good machinability

- Cons: More costly than steel

Galvanized steel consists of mild steel coated with a layer of zinc to prevent rusting. It combines the strength and cost benefits of mild steel with enhanced protection against oxidation, especially in outdoor or humid conditions.

- Applications: Roofing, automotive parts, outdoor enclosures, household appliances

- Pros: Corrosion resistance, stronger than plain mild steel, cost-effective

- Cons: Zinc coating may wear over time requiring maintenance

Titanium offers an unparalleled strength-to-weight ratio and exceptional corrosion resistance, especially in extreme environments. Its biocompatibility also makes it indispensable in medical implants. However, it is more expensive and challenging to work with compared to other metals.

- Applications: Aerospace parts, medical implants, advanced automotive components

- Pros: Very strong, lightweight, corrosion resistant

- Cons: High cost, requires specialized fabrication techniques

Bronze, primarily an alloy of copper and tin, is valued for its wear resistance and attractive patina. It is widely used in marine hardware, bearings, bushings, and artistic sculptures.

- Applications: Bearings, marine equipment, architectural features

- Pros: Wear resistant, corrosion resistant in marine environments

- Cons: Not as widely available as other metals, heavier

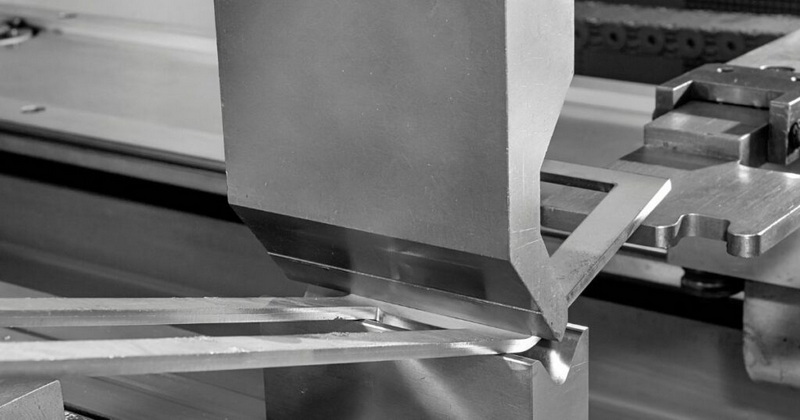

Modern sheet metal fabrication employs several advanced techniques that complement specific material properties, ensuring optimal performance of the final product:

- Laser Cutting: Offers precise, clean cuts with minimal heat distortion, excellent for stainless steel and aluminum.

- Waterjet Cutting: Cold cutting technique suitable for a wide range of metals including titanium without affecting material properties.

- Punching and Stamping: Useful for high-volume production of thin sheet metals such as brass and mild steels.

- Bending and Forming: CNC machines enable accurate shaping of complex angles without compromising structural integrity.

- Welding: Processes like TIG and MIG welding provide strong joints in stainless steel and aluminum assemblies.

- Surface Treatments: Anodizing aluminum enhances corrosion resistance and appearance; powder coatings protect mild and stainless steels; galvanizing prevents rust in mild steel.

- Automotive: Mild steel and aluminum are predominant, offering a balance of strength and lightweight benefits needed for chassis, body panels, and engine parts.

- Aerospace: Aluminum alloys and titanium dominate due to their low weight, strength, and corrosion resistance in demanding environments.

- Construction: Galvanized steel and aluminum offer protection and aesthetic value in roofing, cladding, and structural components.

- Electronics: Copper and aluminum are used extensively for enclosures, heat sinks, and electrical connectors due to their conductivity.

- Medical and Food Equipment: Stainless steel is preferred for its hygienic properties and resistance to corrosion and staining.

Selecting the best materials for sheet metal fabrication requires balancing mechanical properties, corrosion resistance, weight considerations, cost, and the environment in which the product will function. Mild steel remains a cost-effective choice for many structural components, while stainless steel ensures longevity and cleanliness in harsh or hygienic settings. Aluminum alloys offer lightweight solutions with good strength and corrosion resistance for aerospace and automotive sectors. Copper and brass cater to applications demanding excellent electrical and thermal conductivity or decorative finishes. The high-performance titanium serves niche industries where strength and corrosion resistance justify the cost.

Advancements in fabrication methods and finishing techniques continue to enhance the potential of these metals, enabling manufacturers to build durable, precise, and aesthetically pleasing parts that meet evolving industrial demands.

Key considerations include mechanical strength, corrosion resistance, weight, cost, ease of fabrication, and the intended environmental conditions of the product.

Galvanized steel and aluminum are preferred for outdoor applications due to their resistance to rust and corrosion, providing long-lasting protection under various weather conditions.

Not all metals are suitable; the metal must have properties such as good formability, weldability, and appropriate thickness ranges to be effectively used in sheet metal fabrication.

Stainless steel offers superior corrosion resistance, higher strength, and a more attractive finish, making it ideal for environments requiring durability and hygiene; however, it is typically more expensive and harder to machine.

Common surface finishes include anodizing (mainly for aluminum), powder coating, galvanizing, and painting, which enhance corrosion resistance, improve aesthetic appeal, and prolong the lifespan of sheet metal parts.

[1](https://www.lsrpf.com/blog/what-materials-are-used-in-sheet-metal-fabrication)

[2](https://gilchriststeels.co.uk/the-full-guide-to-sheet-metal-fabrication/)

[3](https://www.facturee.de/en/material-selection-for-sheet-metal-working-your-comprehensive-guide/)

[4](https://revelation37.com/2023/10/16/sheet-metal-fabrication--a-comprehensive-guide/)

[5](https://ameritex.com/2022/11/03/guide-to-common-materials-in-sheet-metal-fabrication/)

[6](https://endura-steel.com/comprehensive-guide-to-sheet-metal-understanding-materials-dimensions-and-fabrication-techniques/)

[7](https://geomiq.com/sheet-metal-guide/)

[8](https://www.vicla.eu/en/blog/master-sheet-metal-materials)

[9](https://www.rapiddirect.com/blog/sheet-metal-fabrication-design-guide/)

[10](https://adslaser.co.uk/common-metals-used-in-sheet-metal-fabrication/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal