Views: 222 Author: Amanda Publish Time: 2025-09-28 Origin: Site

Content Menu

● Understanding 3D Printing Quality Control

>> Key Stages of Quality Control in 3D Printing

● Why Choose a Professional 3D Printing Manufacturer?

● How Professional Quality Control Impacts Your Product

● Tools and Technologies Used in 3D Printing Quality Control

● Common Challenges in 3D Printing Quality and How Professional Services Address Them

● Visual Demonstrations and Video Content in Quality Control

● The Role of OEM Services in 3D Printing Quality Control

● The Future of 3D Printing Quality Control

● Frequently Asked Questions (FAQ)

>> 1. How does 3D printing quality control differ between prototyping and mass production?

>> 2. What materials commonly require special quality control in 3D printing?

>> 3. Can 3D printing quality control detect internal structural defects?

>> 4. What certifications support 3D printing quality assurance?

>> 5. How long does the quality control process typically take?

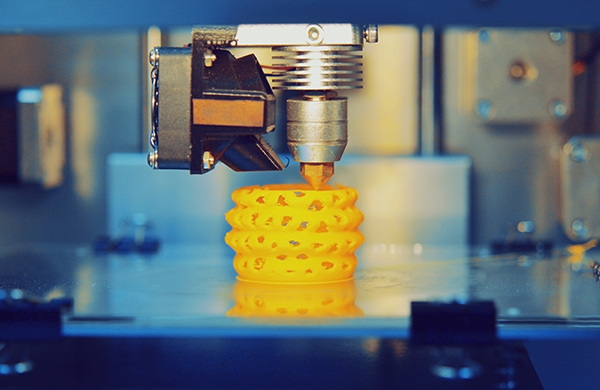

In today's fast-evolving manufacturing landscape, 3D printing has emerged as a revolutionary technology, transforming prototyping, production, and product development processes. For businesses relying on 3D printing services, quality control is a critical factor. Ensuring that the delivered parts meet exact specifications, maintain structural integrity, and exhibit flawless finishing can make or break a project. When working with a professional manufacturer like Shangchen, understanding what constitutes effective 3D printing quality control helps set expectations for reliability and performance.

Quality control in 3D printing encompasses a range of procedures and standards applied to monitor and improve the accuracy, repeatability, and consistency of printed parts. Unlike traditional manufacturing methods, 3D printing requires specific protocols because of variables like material properties, printer calibration, environmental factors, and post-processing techniques.

1. Pre-Printing Checks

Before the printing process begins, several critical assessments are performed to set the foundation for quality production. File validation confirms that 3D design files are accurate, complete, and free of geometry errors to avoid defects during printing. Material assessment ensures that the selected polymers, metals, or resins meet designated quality specifications and are compatible with the printer and intended application. Printer calibration includes verifying nozzle alignment, temperature controls, bed leveling, and machine maintenance to ensure optimal performance.

2. In-Process Monitoring

During printing, continuous monitoring mitigates risks of defects emerging mid-production. Real-time monitoring systems integrate cameras and sensors to observe the print layer by layer, detecting issues such as layer misalignment, under-extrusion, or warping promptly. Environmental controls stabilize temperature and humidity levels within the print chamber, as varying atmospheric conditions can influence material behavior and bonding quality.

3. Post-Printing Inspection

Once printing completes, parts undergo thorough inspection for any visual or dimensional inconsistencies. Visual examination identifies surface flaws like bubbling, incomplete boundaries, or irregular coloring. Dimensional accuracy is assessed using precision instruments such as calipers and coordinate measuring machines (CMM) to verify adherence to tight tolerance limits, ensuring parts fit and function as intended. Mechanical testing evaluates attributes including tensile strength, flexibility, and fatigue resistance, particularly important for functional or load-bearing components.

4. Finishing and Packaging Quality Check

Final finishing processes such as sanding, polishing, painting, or coating significantly impact both aesthetic appeal and part durability. A final quality check ensures that these treatments meet client standards and that components are packaged securely to avoid damage during shipment.

Partnering with a professional 3D printing manufacturer like Shangchen offers substantial benefits by integrating cutting-edge manufacturing technology and comprehensive quality control systems.

- Industrial-Grade Equipment: Professional manufacturers employ high-end 3D printers capable of producing high-resolution parts with consistent layer deposition and minimal errors. This equipment supports a diverse material portfolio, from advanced polymers to metals and composites.

- Rigorous Quality Management: Implementation of structured quality management systems ensures all production and inspection processes comply with international standards such as ISO 9001, guaranteeing reliability and traceability across production batches.

- Technical Expertise: Skilled engineers and technicians optimize designs for manufacturability, select suitable materials, set precise printer parameters, and troubleshoot potential issues before they affect production yields.

- Comprehensive OEM Services: Whether producing prototypes or high-volume precision parts, professional manufacturers offer tailored OEM support ranging from customization, confidential IP handling, to global logistics management. This enables overseas brands, wholesalers, and producers to scale operations efficiently while maintaining product integrity.

High standards in quality control directly translate into tangible advantages for your products and business reputation.

- Consistency: Every part produced matches prototype specifications exactly, enabling reliable assembly and performance in final applications.

- Longevity: Strict control over materials and processes ensures products can endure operational stresses, reducing failures and lowering maintenance costs.

- Aesthetic Perfection: Attention to surface finish and color fidelity enhances the product's market appeal, crucial for consumer-facing items.

- Faster Turnaround: Minimizing errors and reworks accelerates production cycles, supporting faster time-to-market and responsiveness to demand fluctuations.

Manufacturers employ an array of sophisticated instruments and techniques to guarantee 3D printing quality:

- Coordinate Measuring Machines (CMM): These devices provide extremely precise measurements of physical part dimensions, verifying adherence to design tolerances.

- 3D Scanners: By digitally capturing the entire geometry of printed components, scanners compare actual outputs to original CAD models, highlighting any areas of deviation.

- Microscopes and Visual Inspection Stations: These enable quality control teams to detect minute surface imperfections, such as layer separation or micro-cracks, that might impact durability.

- Environmental Sensors: Monitoring systems track conditions such as temperature, humidity, and particulate matter within print chambers for consistent environments vital to quality outcomes.

- Automated Cameras and AI Inspection: Increasingly, advanced cameras coupled with AI algorithms identify print defects during production, allowing rapid corrective action.

Materials such as thermoplastics and metals can warp due to uneven cooling, creating dimensional distortion. Professionals control build chamber environments tightly and utilize optimized material blends to mitigate this.

Poor bonding between successive layers may cause part weakness. Optimized printer settings for temperature, extrusion speed, and layer thickness are essential to ensure strong inter-layer adhesion.

Rough or uneven surfaces reduce both appearance and function; advanced post-processing techniques like tumbling, sanding, and coating significantly enhance surface quality.

Maintaining uniform quality over large production runs demands rigorous documentation of processes, continuous monitoring, and systematic calibration between batches to limit variability.

Visual tools help clients grasp the complexity and precision of quality control in 3D printing. Examples include:

- Time-lapse videos showing layer-by-layer building of parts to demonstrate printer accuracy and speed.

- Before-and-after visuals highlighting surface finishing processes and improvements.

- Infographics explaining key measurement procedures like tolerance checks.

- Demonstrations of mechanical performance testing to prove part durability.

Providing such multimedia content boosts transparency, educates customers, and strengthens confidence in manufacturer capabilities.

OEM services emphasize delivering customized manufacturing solutions under clients' brand identities while meeting stringent quality standards. Key aspects include:

- Material and process customization based on client needs.

- Secure handling of sensitive design files and intellectual property.

- Comprehensive certification and documentation accompanying shipments.

- Efficient supply chain management for global wholesale and distribution.

Shangchen's hybrid expertise in rapid prototyping, CNC machining, and 3D printing uniquely positions it to support clients from prototype to precision batch production with consistent quality.

Emerging technologies promise to elevate 3D printing quality control further:

- AI-Driven Defect Detection: Computer vision and machine learning enable instant identification of subtle manufacturing defects.

- Advanced Sensor Integration: Multi-sensor arrays monitor temperature, humidity, and stress indicators throughout the printing process in real time.

- Smart Materials: New printable materials equipped with self-healing or adaptive properties could reduce defects and prolong part life.

- Blockchain Traceability: Using blockchain to document every production step enhances transparency and accountability in supply chains.

These innovations will empower manufacturers to uphold increasingly rigorous quality benchmarks in an expanding variety of applications.

Reliable, high-quality 3D printing manufacturing depends on integrated and thorough quality control at every stage — from pre-printing checks to final packaging. Experienced manufacturers like Shangchen apply state-of-the-art equipment, skilled workforce, and rigorous inspection protocols to ensure that every part meets design intent with precision and artistry. This dedication yields components that deliver on functionality, durability, and aesthetic appeal, empowering global brands and wholesalers with confidence in their supply chain. As additive manufacturing technologies evolve, continuous improvements in quality control will further solidify 3D printing's role as a cornerstone of modern manufacturing.

Prototyping focuses on rapid iterations and verifying design concepts, often with more leniency on tolerances. Mass production demands tightly controlled processes to ensure dimensional consistency and defect reduction across large quantities.

Metals, high-performance polymers, and composites typically require advanced quality control due to their sensitivity to thermal stresses, bonding quality, and mechanical properties.

Yes. Techniques such as X-ray computed tomography (CT) scanning provide non-destructive internal inspections to reveal voids, cracks, or inclusions invisible to surface checks.

Standards like ISO 9001 for quality management systems and ISO/ASTM 52900 for additive manufacturing establish globally recognized guidelines that professional manufacturers follow.

The duration varies with part complexity and batch size. Simple prototypes may only require a few hours of inspection, while complex or bulk production can take several days due to exhaustive testing and documentation.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal