Views: 222 Author: Amanda Publish Time: 2025-07-10 Origin: Site

Content Menu

● Overview of CNC Machining in the UK

● Key Industries Served by CNC Machining Manufacturers and Suppliers

● Top CNC Machining Manufacturers and Suppliers in the UK

>> A&M EDM

● What Sets UK CNC Machining Apart?

● The Role of Technology in Modern CNC Machining

● How to Choose the Right CNC Machining Supplier

● Future Trends in CNC Machining in the UK

● FAQ

>> 1. What are the main advantages of using CNC machining manufacturers and suppliers in the UK?

>> 2. How do I select the best CNC machining supplier for my needs?

>> 3. What industries benefit most from CNC machining services in the UK?

>> 4. Can UK CNC machining suppliers handle both prototyping and mass production?

>> 5. What is the impact of automation on CNC machining in the UK?

The United Kingdom stands as a global leader in advanced manufacturing, with its CNC machining sector at the forefront of innovation and precision engineering. From aerospace to medical devices, the demand for high-quality CNC machining manufacturers and suppliers in the UK continues to grow. This article delves deep into the landscape of CNC machining in the UK, exploring the top manufacturers and suppliers, their capabilities, the industries they serve, and the latest trends shaping the industry. Along the way, you'll gain a comprehensive understanding of this dynamic field and learn how to choose the best partners for your manufacturing needs.

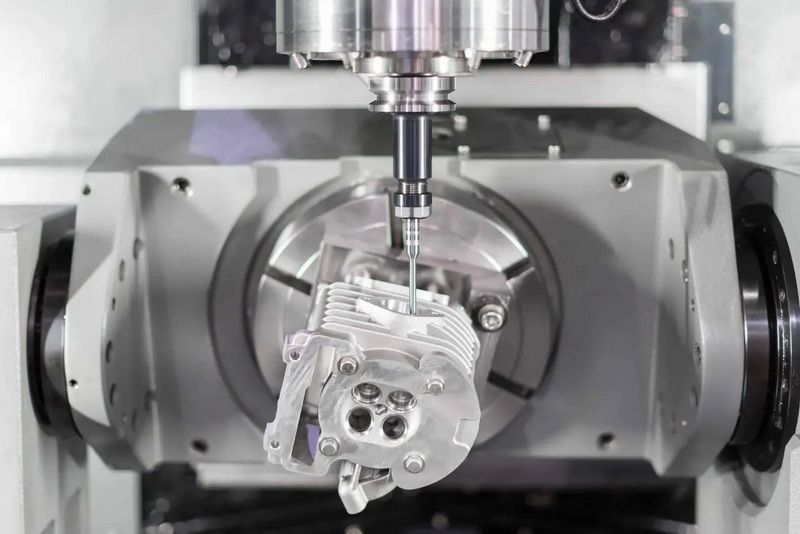

CNC (Computer Numerical Control) machining is a process that uses computer-controlled tools to manufacture precise parts and components from a wide range of materials. The UK's CNC machining manufacturers and suppliers have earned a reputation for delivering exceptional quality, innovation, and reliability.

The UK's manufacturing sector is built on a foundation of technical expertise, with CNC machining playing a vital role in supporting industries such as automotive, aerospace, medical, defense, and electronics. The country's CNC machining manufacturers and suppliers are known for their ability to handle complex projects, offer rapid prototyping, and provide scalable solutions for both small and large production runs.

CNC machining in the UK benefits from a rich engineering heritage combined with a modern industrial infrastructure. This synergy allows manufacturers to produce parts with extremely tight tolerances and complex geometries, meeting the rigorous demands of cutting-edge industries. Moreover, UK suppliers are increasingly focusing on integrating digital manufacturing techniques and automation to improve efficiency and reduce turnaround times.

The versatility and precision of CNC machining make it indispensable across various sectors. Some of the most prominent industries served by CNC machining manufacturers and suppliers in the UK include:

- Aerospace: The aerospace industry demands components that can withstand extreme conditions while maintaining flawless precision. UK CNC machining suppliers produce parts for aircraft engines, landing gear assemblies, turbine blades, and structural components, all manufactured to the highest standards to ensure safety and performance.

- Automotive: From engine components to transmission parts and bespoke prototypes, CNC machining supports the automotive sector's need for precision and durability. UK suppliers cater to both mainstream manufacturers and niche performance vehicle producers, offering rapid prototyping and volume production.

- Medical Devices: The medical sector requires components with exceptional accuracy and biocompatibility. CNC machining manufacturers in the UK produce surgical instruments, orthopedic implants, diagnostic equipment housings, and other critical parts, often working with specialized materials like titanium and medical-grade stainless steel.

- Oil & Gas: The harsh environments of oil and gas extraction necessitate robust and reliable components. CNC machining suppliers provide high-strength fittings, valves, drilling components, and safety-critical parts designed to meet stringent industry standards.

- Electronics: The electronics industry relies on CNC machining for producing enclosures, connectors, heat sinks, and other components that require precise dimensions and fine finishes.

- Defense: Defense applications demand components with exacting specifications and reliability. UK CNC machining manufacturers supply parts for armaments, communications equipment, and support systems, often adhering to strict security and quality protocols.

XYZ Machine Tools is renowned for its advanced CNC machining capabilities, offering a wide range of services from prototyping to full-scale production. Their state-of-the-art facilities are equipped with the latest CNC mills, lathes, and multi-axis machines, ensuring high precision and consistency. XYZ's commitment to innovation and customer satisfaction has earned them a strong reputation across various sectors.

Hemlock Engineering specializes in precision CNC milling and turning, serving industries such as aerospace, medical, and automotive. Their team of skilled engineers leverages advanced CAD/CAM software to deliver complex parts with tight tolerances. Hemlock's focus on quality and flexibility allows them to handle both small batch runs and large-scale production efficiently.

Penta Precision is a leading CNC machining supplier known for its commitment to quality and customer satisfaction. They offer a broad spectrum of services, including CNC milling, turning, and surface finishing, catering to both prototyping and production needs. Their modern facilities and experienced workforce enable them to meet demanding project requirements with speed and accuracy.

A&M EDM combines CNC machining with electrical discharge machining (EDM) to create intricate components for high-tech industries. Their expertise in both conventional and unconventional machining processes sets them apart in the UK market. This dual capability allows them to produce complex geometries that are difficult to achieve with traditional methods alone.

Qualiturn Products specializes in high-volume CNC turning and milling, supporting clients in the automotive, electronics, and defense sectors. Their automated production lines ensure rapid turnaround and consistent quality, making them a preferred partner for companies requiring reliable and scalable manufacturing solutions.

Precision Products UK delivers custom CNC machining solutions for clients requiring complex geometries and high-performance materials. Their investment in automation and quality control guarantees reliable results. They focus heavily on continuous improvement and adopting cutting-edge technologies to maintain their competitive edge.

Sub-CNC Precision is a trusted name in the supply of turned and milled parts, offering flexible solutions for both small and large batch orders. Their commitment to continuous improvement keeps them at the cutting edge of CNC technology. They are known for their excellent customer service and ability to adapt quickly to changing project requirements.

The UK's CNC machining manufacturers and suppliers distinguish themselves through a combination of technical expertise, investment in advanced technology, and a strong focus on quality assurance. Key differentiators include:

- Highly Skilled Workforce: The UK boasts a pool of experienced engineers and machinists who excel at solving complex manufacturing challenges. Their expertise ensures that even the most intricate designs can be realized with precision.

- Advanced Equipment: Leading suppliers utilize the latest CNC machines, including 5-axis and multi-spindle systems, to achieve exceptional accuracy and efficiency. This equipment allows for the production of complex parts with minimal setup times.

- Quality Standards: Rigorous quality control processes, often certified to ISO 9001 or AS9100, ensure that every component meets stringent industry requirements. Many suppliers incorporate in-process inspection and final validation to guarantee defect-free parts.

- Innovation: UK manufacturers are at the forefront of adopting new materials, processes, and digital manufacturing techniques. This includes the integration of additive manufacturing with CNC machining, enabling hybrid approaches that expand design possibilities.

- Customer-Centric Approach: UK CNC machining suppliers emphasize strong communication, flexibility, and tailored solutions, fostering long-term partnerships with clients worldwide.

Technological advancements have revolutionized the CNC machining landscape in the UK. Key innovations include:

- CAD/CAM Integration: Seamless integration of design and manufacturing allows for rapid prototyping and reduced lead times. Engineers can simulate machining processes digitally, optimizing tool paths and minimizing errors before production begins.

- Automation: Automated loading, tool changing, and inspection systems enhance productivity and reduce human error. Automation also enables 24/7 manufacturing, increasing output without compromising quality.

- Additive Manufacturing: The combination of CNC machining with 3D printing enables hybrid manufacturing, offering new possibilities for complex parts. For example, 3D printing can produce lightweight internal structures that CNC machining then finishes to precise specifications.

- Digital Twin Technology: Virtual simulations of the machining process help optimize tool paths, predict maintenance needs, and minimize waste. This technology supports continuous improvement and reduces downtime.

- Smart Manufacturing: The adoption of Industry 4.0 technologies, including IoT sensors and AI-driven analytics, allows manufacturers to monitor machine health, optimize production schedules, and improve overall efficiency.

Selecting the right CNC machining manufacturer or supplier is crucial for ensuring project success. Consider the following factors:

- Technical Capability: Assess the supplier's equipment, software, and experience with your required materials and tolerances. Ensure they have a proven track record in your industry.

- Quality Assurance: Look for certifications and documented quality control processes. Ask about inspection methods, traceability, and adherence to standards.

- Lead Times: Evaluate the supplier's ability to meet your deadlines, especially for urgent or high-volume orders. Discuss their capacity and flexibility.

- Customer Service: Strong communication and support are essential for a smooth project experience. A responsive supplier can help troubleshoot issues and provide updates throughout the manufacturing process.

- Cost Efficiency: Balance competitive pricing with the value offered in terms of quality and reliability. Beware of suppliers who cut corners to reduce costs.

- Location and Logistics: Consider the supplier's proximity to your operations and their shipping capabilities, especially if you require just-in-time delivery.

- Sustainability Practices: Increasingly, companies seek suppliers committed to environmentally responsible manufacturing, including waste reduction and energy efficiency.

The future of CNC machining in the UK is shaped by several key trends:

- Sustainable Manufacturing: Emphasis on eco-friendly processes, material recycling, and energy efficiency is becoming a priority. Suppliers are adopting greener technologies and reducing carbon footprints.

- Smart Factories: The rise of Industry 4.0 means more factories will feature interconnected machines, real-time data analytics, and AI-driven decision-making to optimize production.

- Customization: Increasing demand for bespoke components tailored to specific applications drives suppliers to offer more flexible and agile manufacturing solutions.

- Global Supply Chains: UK suppliers are expanding their reach, serving international clients with fast shipping and responsive service, while also adapting to geopolitical changes and supply chain disruptions.

- Material Innovation: New alloys, composites, and bio-based materials are being integrated into CNC machining processes, expanding the range of applications and improving performance.

- Training and Workforce Development: To keep pace with technological advancements, ongoing training and skill development for machinists and engineers will be critical.

The UK is home to some of the world's most advanced and reliable CNC machining manufacturers and suppliers. Their expertise, commitment to quality, and embrace of cutting-edge technology make them the partners of choice for industries demanding precision and innovation. As the sector continues to evolve, UK-based suppliers are well-positioned to meet the challenges of tomorrow, delivering exceptional value to clients across the globe. Whether you require rapid prototyping, complex part manufacturing, or high-volume production, the UK's CNC machining industry offers unparalleled capabilities and service.

UK CNC machining manufacturers and suppliers offer high technical expertise, advanced technology, strict quality control, and reliable delivery times, making them ideal partners for complex and demanding projects. Their strong engineering heritage and commitment to innovation ensure superior results.

Consider factors such as technical capability, quality certifications, lead times, customer service, and cost efficiency. Request sample parts and, if possible, visit the supplier's facility to assess their operations firsthand. Clear communication and transparency are also vital.

Key industries include aerospace, automotive, medical devices, electronics, oil & gas, and defense. These sectors rely on the precision and reliability provided by top CNC machining manufacturers and suppliers to meet stringent standards and complex design requirements.

Yes, many UK CNC machining manufacturers and suppliers offer flexible services, ranging from rapid prototyping to high-volume production. This flexibility allows clients to scale their manufacturing as needed without changing suppliers.

Automation has significantly improved efficiency, consistency, and quality in CNC machining. It enables manufacturers to handle complex projects with shorter lead times, reduced human error, and increased productivity, supporting the demands of modern manufacturing.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes