Views: 222 Author: Amanda Publish Time: 2025-10-02 Origin: Site

Content Menu

● Why Choosing the Right Injection Molding Manufacturer Matters

● Key Criteria to Identify Quality Injection Molding Manufacturers

>> Advanced Equipment and Technology

>> Material Selection and Handling

● Shangchen: A Leading Injection Molding Manufacturer

● Injection Molding Process Overview

● Common Challenges in Injection Molding and Solutions

● Best Practices to Assess Injection Molding Manufacturers

● The Role of Technology in Modern Injection Molding

● Environmental and Sustainability Considerations

● FAQ

>> 1. What types of plastics are commonly used in injection molding?

>> 2. How long does the injection molding process take?

>> 3. Can injection molding manufacturers handle low and high-volume orders?

>> 4. How do manufacturers ensure precision and quality?

>> 5. What additional services do injection molding manufacturers offer?

Injection molding is a cornerstone manufacturing process for countless industries, shaping complex plastic parts with precision and efficiency. However, choosing the right injection molding manufacturer is crucial for ensuring product quality, timely delivery, and cost-effectiveness. In this comprehensive article, we explore how to identify the best injection molding manufacturers, what factors define quality and reliability, and how services like those offered by Shangchen can meet the demanding needs of global brands and producers.

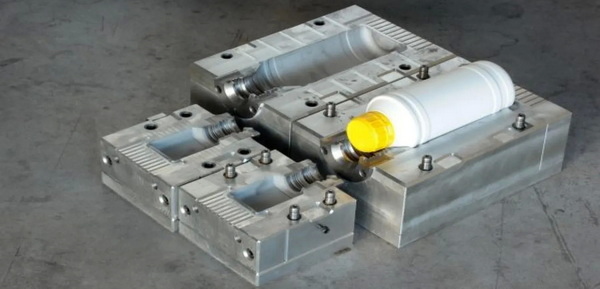

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure, cooled to form the desired shape, and then ejected as a finished part. This process provides high-volume production with consistent quality and excellent surface finishes. Common applications include automotive parts, consumer products, electronics enclosures, and medical devices.

The versatility of injection molding comes from the ability to mold parts of various sizes, complexities, and materials, including thermoplastics, thermosets, and elastomers. This process supports a range of finishes and colors, making it ideal for both functional and aesthetic components.

Selecting the best injection molding manufacturer impacts every aspect of your product lifecycle:

- Consistency: Poor quality control can lead to defects, excessive scrap, and rework, harming your brand reputation and increasing costs.

- Precision: Tight tolerances require expert machine operation and quality molds to ensure parts fit perfectly within assemblies.

- Cost: Efficient processes, including optimized cycle times and minimal scrap, lower production costs.

- Lead Time: Reliable manufacturers meet deadlines, preventing costly delays in product launch.

- Customization: Skilled manufacturers offer design feedback, mold development expertise, and prototyping capabilities, enabling tailored solutions that optimize functionality and manufacturability.

Choosing a trusted partner minimizes risks and drives product success, enabling brands to focus on innovation rather than production challenges.

Look for manufacturers with proven industry experience and specialized knowledge in injection molding. Their expertise often reflects in their ability to handle complex projects, select the right materials, and troubleshoot process issues quickly. Manufacturers that have served multiple sectors — automotive, medical, consumer electronics, and more — bring a wealth of shared knowledge about design for manufacturability, mold maintenance, and process optimization.

Additionally, engineers familiar with the latest injection molding technologies and materials trends can offer valuable insights during product development, reducing costly redesigns.

Top manufacturers invest in state-of-the-art injection molding machines with variable injection pressure, temperature control, and multi-axis robotic handling. Precise machine control ensures better dimensional accuracy and quality repeatability.

Apart from molding machines, advanced CNC machining centers and mold-making technologies play a crucial role in manufacturing precise molds with low wear, directly influencing part quality and mold longevity.

Moreover, some manufacturers integrate automation for part handling, quality inspection, and packaging — improving throughput and reducing manual errors. Real-time data monitoring systems further support consistent production by detecting deviations early.

Leading companies provide a wide range of services besides injection molding itself, including:

- Prototype development with rapid timelines to validate designs before full-scale mold making

- CNC machining for complex tooling and secondary operations

- 3D printing and rapid prototyping to produce concept models or master patterns

- Mold design and manufacturing with CAD/CAM integration and precision tooling

- Secondary operations such as trimming, drilling, painting, plating, and assembly

Providing these services under one roof streamlines coordination, reduces lead times, and maintains responsibility for final product quality.

Check if the manufacturer follows rigid quality standards such as ISO 9001 or IATF 16949 certification. These standards enforce thorough process control, traceability, and continuous improvement frameworks that minimize defect rates and ensure customer satisfaction.

A robust quality management system includes:

- Incoming material inspection with certificates of conformity

- In-process inspections using calibrated instruments

- Final dimension checks with CMM or optical systems

- Statistical process control (SPC) to monitor key variables

- Corrective and preventive action (CAPA) procedures

Strong quality processes prevent issues before parts reach the customer.

Superior injection molding manufacturers understand polymer properties and maintain secure storage with moisture and contamination controls for sensitive materials like ABS, polypropylene, or engineering plastics. Proper drying and handling prevent defects like bubbles, sink marks, or warpage.

Manufacturers should also be able to advise on material grades, suggest compatible additives or fillers, and test samples to verify properties such as strength, flexibility, and color consistency.

Shangchen is a top-tier OEM injection molding service provider based in China. Combining rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold production, Shangchen offers a full manufacturing ecosystem tailored to overseas brands, wholesalers, and producers.

- Full Vertical Integration: Quick transitions from design through prototyping to finished parts reduce both costs and lead times.

- Expert Engineering Team: Skilled in tool design and injection process optimization, capable of solving complex production challenges.

- Quality Focus: Adherence to international standards and rigorous quality control with advanced machinery and in-line inspections.

- Custom Solutions: Tailored production runs provide flexibility from prototypes to high-volume batches.

- Global OEM Partnerships: Experienced supporting diverse international quality, packaging, and logistics requirements.

These capabilities make Shangchen a comprehensive injection molding partner that helps clients achieve reliable, cost-effective production with high standards.

Injection molding typically involves these key steps:

1. Material Preparation: Plastic pellets are dried to remove moisture, preventing defects during melting.

2. Injection: Molten plastic is injected into the mold cavity under high pressure.

3. Cooling: The injected plastic cools and solidifies within the mold, setting the final shape.

4. Ejection: The mold opens, and the part is ejected gently using pins or air blasts.

5. Post-Processing: Additional finishing like trimming, polishing, painting, or assembly is performed.

Manufacturers must optimize cycle time — balancing injection pressure, cooling duration, and mold design — to achieve maximum throughput without sacrificing quality.

Injection molding also presents various challenges:

- Warpage and Shrinkage: Caused by uneven cooling of thick vs. thin sections. Manufacturers combat this with careful mold design, balanced cooling channels, and optimized material choice.

- Short Shots: Result from insufficient injection pressure or material flow issues. Process adjustments and mold venting reduce occurrence.

- Flash: Excess material leakage at mold parting lines due to insufficient clamping force or worn molds. Routine mold maintenance prevents flash.

- Sink Marks: Surface depressions from rapid cooling or thick sections. Mold redesign and resin additives can improve surface finish.

- Dimensional Stability: Tolerance issues can arise from machine calibration or material variance. Precision tooling and SPC help maintain tight tolerances.

Experienced manufacturers implement advanced mold flow simulations, regular machine calibration, and quality inspections to minimize these defects.

When choosing a manufacturer, consider:

- Sample Evaluations: Request physical or digital samples to verify surface finish, tolerance, and mechanical properties.

- Certifications: Confirm adherence to certified quality management practices.

- Material Expertise: Ensure experience with the plastics you plan to use and access to technical support.

- Customer References: Contact existing clients to gauge reliability, communication, and post-delivery support.

- Communication: A responsive and collaborative manufacturer is key to efficient problem-solving.

- Capacity: Verify production volume capability, machinery availability, and contingency plans for scaling orders or handling rush jobs.

Technology advancements are revolutionizing injection molding quality and efficiency:

- CAD and CAE Software: 3D modeling and finite element analysis enable designers to optimize parts and molds before production.

- Simulation Tools: Mold flow analysis predicts how molten plastic will behave, identifying potential defects early.

- Automation: Robotic part unloading, in-line inspection cameras, and automated packaging increase throughput and reduce human error.

- Machine Monitoring: IoT sensors collect data on temperature, pressure, and cycle times, alerting operators to deviations.

- Additive Manufacturing: 3D printing of molds and prototypes accelerates product development cycles and facilitates rapid design changes.

Embracing these technologies elevates product quality, reduces scrap rates, and shortens development timelines.

Sustainability is becoming a priority in injection molding. Leading manufacturers:

- Use recyclable and bio-based plastics to reduce environmental impact.

- Minimize waste through process optimization and regrinding scrap material.

- Adopt energy-efficient machines that consume less power.

- Implement water recycling in cooling systems.

- Comply with regulations such as RoHS and REACH for chemical safety.

Partnering with environmentally responsible manufacturers aligns with global sustainability goals and enhances brand value in eco-conscious markets.

Choosing the best injection molding manufacturer is vital for producing high-quality, consistent, and cost-effective plastic parts. Evaluating manufacturers based on experience, technology, quality management, and breadth of services ensures a reliable supply chain and superior outcomes. Companies like Shangchen demonstrate how full-service manufacturers with advanced capabilities and extensive OEM experience can fulfill the complex demands of modern product development and production. Leveraging such partners results in faster production cycles, reduced risks, optimized costs, and products built to succeed in competitive markets worldwide.

Common plastics include ABS, polypropylene (PP), polyethylene (PE), polystyrene (PS), and engineering thermoplastics like polycarbonate (PC) and nylon. Each material offers different strength, flexibility, and temperature characteristics suited for specific applications.

Cycle times typically range from a few seconds to a few minutes, depending on part complexity, size, and material cooling requirements. Efficient manufacturers optimize cycle times to maximize throughput without sacrificing quality.

Yes, reputable manufacturers like Shangchen manage both small prototype runs and scale to high-volume batch production, offering flexibility for diverse project needs from initial validation to large-scale manufacturing.

Through precise mold design, advanced injection molding machines, rigorous quality control inspections such as CMM measurement, and compliance with international certifications like ISO 9001 or IATF 16949.

Many provide CNC machining, rapid prototyping, mold design and manufacturing, sheet metal fabrication, 3D printing, surface finishing, painting, plating, and assembly services, offering comprehensive manufacturing solutions under one roof.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product